@lia Hah, just chilling with Paddington lol.

It was deceptively cold, we had some blue sky and managed to dodge the showers.

We took a chance going this time of year but the roads and sights were pretty empty 😉

We had most of the remote places to ourselves 👍

Group Details

XR

XR Board Owners

Member List

-

RE: Onewheel Photoshoot Threadposted in Wall of Stoke

-

RE: Onewheel Photoshoot Threadposted in Wall of Stoke

@puzz360 Looks like a shockingly nice day for winter!

Did you stop at the pub there? Any good or just chilling with Paddington 😊 -

RE: Onewheel Photoshoot Threadposted in Wall of Stoke

It's been a while since I've got any slightly worthy shots... Yes, the weather has been as usual. Rainy.

Here's a few from a recent trip...

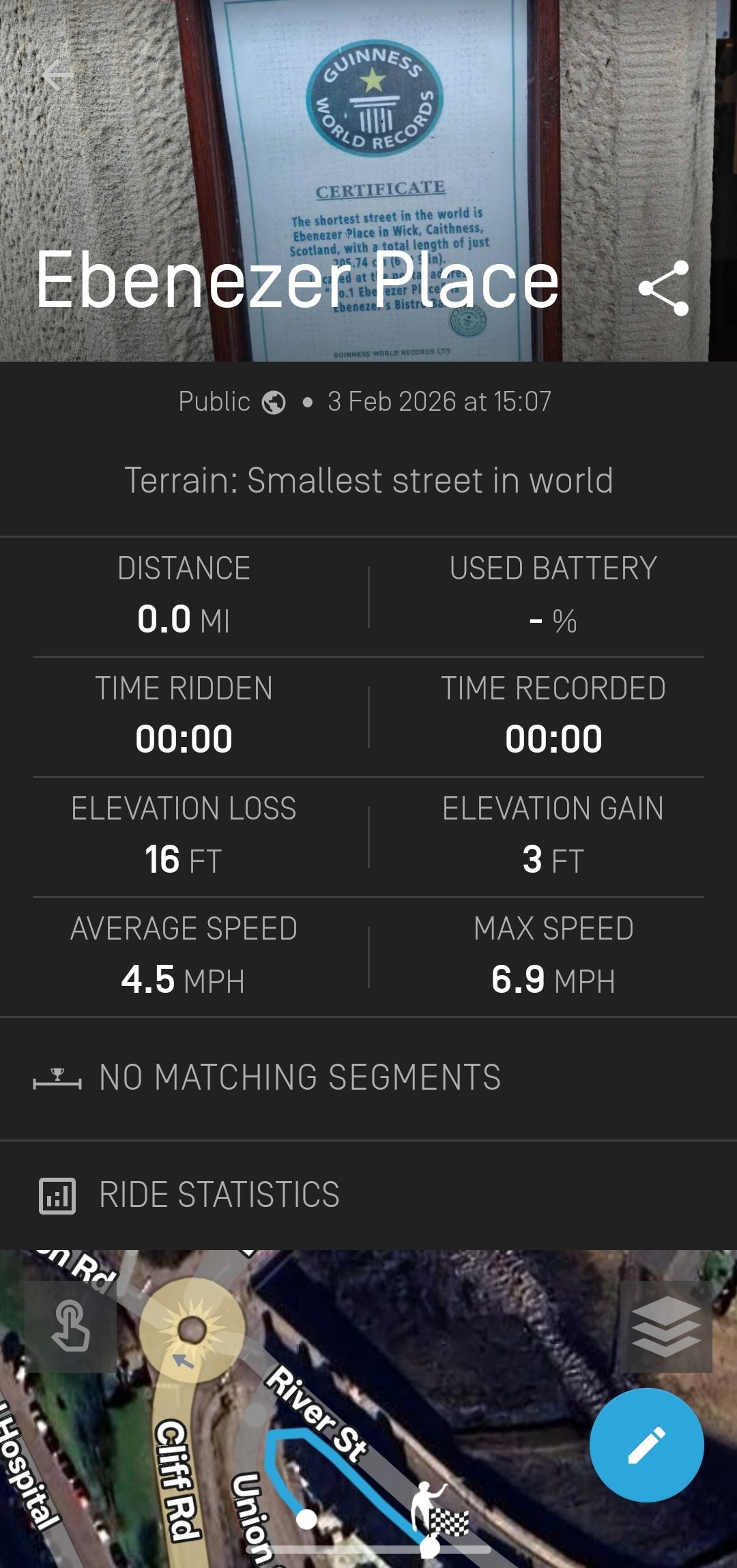

I also seem to be the first that's recorded a float at John O'Groats and also the shortest street in the world 😉 🤣

-

RE: Pint X - Error yellow 17 hot or cold with normal temp : How to change battery thermistor?posted in Repair

@rob-s It may be a bit of a tricky repair to pull the thermistors from the pack but if you’re up for it those should work fine on a pint-x. It’s a fairly basic 10k thermistor so not hard to find alternatives for if the one mentioned isn’t easy to get where you are.

Regarding getting inside the battery Mario did a teardown of a 3rd party battery that isn’t too dissimilar in structure that may help you in your journey.

Best of luck with the repair :)

-

RE: 63 YO new pint Xposted in General Discussion

@divouneh The pintX should be able to do 20. It's using the same voltage as the XR, which I've inched up to 23, 24 mph. However, I'm about 140-150lbs (depending on what the semester is looking like)

You should check your tire PSI and see if it's gotten a little low. Also, don't attempt going fast on windy days. Outside of your board, the biggest two things that affect speed is weight and wind resistance. (I think)

-

RE: Rusty stator repairposted in Repair

@LOAFFETTE The cable swap was mint! Looks intimidating at first but I guess if you defo have the right pinout then it’s just a case of patience and heat.

@Sirgu I went with some generic bearing grease on Amazon as I didn’t have a whole lot of time left to wait for any specialist grease for the specific application. Afaik for this use case it’s mostly about keeping water out so the thicker stuff seemed appropriate. High speed grease maybe if you wanna ensure no performance loss since normal greases increase the rolling resistance a fair bit once packed well.

-

RE: Rusty stator repairposted in Repair

@Lia said :

Also hyped to see you here <3

Aaa ... may I join the hype club by seeing @Beardonaboard here on forum! I think I bookmarked stuff off FB and Reddit when this huge XLV build first hit the scene.

@Lia what's the particular make of that dark green grease you chose for these bearings? Any deeper insight with it by past experiences?

-Overall another awesome thread! -

RE: Fun Videosposted in Wall of Stoke

While this is supposed to be 'First Impressions' video, it is as fun as the game "Find 10 similarities". (User manual is the best part!)

-

RE: Rusty stator repairposted in Repair

Damn, this is a repair that is for the history books!

Hopefully it works! This reminds me when I did my motor cable swap -

RE: Thinking of a retro "onewheel" projectposted in General Discussion

@lemur Duuuude I remember this thing. It’s on Instructables btw if you wanna trip down memory lane. Thing was sick!

https://www.instructables.com/Self-balancing-one-wheeled-electric-skateboard/