DIY W Rails

-

Since TFL announced the WTF rails I really liked the look of them. They give the board just that little extra flair. However I think I could probably build my own and save myself a lot of money in the process.

I don't have access to a mill but from my research aluminium brazing is as strong as the aluminium itself so any weld I do should be up to the task. Since the rails are almost identical to a standard sized Aluminium U Channel (38.1mm x 19mm x 3.2mm) I should be able to use that.

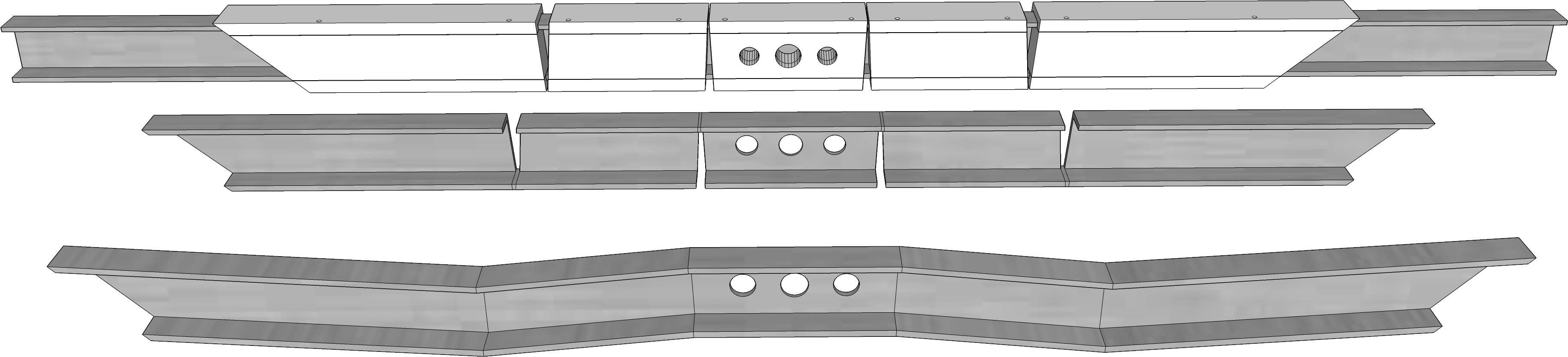

To help with strength if I just cut wedges out of the channel, then bend and braze the seams I should get at least one continuous section of material across a brazed joint. Below is sort of what I'm thinking using some printed templates to help get the cuts right.

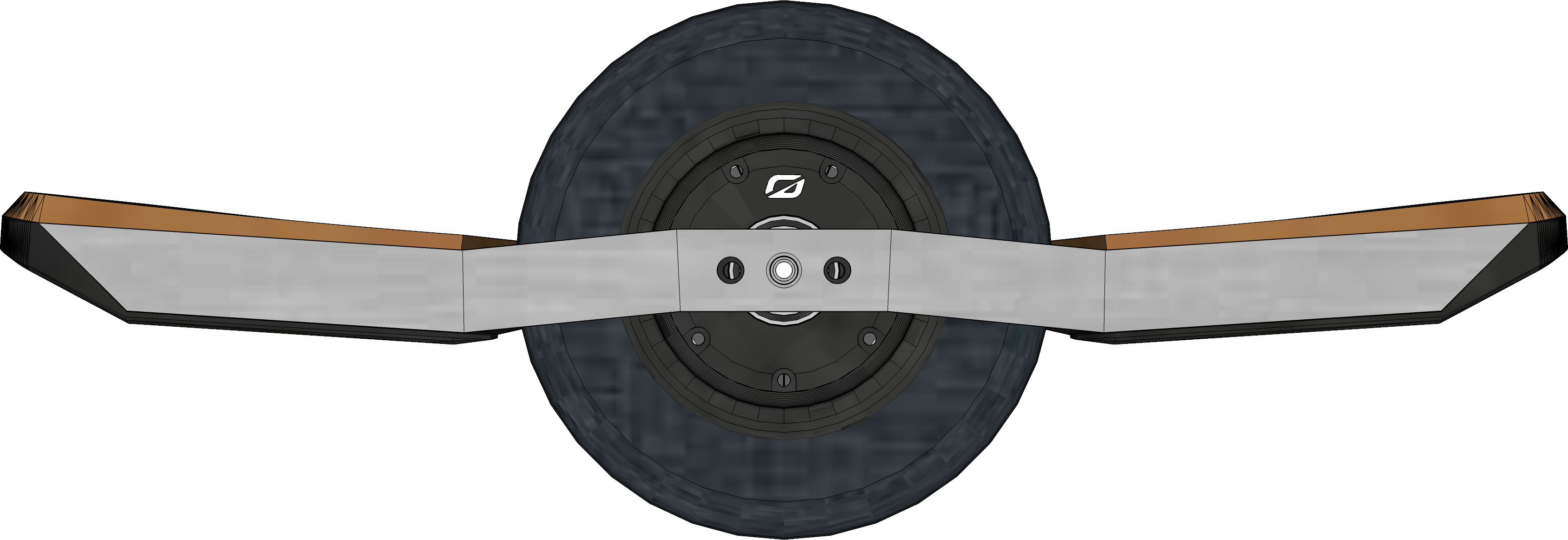

Hopefully that helps show my idea better than the word soup.Currently they're modelled to just fit as standard to the board with no extra space given however that I'm considering lengthening them a little for slightly bigger tyres and to give a bit more control since I ride almost end to end.

I already have 2x 1000mm lengths of the U-Channel I mentioned earlier from a while back but haven't yet cut it since I'm toying with amending the design more. Any thoughts before I commit?

Still a few projects I have the printer working on so won't have the templates done for a while yet still but figured passing the idea by everyone else might introduce some cooler or better ideas.

Edit : Dumb thought, could keep the name as WTF but for these it means "Wow They're Fake" instead of "Wow They're Fast" ;)

-

How on earth you undertake so many projects simultaneously?

If you're particularly keen to W-shape - might wanna check WBeams (by 4820 Obligatory) as well.@Lia said :

... from my research aluminium brazing is as strong as the aluminium itself so any weld I do should be up to the task. ...

You sure? I never knew that! Always thought there's a reason for why all aftermarket rails are milled from billet aluminium. Which in turn is the reason they all end up being rather expensive form material expense wize.

-How would you think of filling the hollow contact area with axle carriers?

-

@sirgu said in DIY W Rails:

How on earth you undertake so many projects simultaneously?

An excessively spontaneous personality ;) I can't help but start new things, really enjoy having lots of things to work on at any given time so I don't find myself getting burnt out. On the flipside projects can get shelved for a while.

I didn't believe it till I watched a few videos and in some cases the braze/weld outlives the material itself?!

https://weldingtroop.com/aluminum-brazing-advantages-over-welding/Permanent Bond

A significant advantage of aluminum brazing is that, like fusion welding, brazing is a great choice for providing a permanent bond between two metal pieces. If brazing is performed correctly, the joint should be just as strong as the two pieces of metal being joined together.Because it can provide a permanent fusion between pieces of metal as quickly as welding, brazing is a popular technique for metalworking when two pieces must be joined with no loss of tensile strength at the bond.

I assume milling is a much easier process to automate hence why it's done that way however I'll find out soon enough if a decent drop tears either the battery or controller segments clean off xD

As for the axle carriers (much better terminology than I was using, yoink ;p ) I'll do like I did on the XS and cut to size some aluminium stock, pillar drill out the holes then braze into place. Should be easier on a full scale version rather than that half scale nightmare ;)

-

@lia I did aluminum brazing or aluminum soldering. It's good for low strength overlap joints, not so good for high strength welds. Especially weak on butt joints.

I use it mainly for ornamental work or making mini bike gas tanks. Here's a gas tank I made, good for overlapping joints, the end cap on this gas tank is a lap joint.

For your application , tig is best.

-

I recently had a chat with "Ponakka" on Reddit. The dude that indpired some of us to try the chinese seat sensor thing, very nice chap.

Anyway, he cut his stock rails at an angle and extended the rails by 5mm.

Used specialized dc tig. -

@Lemur @MacIak Thanks for the insight, appreciate getting some shared experience on these sorts of things :)

I’ll give it a shot brazed/soldered; possibly add a joining layer on the joints to help distribute the strain and avoid just a butt joint. If that fails my load test (stomping them on a curb) I’ll look at seeing if theres anyone near me with proper welding gear.

-

Yes - butt joint - that's the term! I could have came out with smth clumsy like "edge-against-edge" in further explanation efforts.

Saw in FB few months back as someone did his own TailRails (aka 7 Second Rails) out of OG rails the same method. Leaving the enormously robust seam inwards the channel to somewhat "support" the joint. It is not clearly known if the solution proved any right over time. Rather left questions.

-

@Lia (or anyone), do you know the angle for official, TFL WTF rails? I have always known my nose was high on my CBXR, but I rode it like 90% of the time, so I just got used to it. But, now I am riding my GT a lot, and the angle is kind of annoying. I also can't ride it backwards because it feels like the board is pointing down at slow speed and almost like I don't have pushback at high speed.

I leveled my board until the app said the angle was 0.0°. Then, I used a bubble level app on my phone to measure the angle of my rails, and they come to 1.77°. I think WTF rails are 3.5°, but that just comes from measuring pictures. So, I am wondering if finding a set of WTF rails used from someone upgrading to varials might not just be a perfect solution. It shouldn't make a difference, but I was on Mission when I did the tests.

Alternatively, does anyone know of a way to recalibrate the board to understand what true 0.0° is?

Thanks for any help people can provide. I am hoping to get my answers here so I don't have to post to reddit.

-

@biell I based mine off some side-on images and got 3.7° of tilt so I imagine it's around that.

Other than the WTF tilt kit which is TFL's aftermarket lid that corrects the angle you would want to find a way to shim the controller to angle it in the housing whilst maintaining contact between the lid and controller so it can sink heat into it still.

I think @MacIak had some luck DIY'ing a setup.

-

@lia You know... For the right amount of counter-simping I could be convinced to send you my WTFs when I get my Varials. ;)

-

@lia Yep, I measured multiple images and kept getting between 3.5 and 3.7 so it must be in that range. The largest images I could find are 1000x1000 and in a lossy format, so not the most accurate.

I don't know that I have the skills to build a reverse TFL plate. I was hoping there was some magic thing you could do to reset the controller's understanding of level. I might post to Reddit and see if someone else knows of a way to get it to recai.

Thank you.

-

@biell said in DIY W Rails:

@Lia (or anyone), do you know the angle for official, TFL WTF rails?

@MacIak has 2 WTF rails (and in really few time, Varials), I guess he can measure whatever you need

-

@samuraipunch said in DIY W Rails:

For the right amount of counter-simping

Never any good at that.

Only ever managed Gold Nova 1 in CounterStrikeSimping : Global Offensive ;)As tempting as it would be my online flirting wouldn't be fair to wifey. Already has to tolerate a lot of my nonsense.

Which varials did you order btw? Those look pretty cool and useful for tire swaps.

-

Surfdado thinks it is 4.2° here: https://youtu.be/dXDav1OefNM?t=357

I have decided, at least for now, that the WTF rails aren't sufficiently close to my 1.77° that I would be able to ride in Mission. So, if I can't ride Mission, I might as well see if I can fix it with Custom.

Yesterday I went on a long ride at -1,-1,6 and that is surprisingly close to Flow on a GT for my board. I am not sure what Aggressiveness is closer to Mission, but the extra bump past mid helped the board lift the nose faster going uphill and keeping me from bottoming out in steep inclines. I guess, I was essentially riding in elevated all the time before.

I will probably play with Carvability -2 to 1 and see if a Stance Profile of like -0.8 or so is better.

If anyone has any ideas on the closest custom shaping to Mission, I would be interested in reviewing that. When it came out originally, I only played with it for a short period before deciding that Mission was just better.

Thanks in advance.

-

@biell Custom shaping will never be Mission. I played with so many settings but the weird surging just does not feel right. Now i just use plain Mission and ride level at pushback;)

The angle as i measure is 4deg. Have no digital gauge, just by hand.

-

@maciak Thanks, I agree, Mission is by far the best shaping. And, thanks for measuring.

I've known something was off for a long time, I stand on my tip-toes on my rear foot when waiting for traffic lights, to even things out. I also can't ride the board backwards b/c it is 3.54° in the other direction from what I am used to. But, I just dealt with it before.

My Plus is fine, but pushback starts so early on that thing, it wasn't that much different. But, now with the GT being level until 19MPH, the 1.77° on my XR is just really annoying and different.

I will try Reddit, and if they are no help, reach out to some Stoke Life people to see if I can fix it so I can go back to Mission. Alternatively, I could redo the repair on my 4208 and swap back down to that one.

-

@biell -- Riding pushback all the time on my Plus I put in a thick board for the back footpad and it helps.

-

@s-leon Actually it does lol. PB on + is a pita

-

@biell You could get a tiltkit or just diy tilt the controller? Needs about 4-5mm. It creates a different set of problems though. The TFL tiltkit killed a bunch of controllers (how is it kept silent?!). I suspect cause of a capacitor getting squeezed into the bottom of the box which i found out during own experimenting. I asked/adviced Jeff. He tactically avoided answering any questions about it.

-

@maciak I am afraid my skills might not be there for that. Also, I would have to tilt the other direction, which might mess up how the connectors line up with the holes in the back of the controller box.