Followup to the Onewheel XS

-

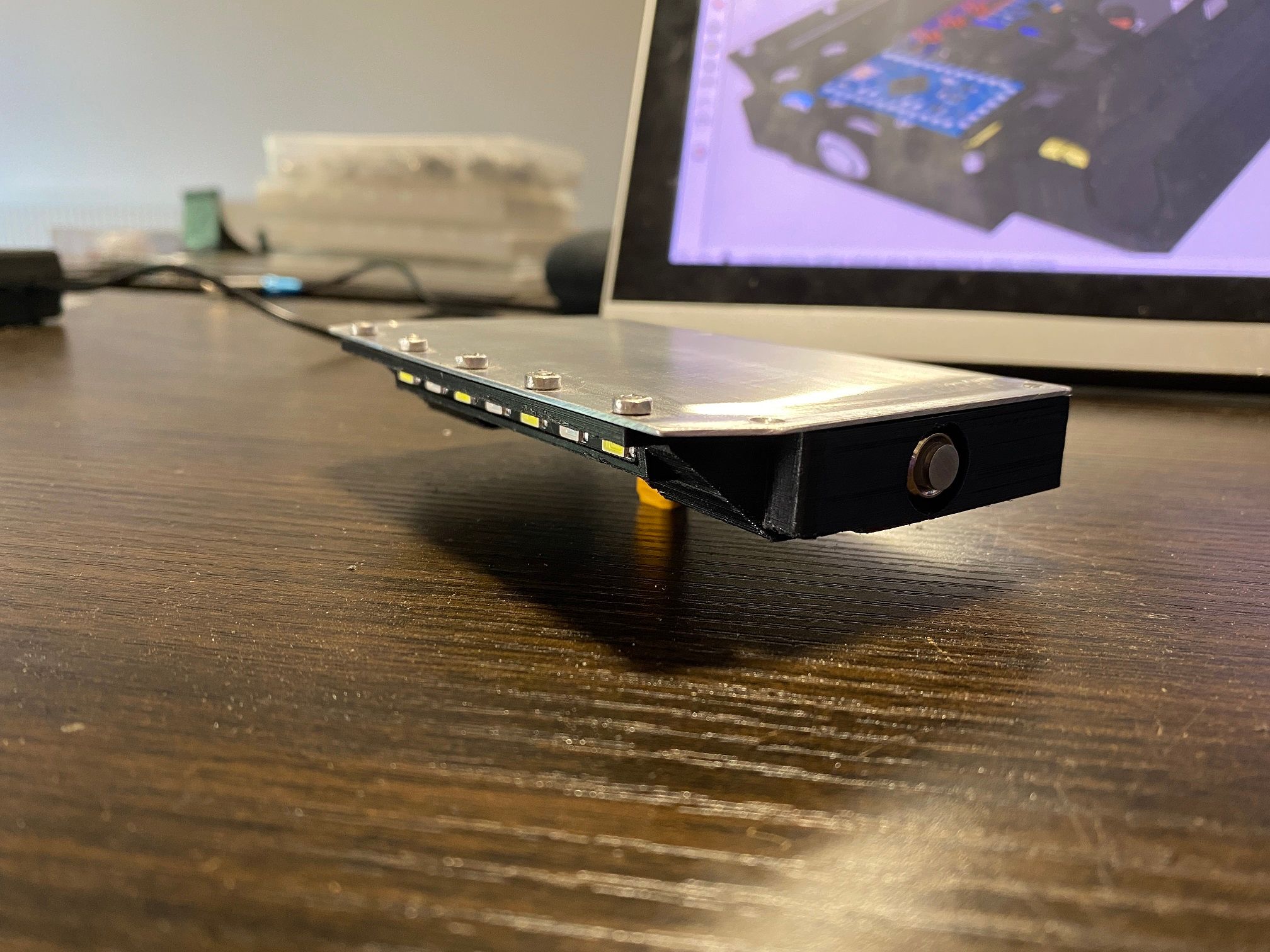

Just a quick update. LEDs are working, Arduino works and through some arcane magic I managed to resurrect the tiny power button with some

micro-surgeryspells.Haven't actually tested the charger up until this point since the port wasn't hooked up until yesterday. Here it is~

Need to adjust the flash timing on the power button a little but with the example fade code from the Arduino IDE (programmer) it works fine for demo purposes :)

Half scale XLR, half scale charger and it uses a USB C port as the power input... because there is no way I'm doing 230v AC to 16.8v DC in that space! Need to move the red and green LEDs from the charge circuit up to the indicator hole on the lid but that's for another day.

Current code that was used here.

int Wled = 5; // The PWM pin the Forward LEDs are attached to int Rled = 6; // The PWM pin the Reverse LEDs are attached to int Bled = 9; // The PWM pin the Power Button LED is attached to int Wbrightness = 240; // how bright the Forward LEDs are int Rbrightness = 255; // how bright the Reverse LEDs are int Bbrightness = 0; // how bright the Power Button LED is int fadeAmount = 5; // how many points to fade the LEDs by // the setup routine runs once when you press reset: void setup() { // declare pin 5, 6 and 9 to be an output: pinMode(Wled, OUTPUT); pinMode(Rled, OUTPUT); pinMode(Bled, OUTPUT); } // the loop routine runs over and over again forever: void loop() { // set the brightness of the pins: analogWrite(Wled, Wbrightness); analogWrite(Rled, Rbrightness); analogWrite(Bled, Bbrightness); // change the brightness for next time through the loop: Bbrightness = Bbrightness + fadeAmount; // reverse the direction of the fading at the ends of the fade: if (Bbrightness <= 0 || Bbrightness >= 255) { fadeAmount = -fadeAmount; } // wait for 30 milliseconds to see the dimming effect delay(30); }Nothing yet for detecting rotation direction, swapping the LEDs from forward to reverse or anything else really, just enough to get it working.

-

@lia Down to the charger block, the attention to detail is masterful.

-

@biell Couldn't resist, thinking of doing the Deep Shack stand too but that'll require me to learn steam bending and find a good way to do it ;)

I have an initial version of the charger before I redid the design meaning there's a little paperweight laying around that is too nice to throw away with the rest of the prototypes. Unsure if I should put together some of the better prototypes and give them away or something.

-

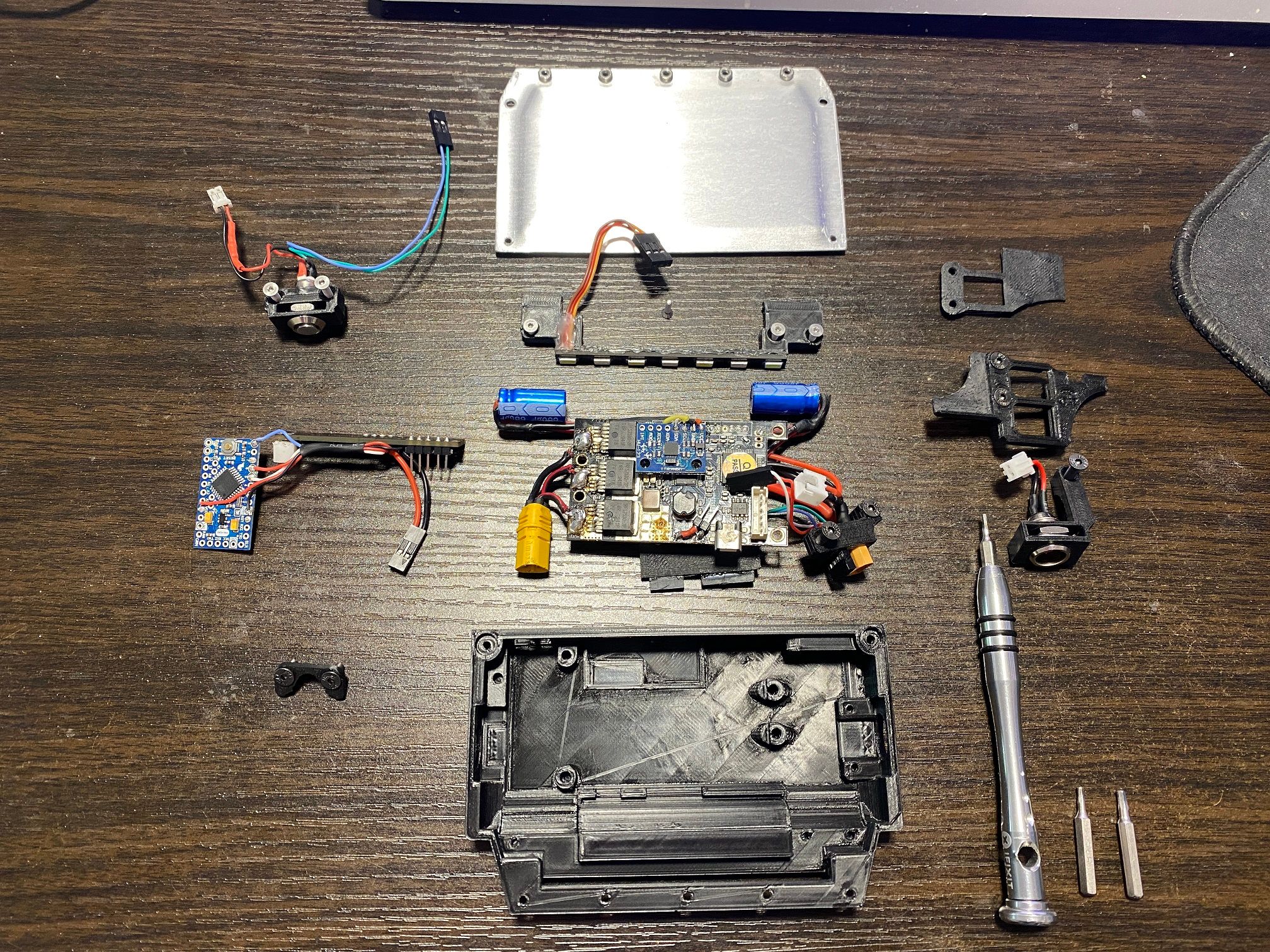

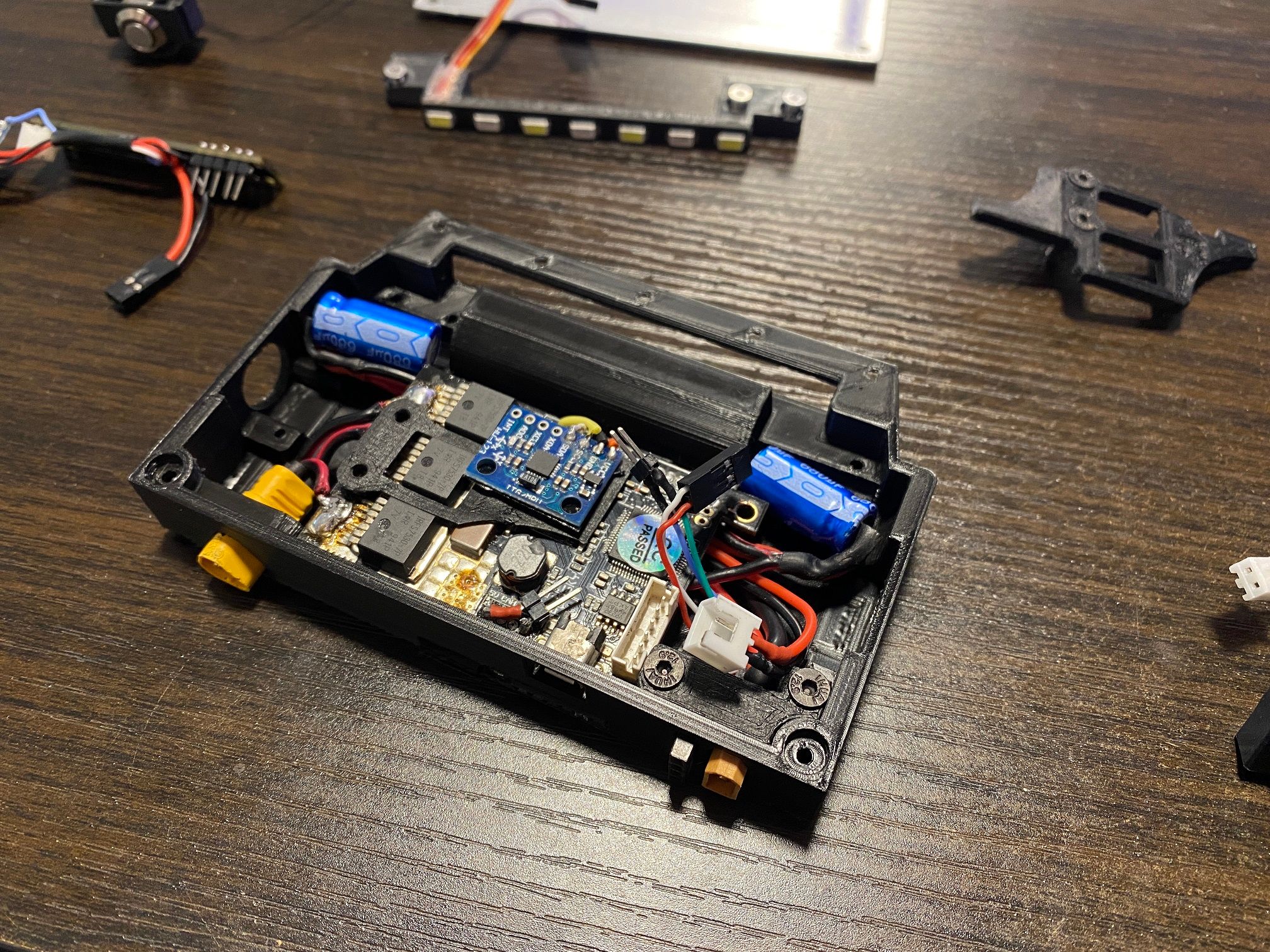

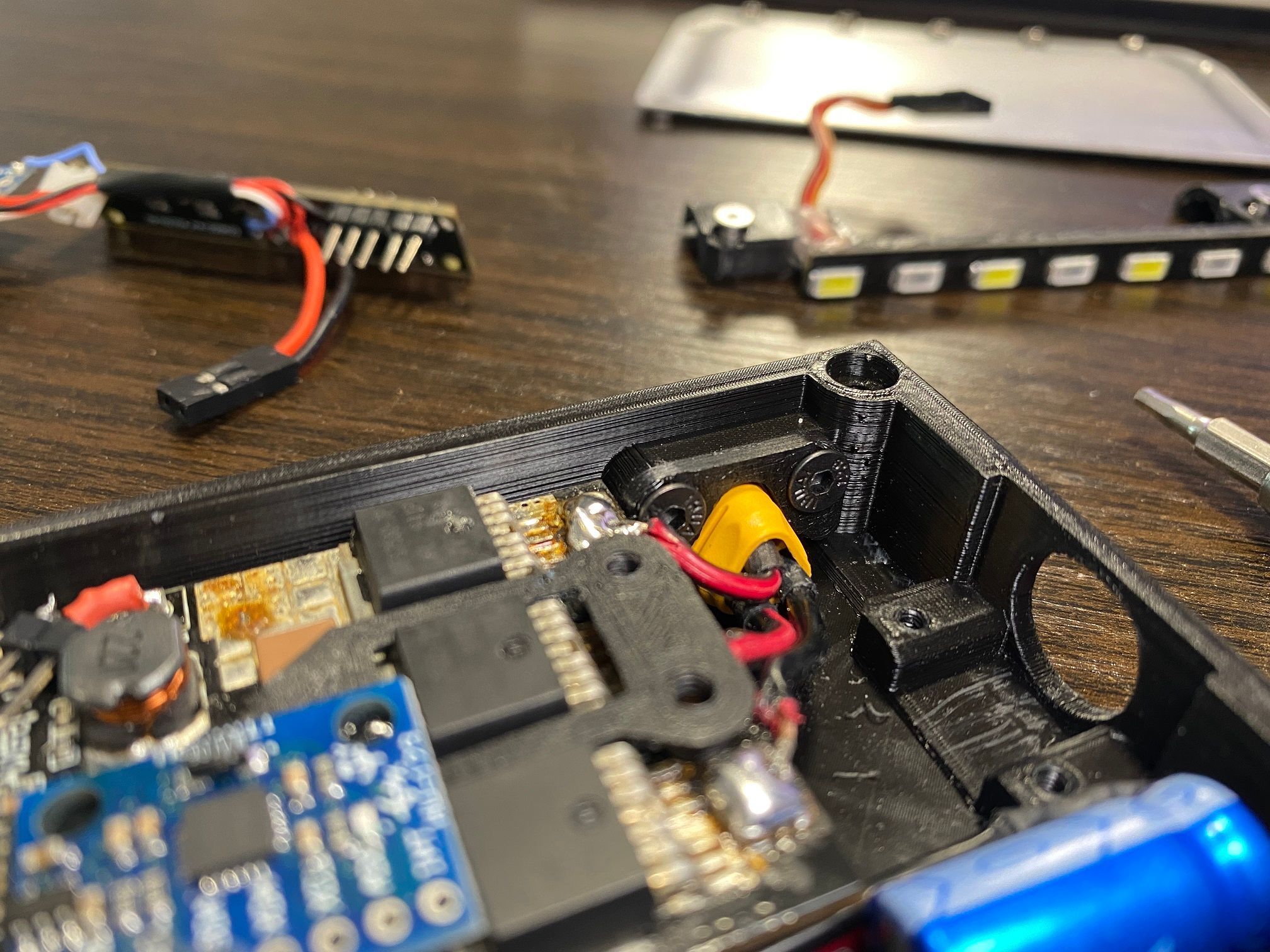

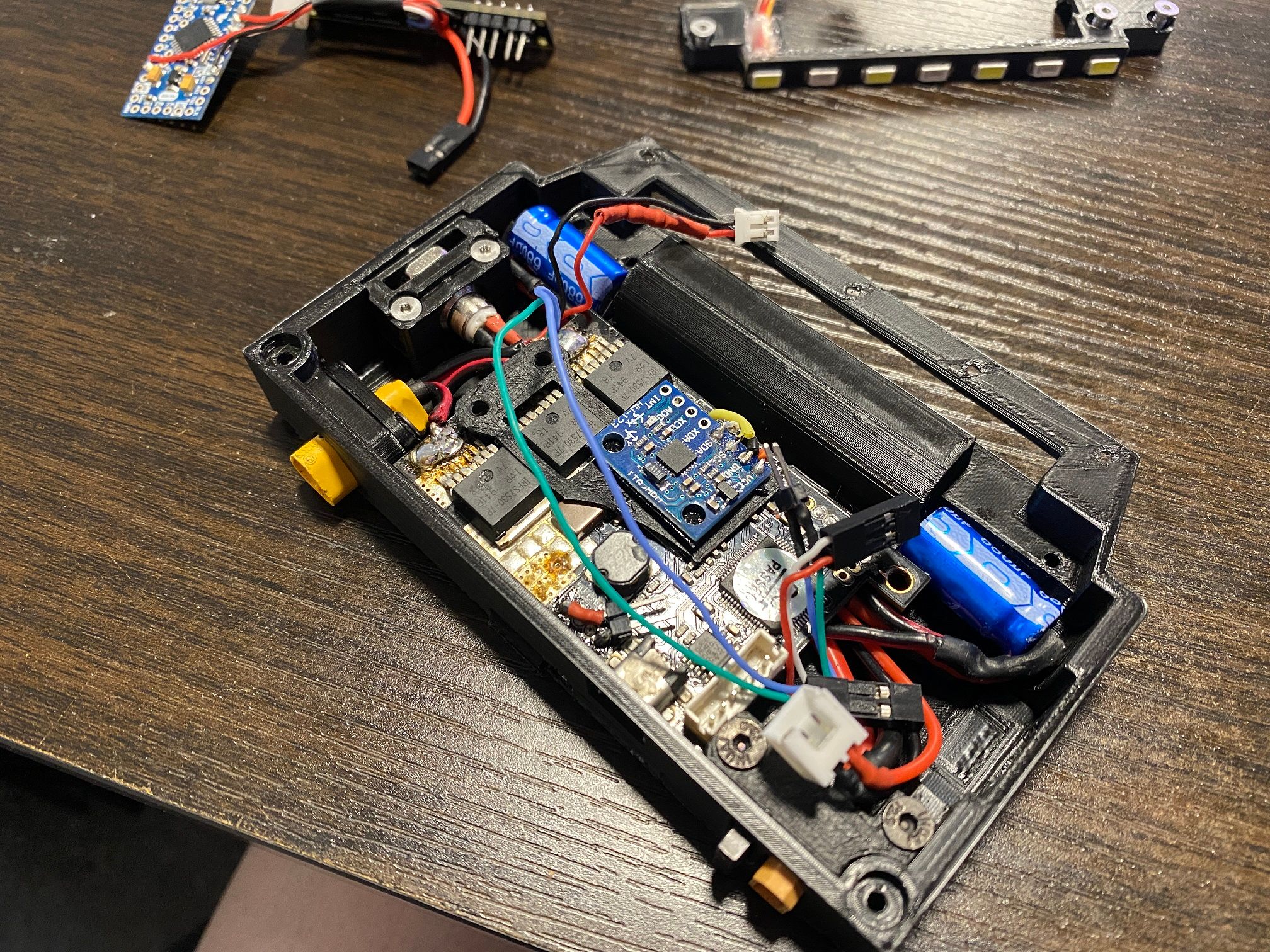

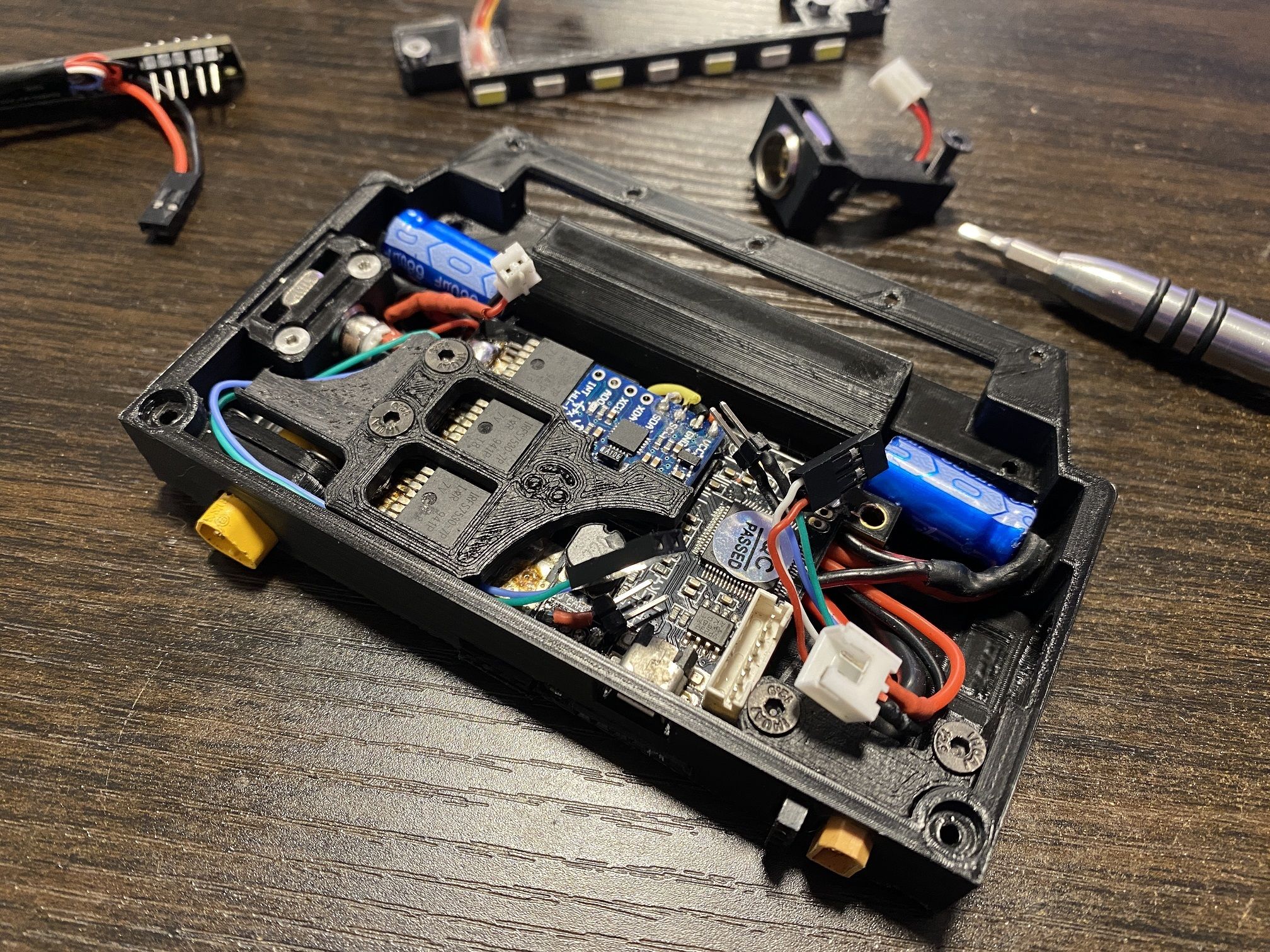

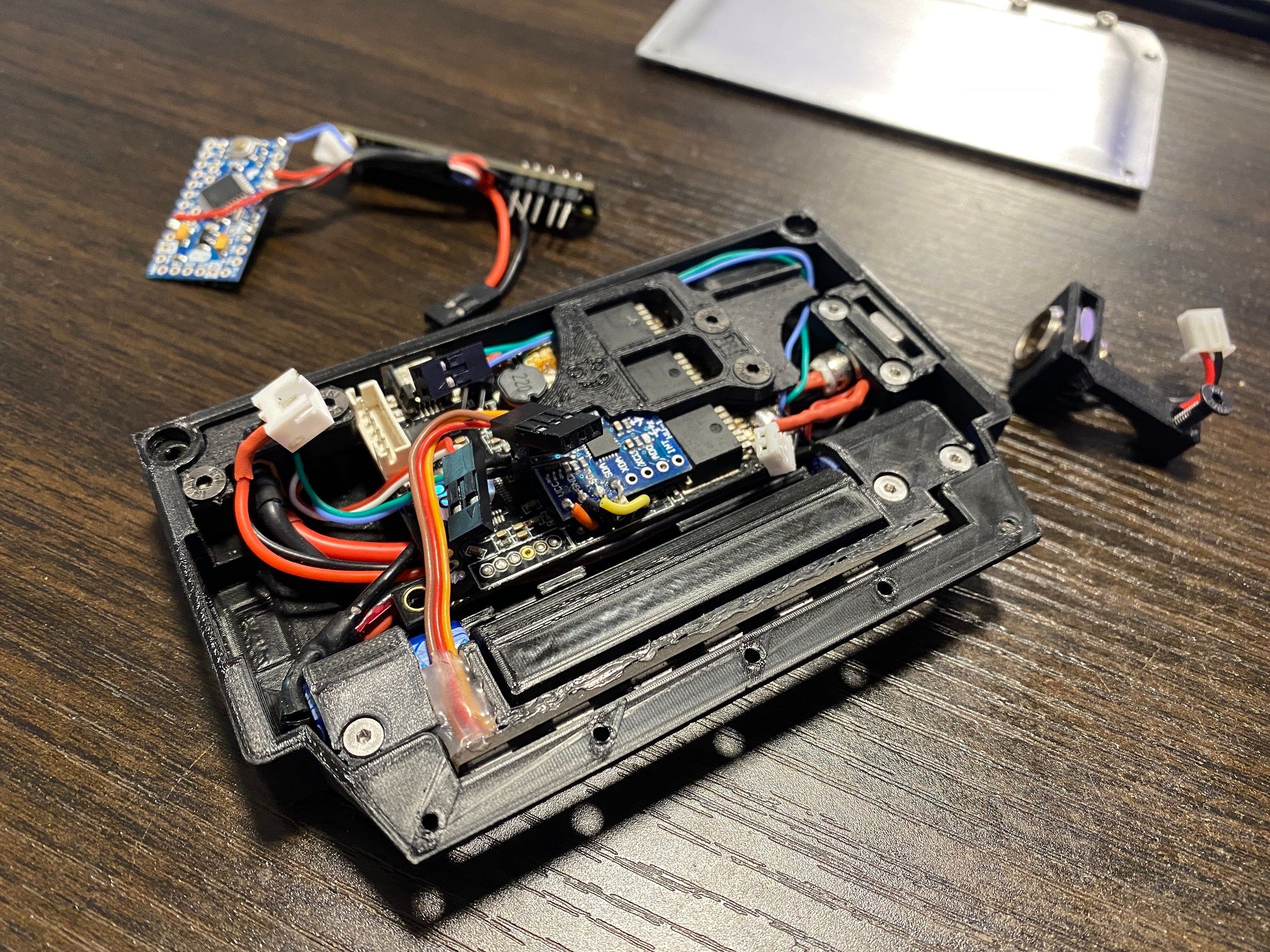

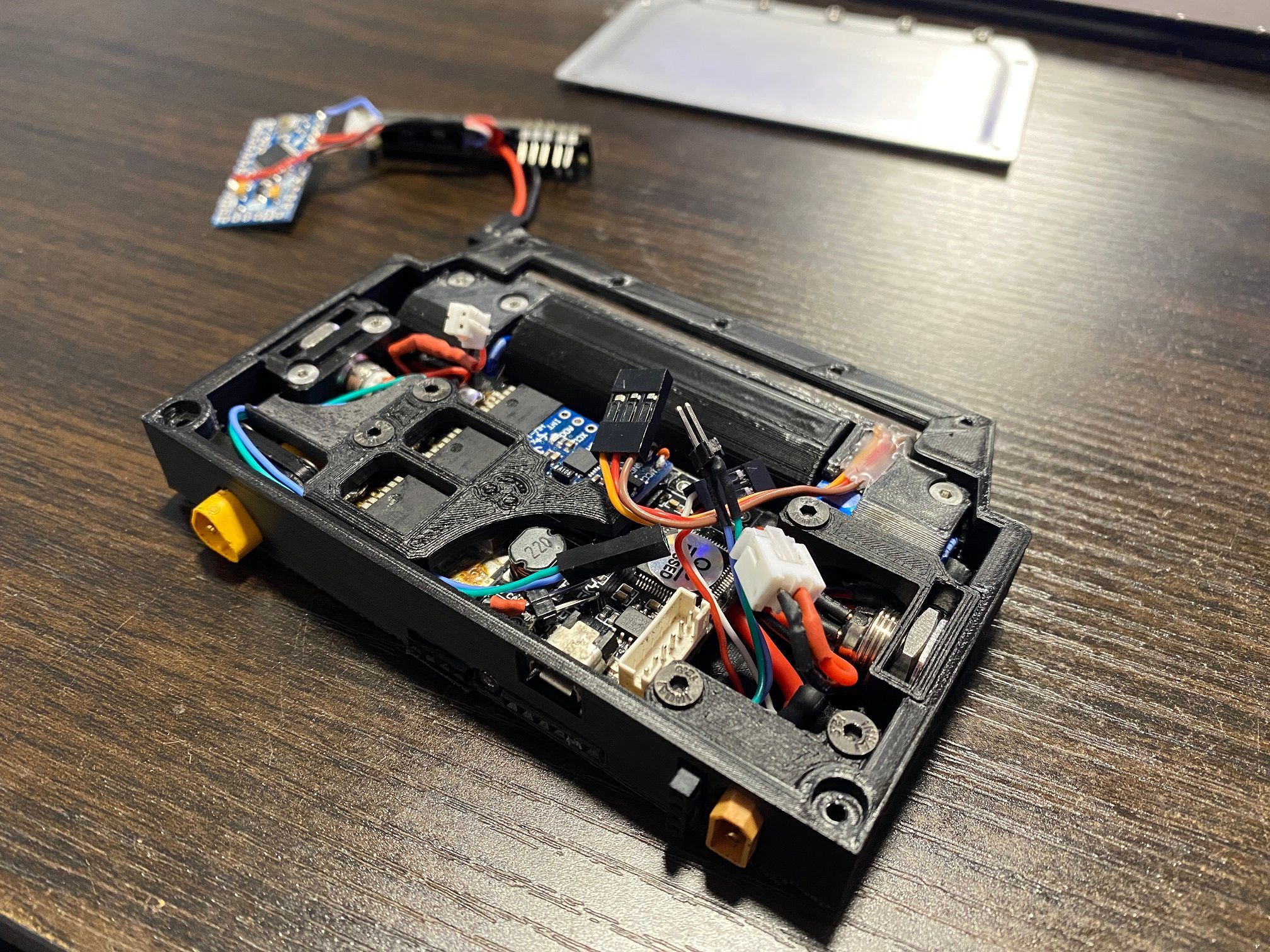

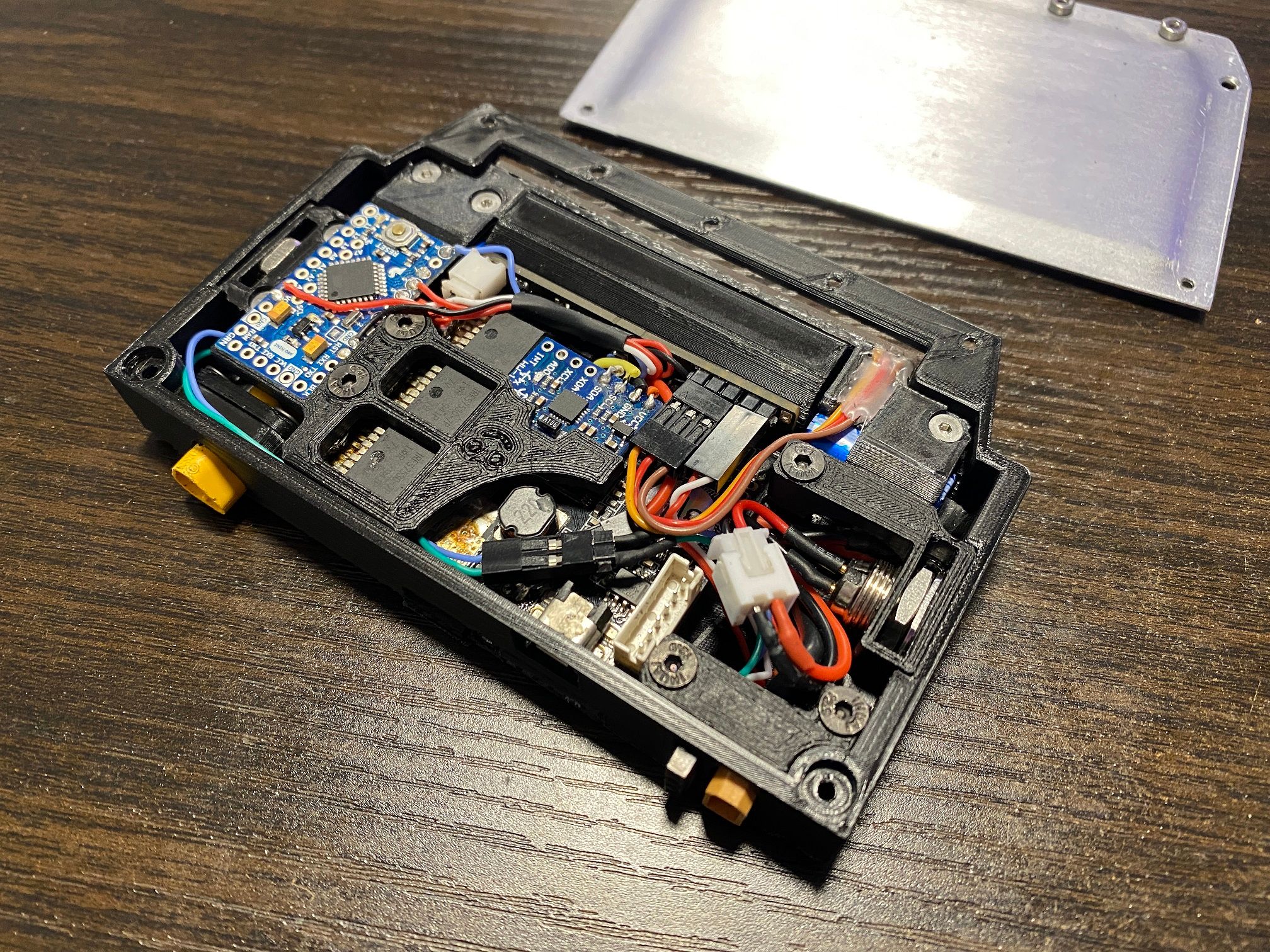

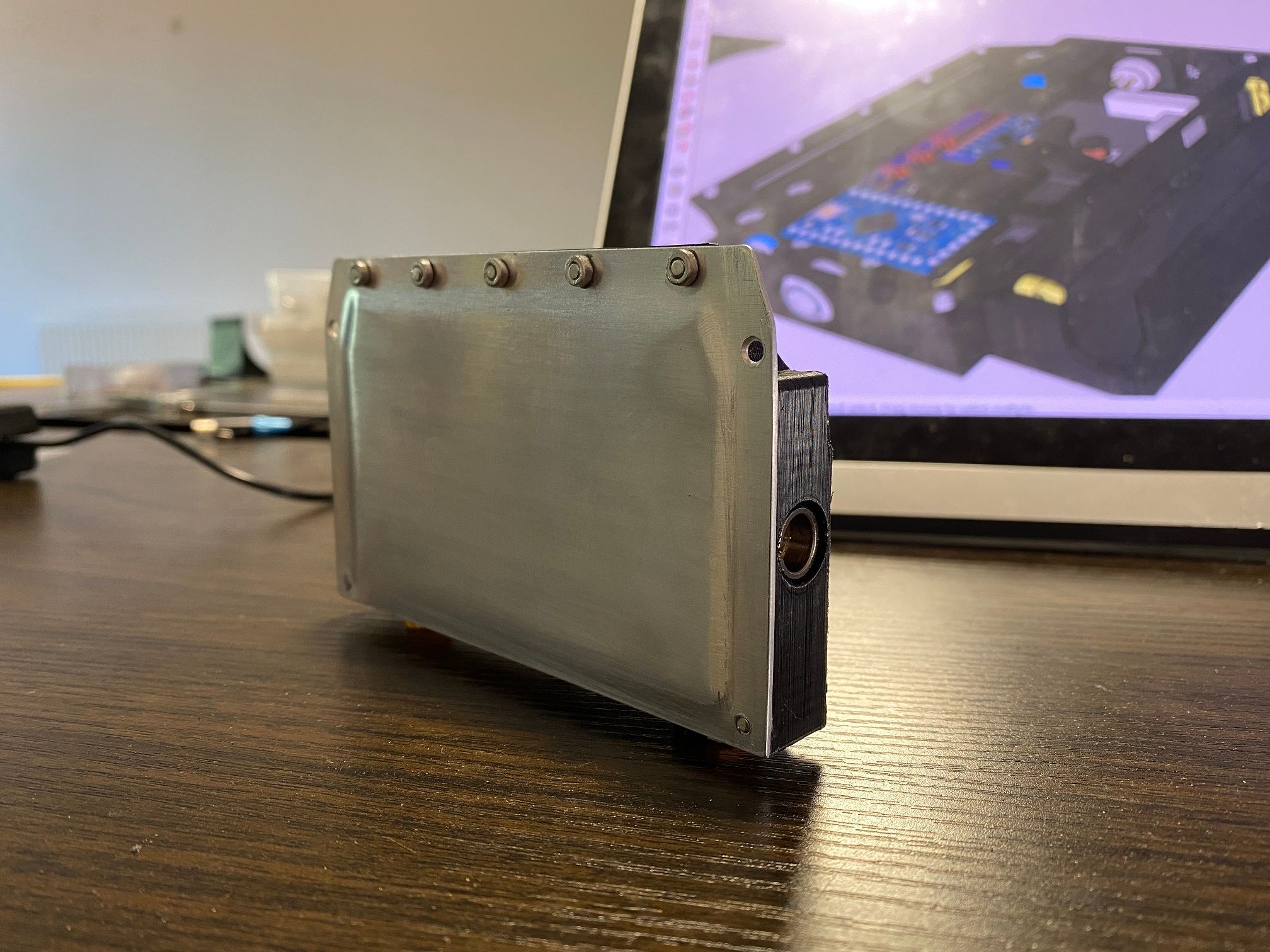

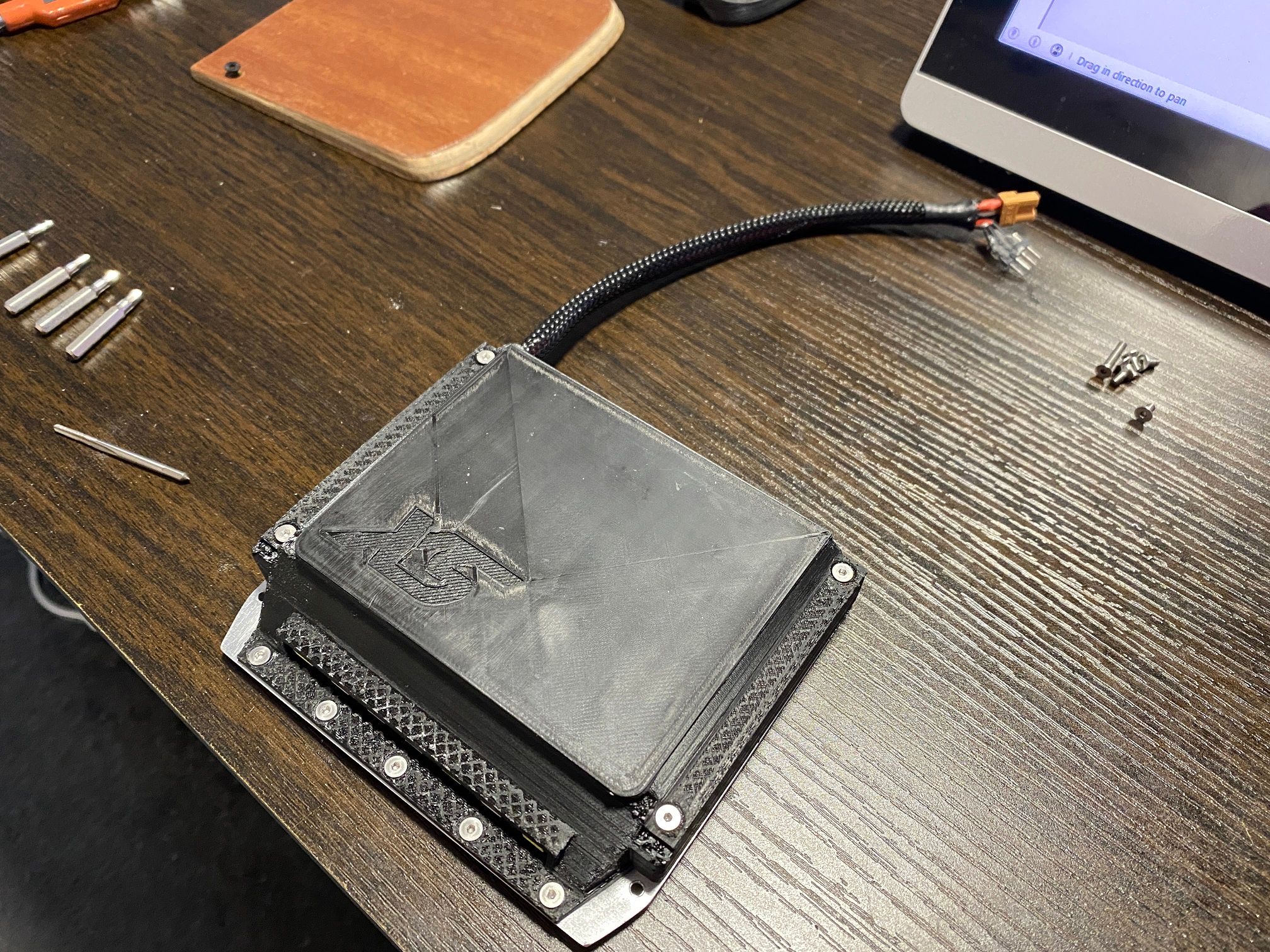

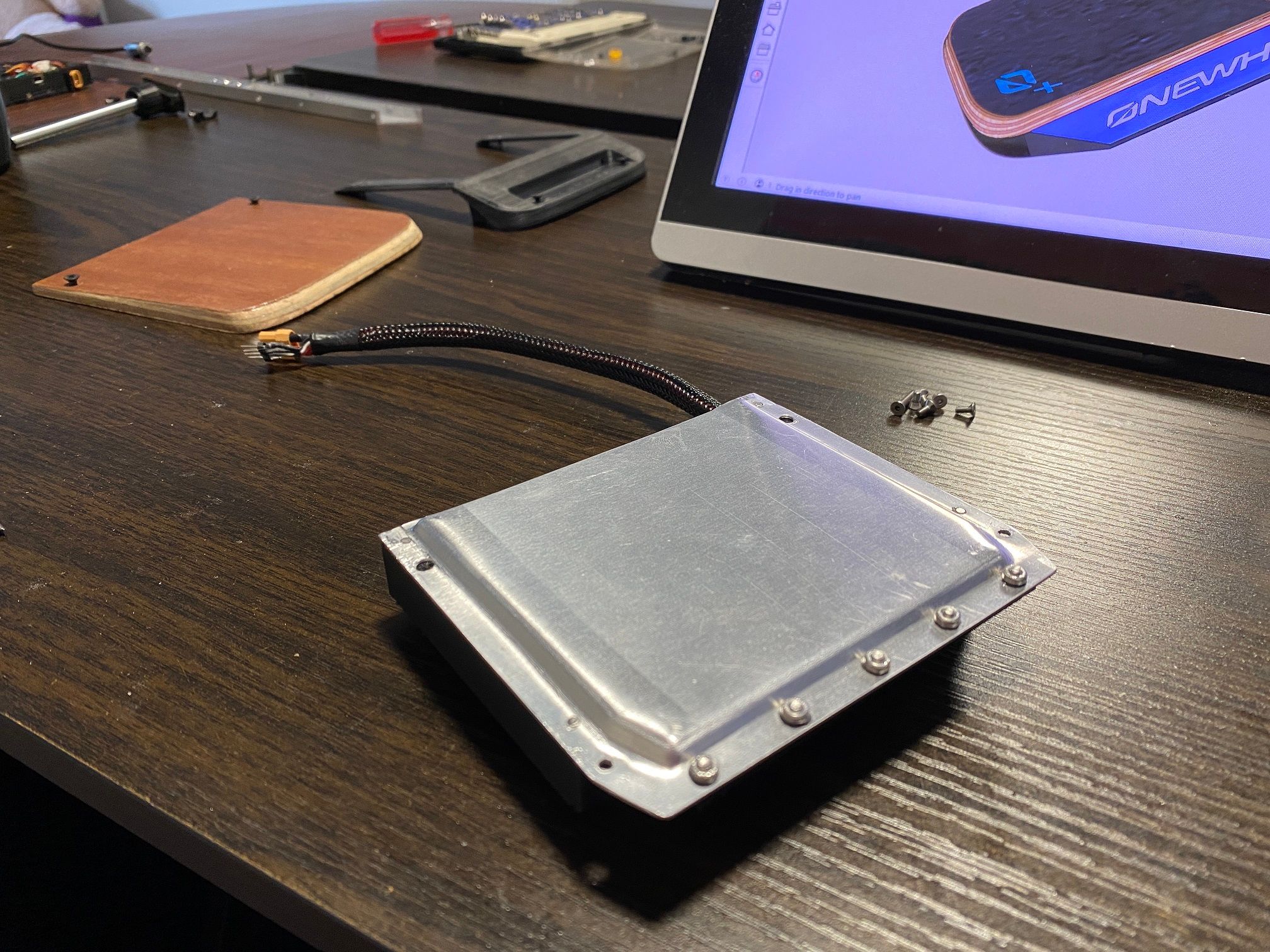

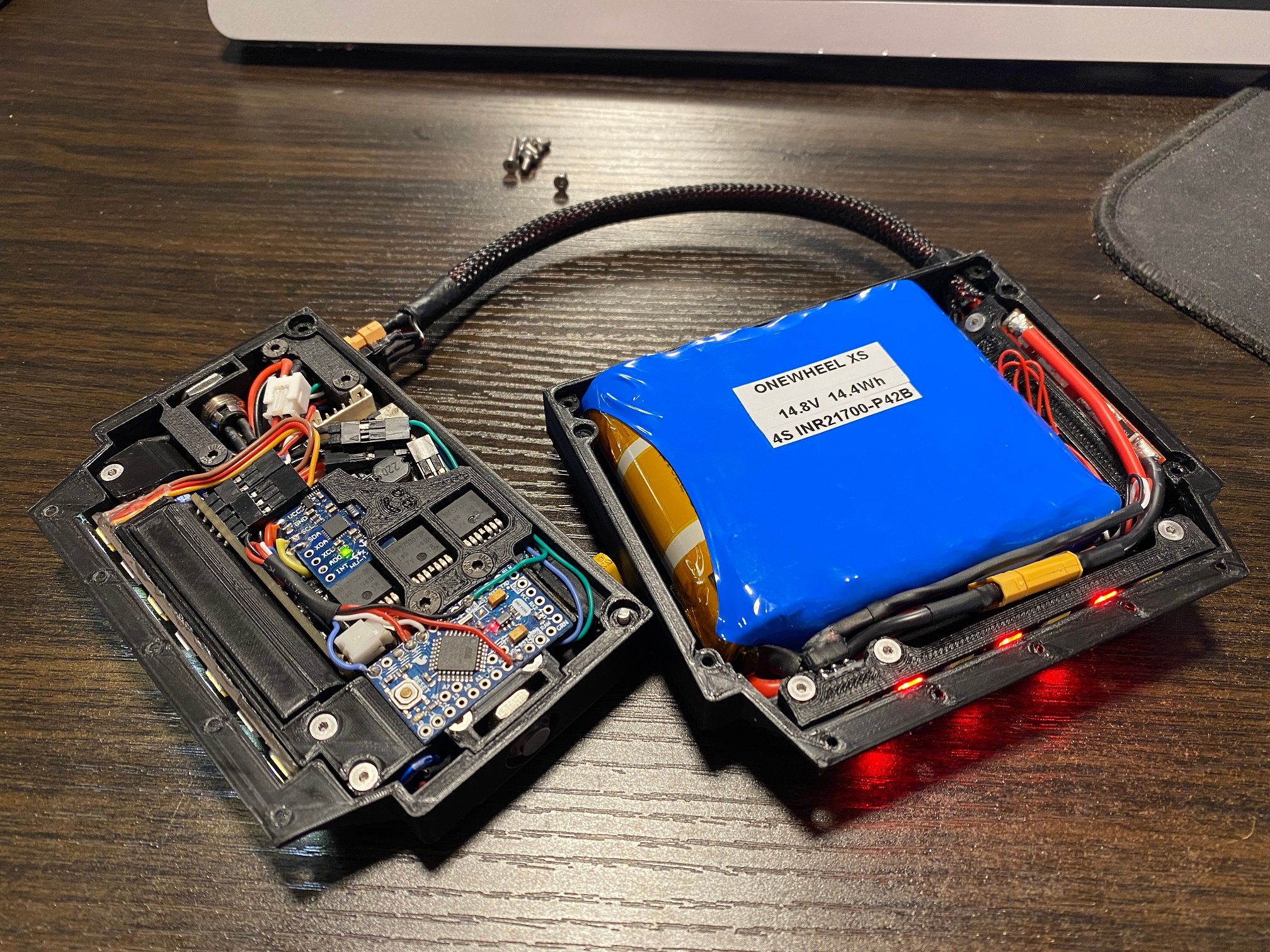

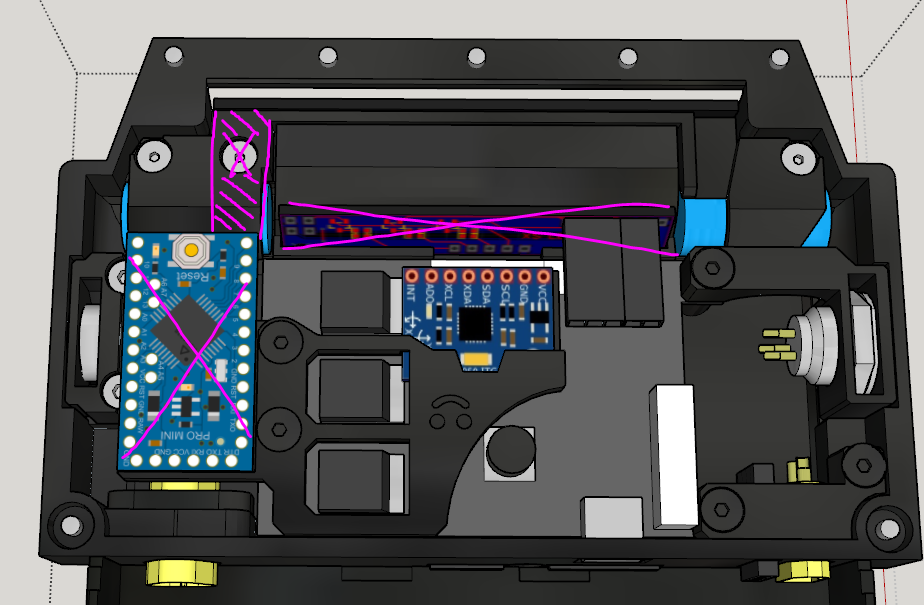

Assembled the new controller housing. Now on V12 and decided to show how it all goes together just to emphasise how dense this is. At some point I'd love to have these printed on a resin printer so the layer lines are less noticeable and the details come out cleaner. Too expensive right now though so at worst I might see if I can pay someone to print some parts on theirs.

Below are all the parts of the XS controller. Some pre-assembled into their modules like the charge port and power button.

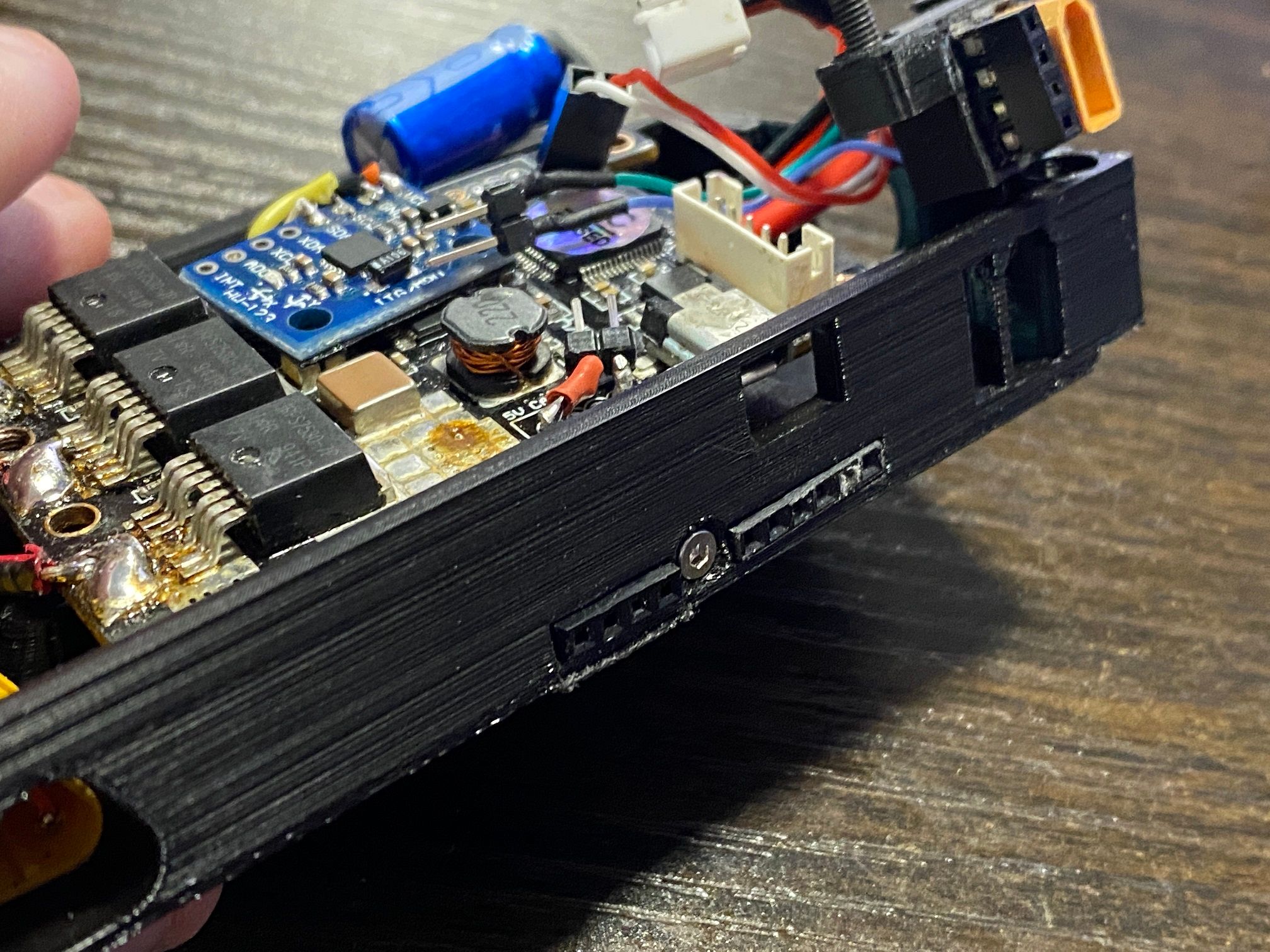

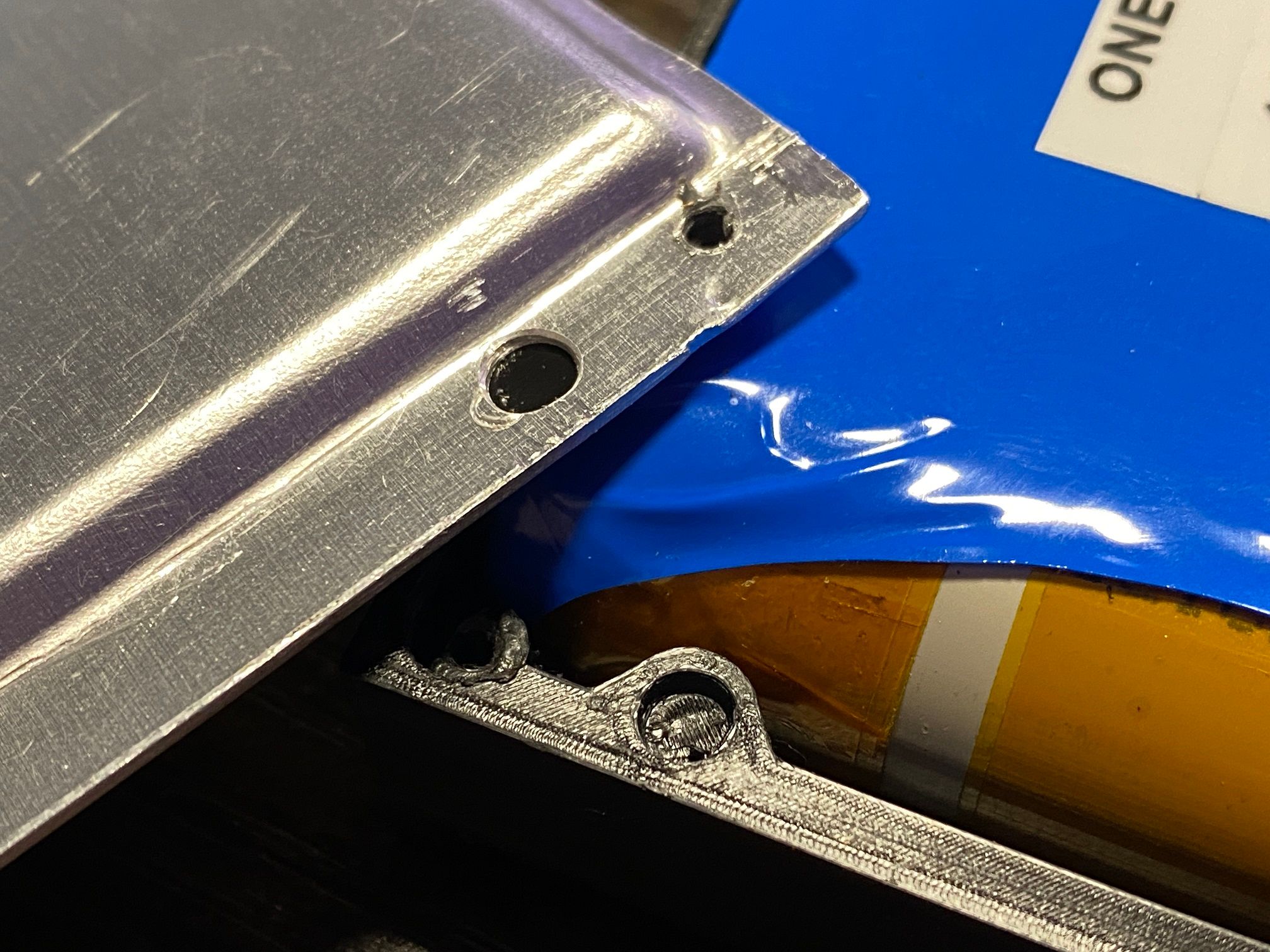

First step is to mount the FSESC and get the footpad/motor sensor wires aligned then use the m2 screw to pull them through the holes and secured to the case. Capacitors will seat in 2 cradles either side of the handle cavity while the motor connector slots into the triangular hole.

Best to slot the lower IMU mount in between the FSESC and IMU to keep it mostly aligned. Also a good time to secure the power ports which will also hold the FSESC in place on the lower right tab.

Secure the motor connector with the small bracket that traps it in the opening.

Next the power button needs mounting.

Route the blue and green wires from the power button around the edge then secure the upper IMU mount in place. The IMU is now secure while also holding the FSESC down and stopping the blue/green wires from the power button for moving out of it's desired route.

LED bar can be mounted which will also secure the capacitors in place.

Charge port can be mounted in place which locks the capacitor wiring in place and also holds down the FSESC on the top right corner now having it secured on all 4 corners. Charge port can be connected to the FSESC module with the corresponding port.

LED driver module can be slot behind the handle cavity which press fits into a mount lower down. All connectors can now be fit onto the appropriate points.

The lid can now be secured :)

That should be the controller done. One really cool thing I noticed when testing later is the handle is warm when powered on. This is because I mounted the LED driver board right up against the handle cavity which gets warm (30-40c I guess, above ambient but not hot). Imagine if the other models had this, winter wouldn't suck so much when having to carry the board ;)

As a bonus here's the XS rolling fully by itself. No strings attached, no external power. Just me pushing it around and letting it return :)

I didn't capture it but I did miss catching it on one throw meaning the XS rammed my knee. Gonna bruise as it was going pretty fast all things considered. Total weight is 2KG so it's not just a gentle tap when it's going for you.

Left the lid off for the testing because I wanted easy access to check temps and see smoke ;) As I've not added the footpad sensors there are only 5 fail modes which'll stop it from endlessly trying to balance.

- Batt too high

- Batt too low

- Overcurrent

- Roll angle out of range

- Pitch angle out of range

With that in mind when I want to stop it balancing I just roll or pitch the nose till it stops. Balancing only resumes when the board reaches near level which if paired with the footsensors will function as expected :)

Hopefully I'll be able to record some shots tomorrow and finish a vid I was working on. The XS is meant to features in a few scenes so been trying to get to this stage in order to get those last shots.

-

2 kilograms and this 3D-printed tire keeps up good work holding grip at your carpet? Outstanding motion!

-

@lia -- Your jaw-dropping XS is certainly a rambunctious little rascal!

-

@sirgu It's doing shockingly well considering that TPU isn't very grippy. Definitely need to cast a tire from rubber instead.

Kind of amusing how if I add any sort of instability on the throw it keeps it on the return. PIDs are really basic so might explain the lack of damping.

@S-Leon Rambunctious indeed!It's definitely starting to take on a personality or an attitude.

One pic I took of it a few days ago actually reminded me of a pic you took of your Plus when showing the missing battery section. Just the un-anodised rails, pad and cavity underneath.

-

I've been holding back, got some bits done that I'm particularly proud of but wanted to wait till after releasing a video before sharing ;)

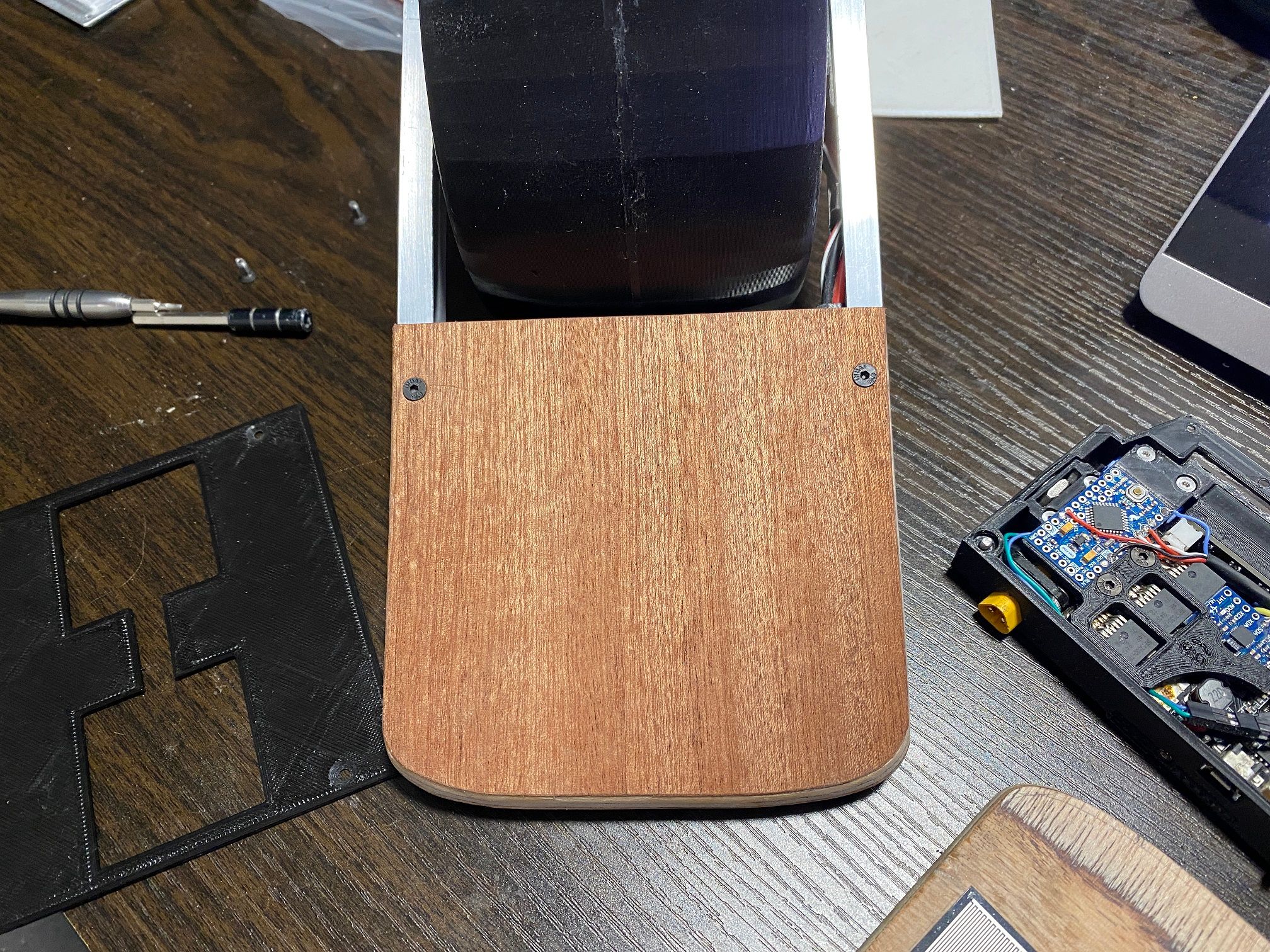

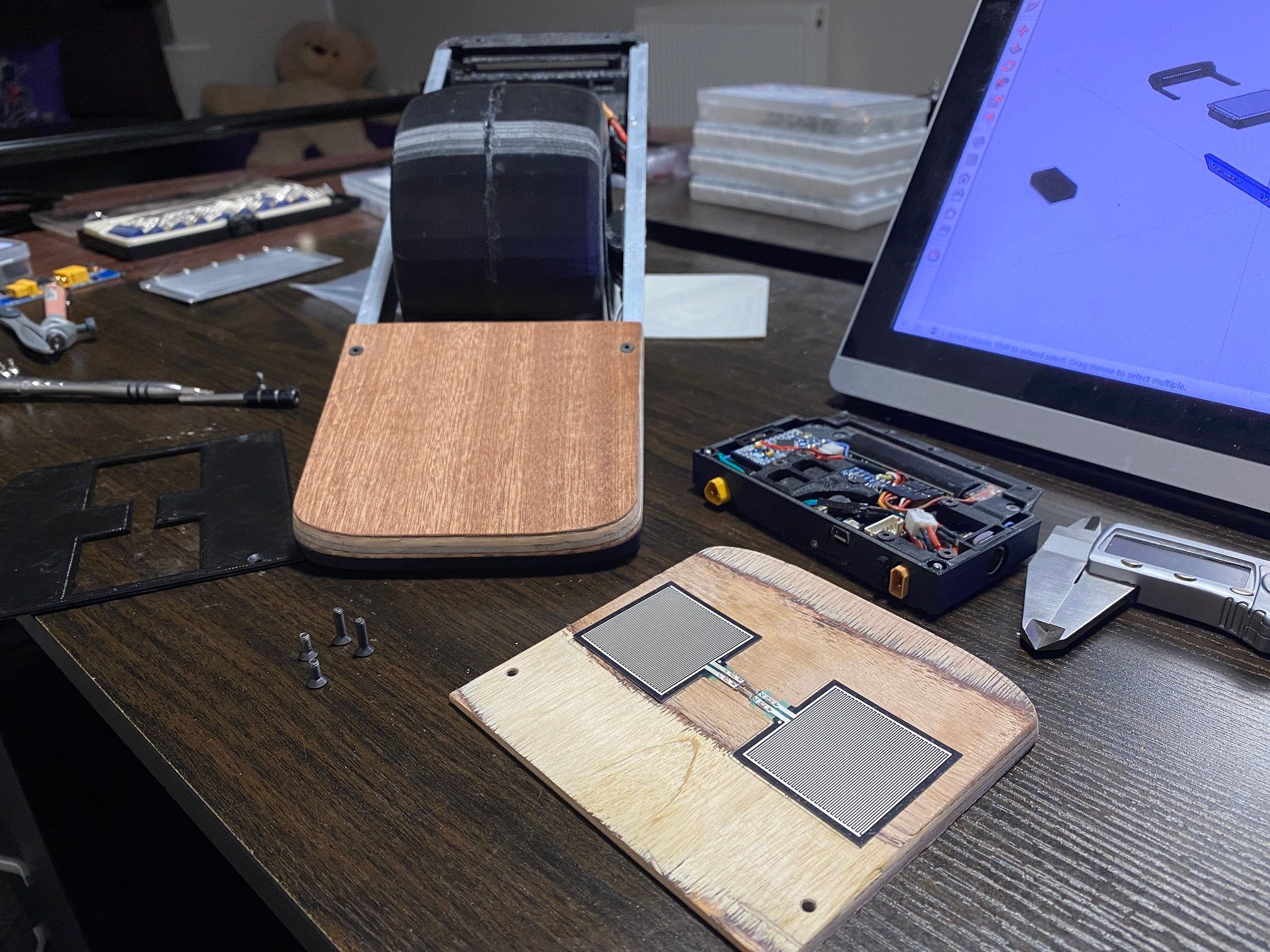

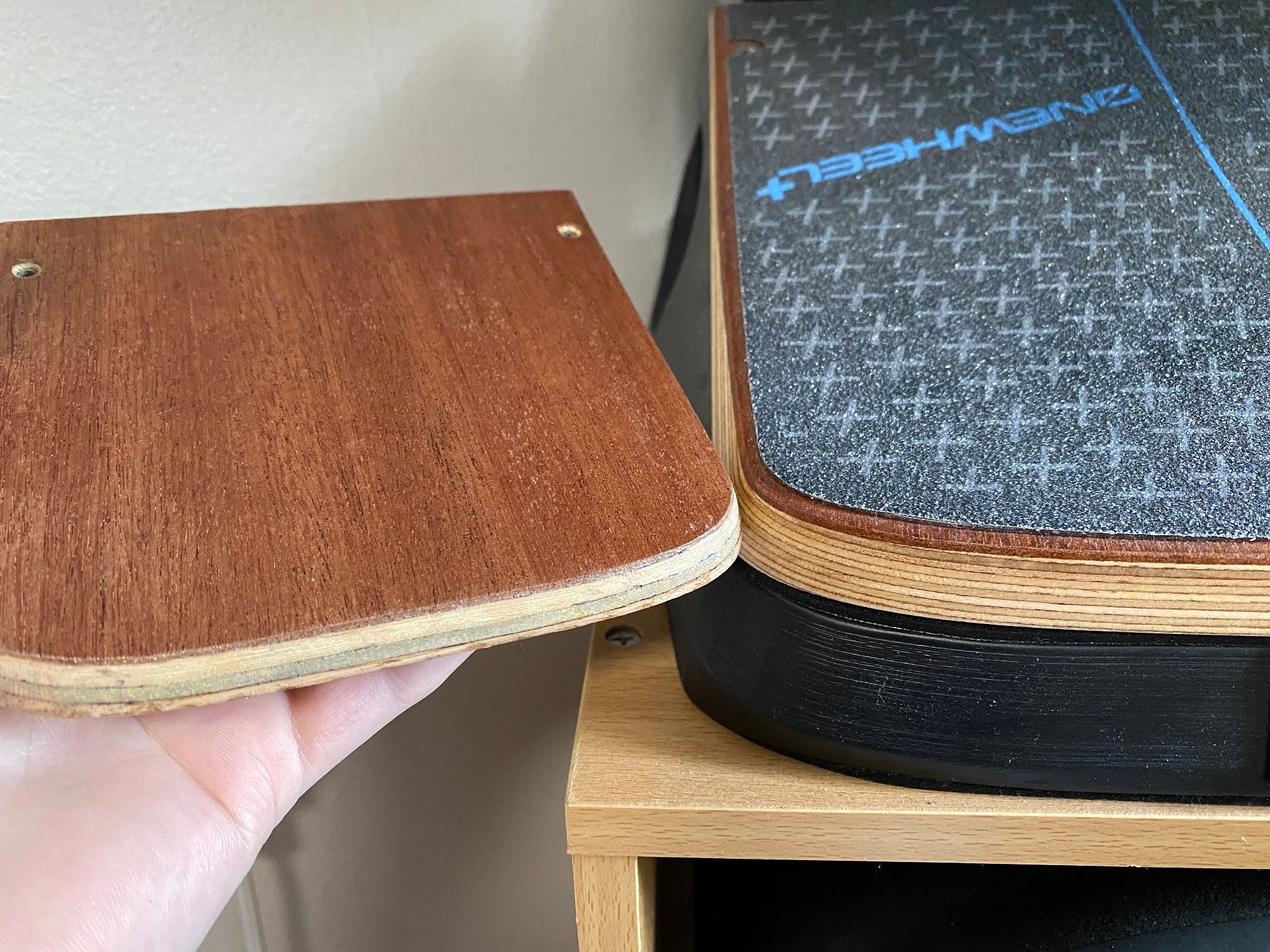

The footpads, I cannot for the life of me remember who suggested this so please feel free to remind me. Someone suggested the footpads should have a different wood layer for the top piece rather than me cheating and using a coat of varnish to artificially make the alternate top layer. It was a very good suggestion and whoever made it deserves a gold star x

However due to the size I was able to instead get away with using some veneer to achieve this and the results are great. So much better than faking it with varnish. I actually still don't know what type of wood it is though since I bought a cheap pack of assorted off-cuts and chose what looked right assuming it'd be darker after some clear coat (it was, more on that later).

Looks good so far, still needs the clear coat however I wanted to also get the front done andalso mount those little sensors.

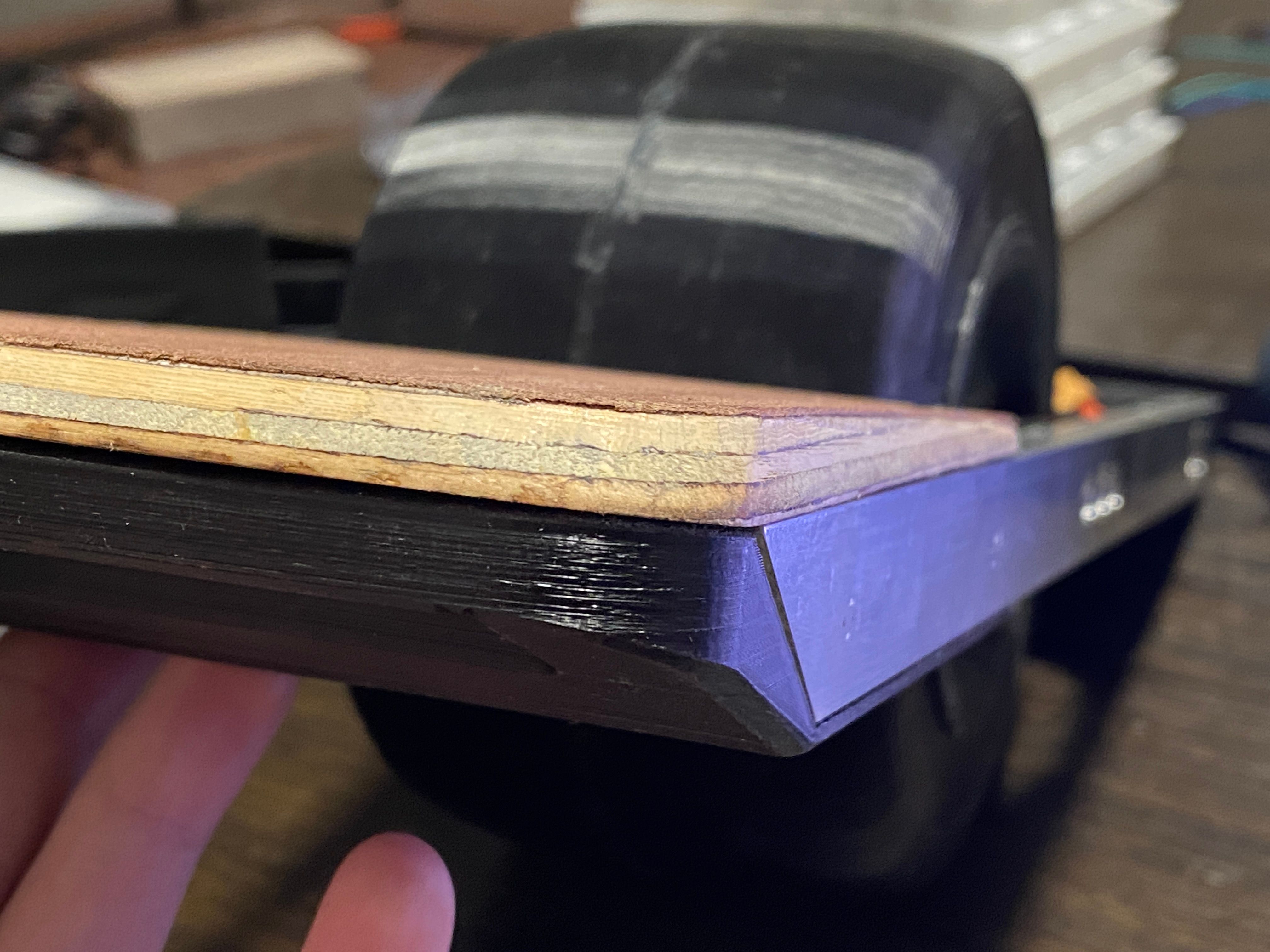

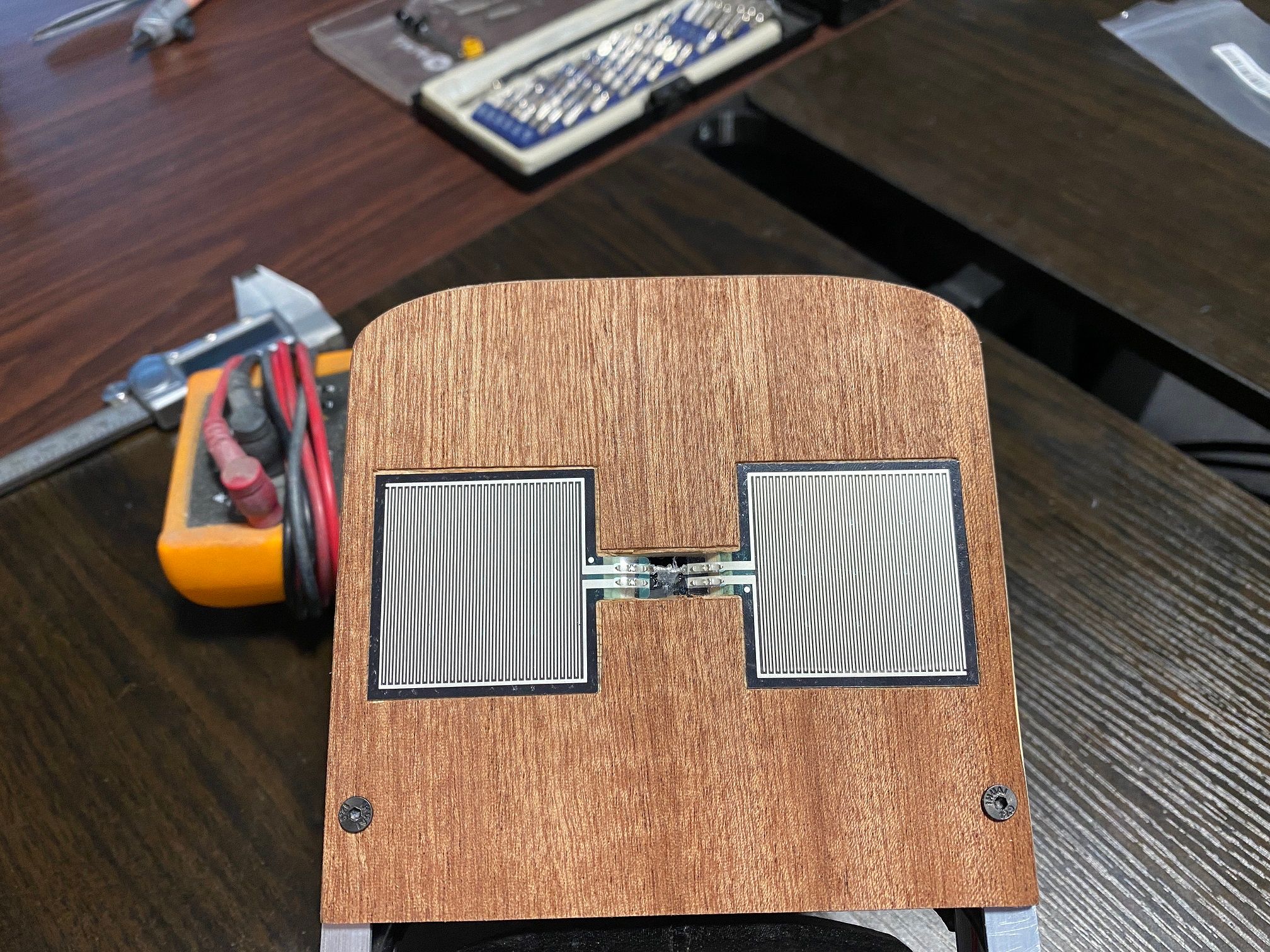

Reminiscent of the V1 sensors hat didn't occupy the entire footpad. To make sure the griptape didn't bulge because the sensors were taller than the veneer I cut out where the would sit and then placed that on the pad making the sensors barely sitting proud of the surface. Enough to function under griptape (tested with a sheet of paper) but not so that you can clearly see where the pads are.

Lastly came the clear coat. I haven't done the front pad yet but the rear came out so well I'm eager to do it.

You'd think I knew what I was doing, it's almost perfect (ignoring the ply density)

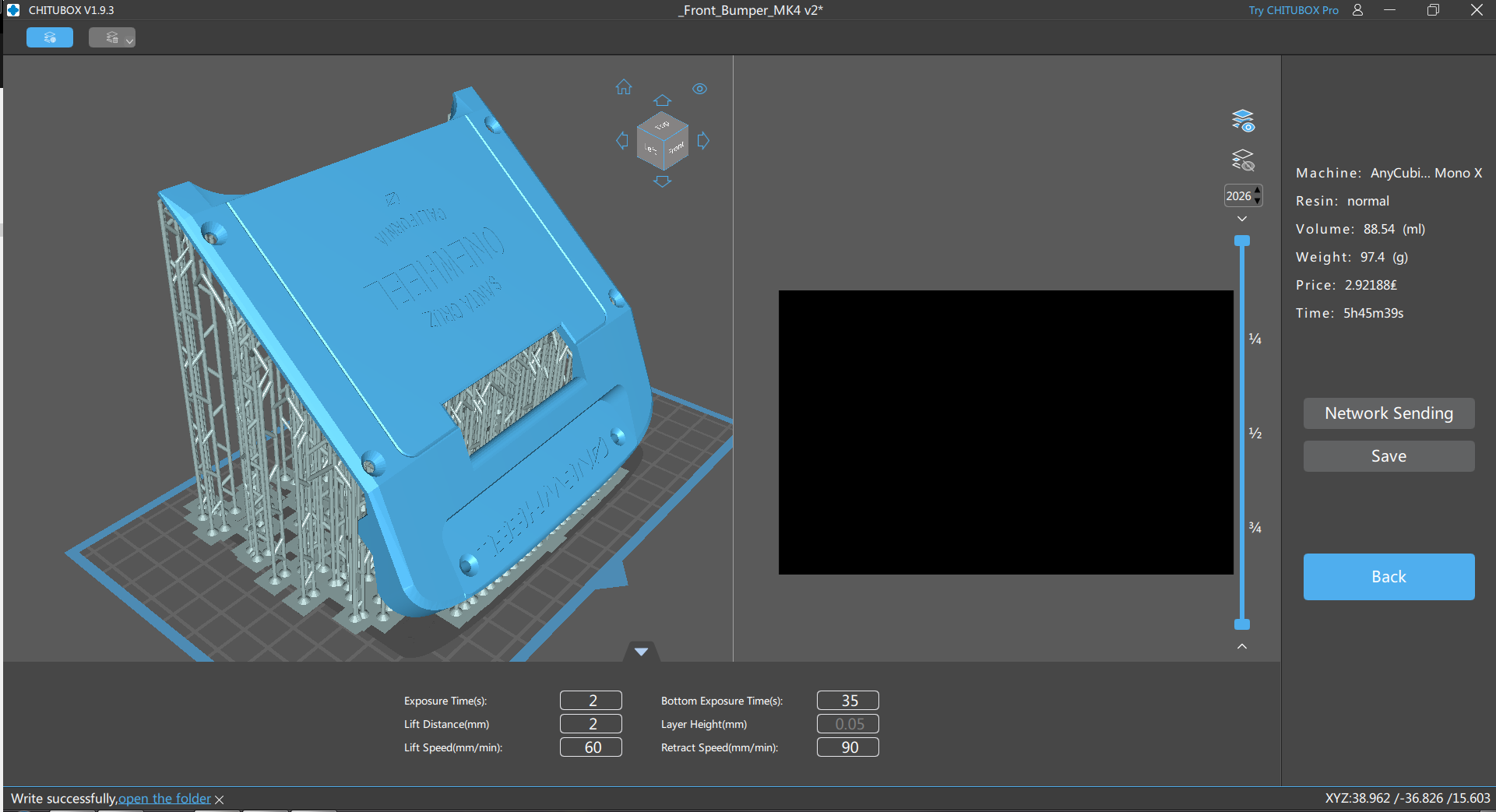

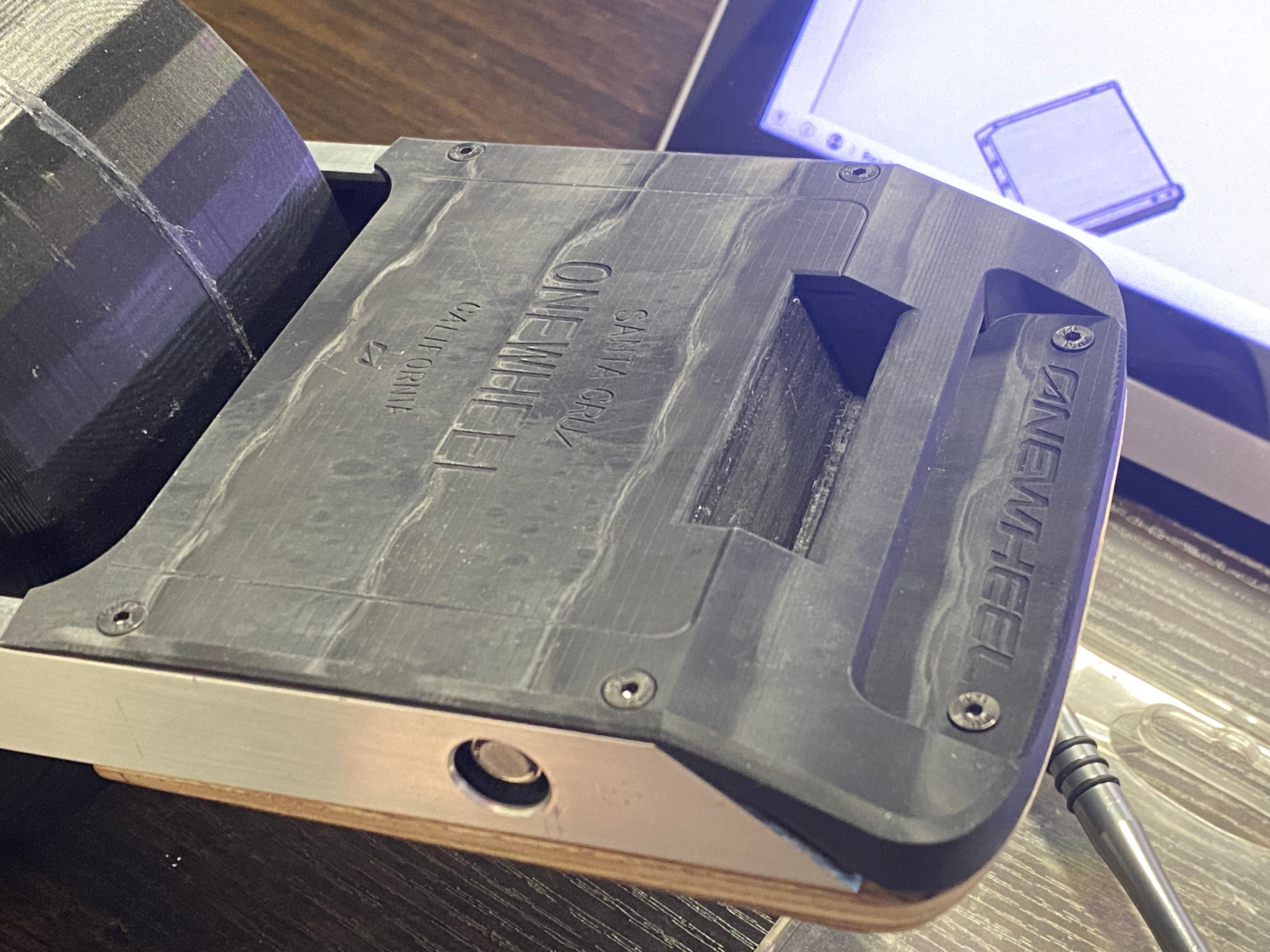

As an added bonus I redid the front bumper to remove the pillowing effect caused by the infill pattern on the last one. After a light sanding it's buttery smooth. Almost looks like it was done on a resin printer. Still want to resin print these though for the added detail retention on the lettering.

To see my playing around with it working there's a few sprinkled in clips on the video I mentioned earlier.

It's so stupidly fun to just place 2 fingers on the pads and feel it move once level. Nothing, not even a video can translate the stupid joy I get letting it roll around. I made noises I didn't know I was capable of, which thankfully will never leave these walls ;)

-

Few more updates :D

Finally gave reddit an update too, of course here is where all the best pics and info is though :)

Replaced the axle with a steel one. Had a feeling the aluminium one might bend which would probably destroy the bearings and motor. Was too scared to use my angle grinder so spent like 20 minutes with my little dremel cutting through 8mm of steel bar to get a 115mm long axle. Worth it though, look how shiney it is compared to the scuffed up oxidised aluminium one.

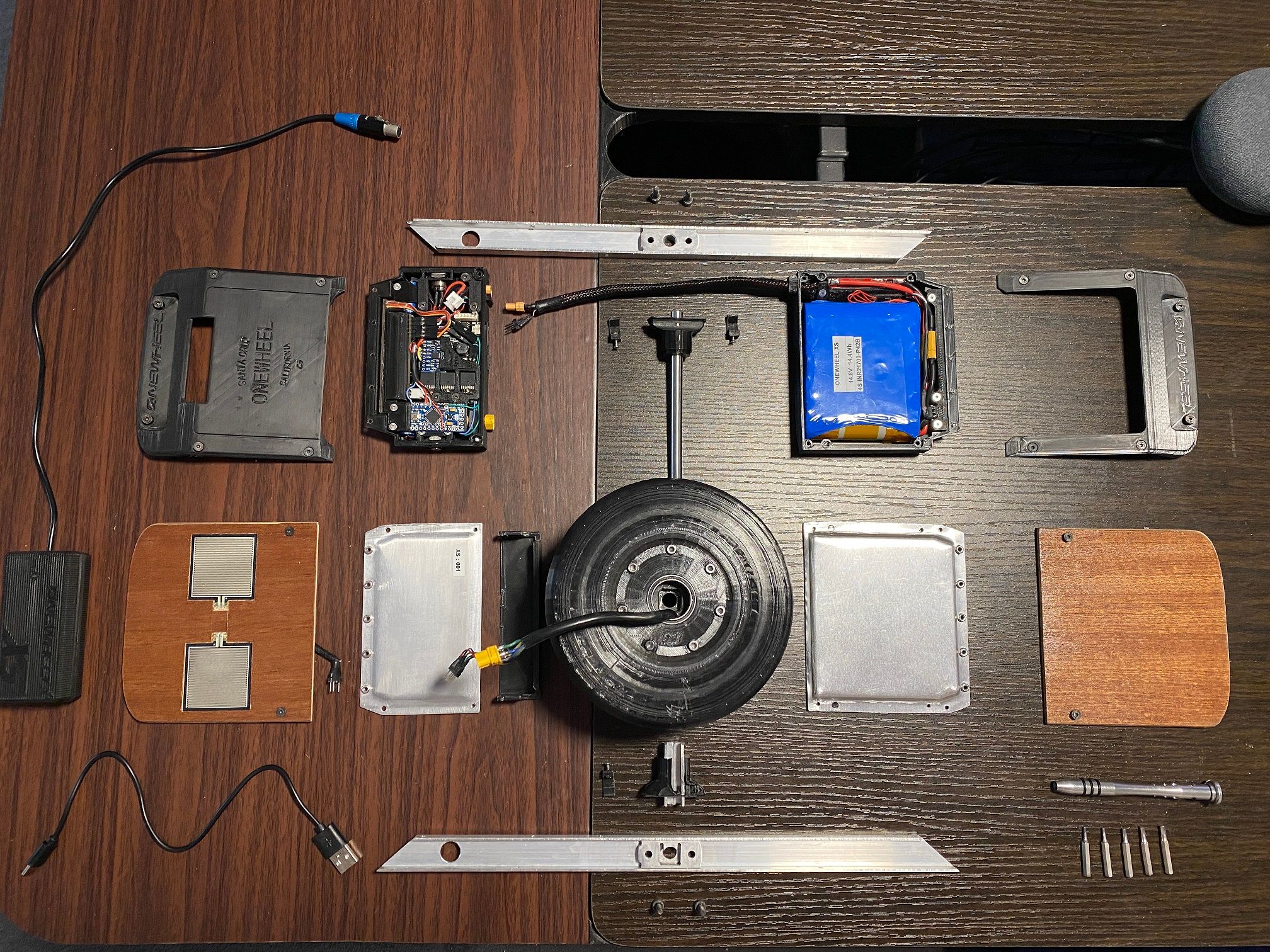

All in bits down to the major components this is what it looks like.

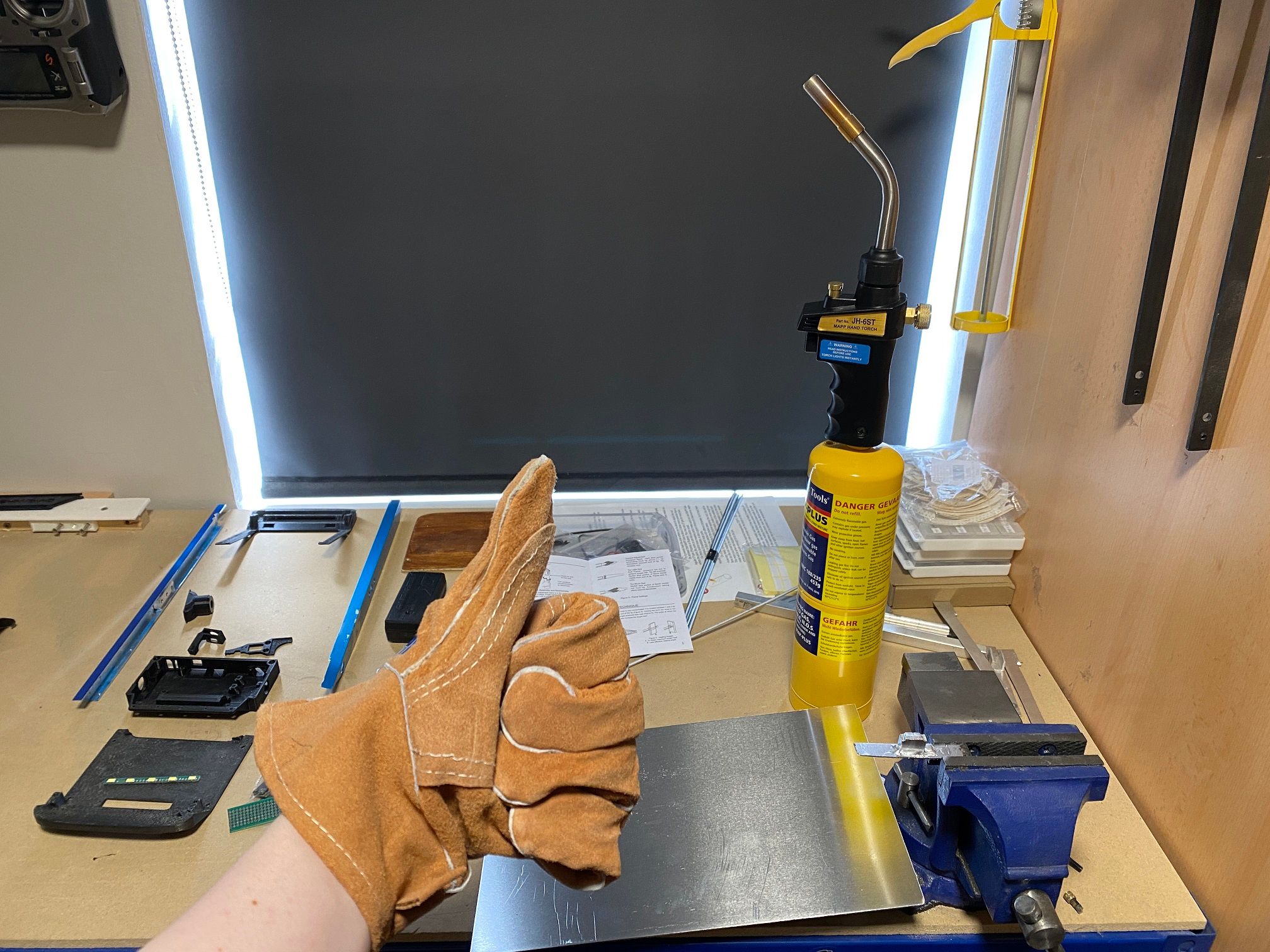

Worked up the courage to try the gas torch today with the brazing rods. These rods melt real quick and I haven't yet mastered the finer touch like I have with normal soldering so although I didn't burn myself or explode the can I'll instead JBweld the axle block to the rail. Tried to do it and it got messy D:

I wish they made smaller gloves too. These gloves are huge... like... do they come in women's sizes lol. I'll keep practising so I can continue the W-Rails.

Redid the battery housing again, this time to make the underside prettier and to add some cups to stop me long-screwing the housing with the footpad screws.

Totally replecated the same choice FM did with the battery lid because I wanted to and not because I didn't want to perfectly shorten the screws >.>

Got a nice pic of the 2 boxes plugged in next to eachother. Sadly the power button LED has died so I'll need to wait for another one of those to come from China :( Can't be too sad though when I have this eye-candy at my fingertips.

Coated the front footpad, sadly some got into the left pad somehow. I managed to remove lot of it with IPA and squeeze it out but there is now a noticeable dead-ish zone that isn't as sensitive. Woks fine but makes finger riding more difficult.

Final versions of the bumpers prior to hopefully getting them resin printed sometime look real good.

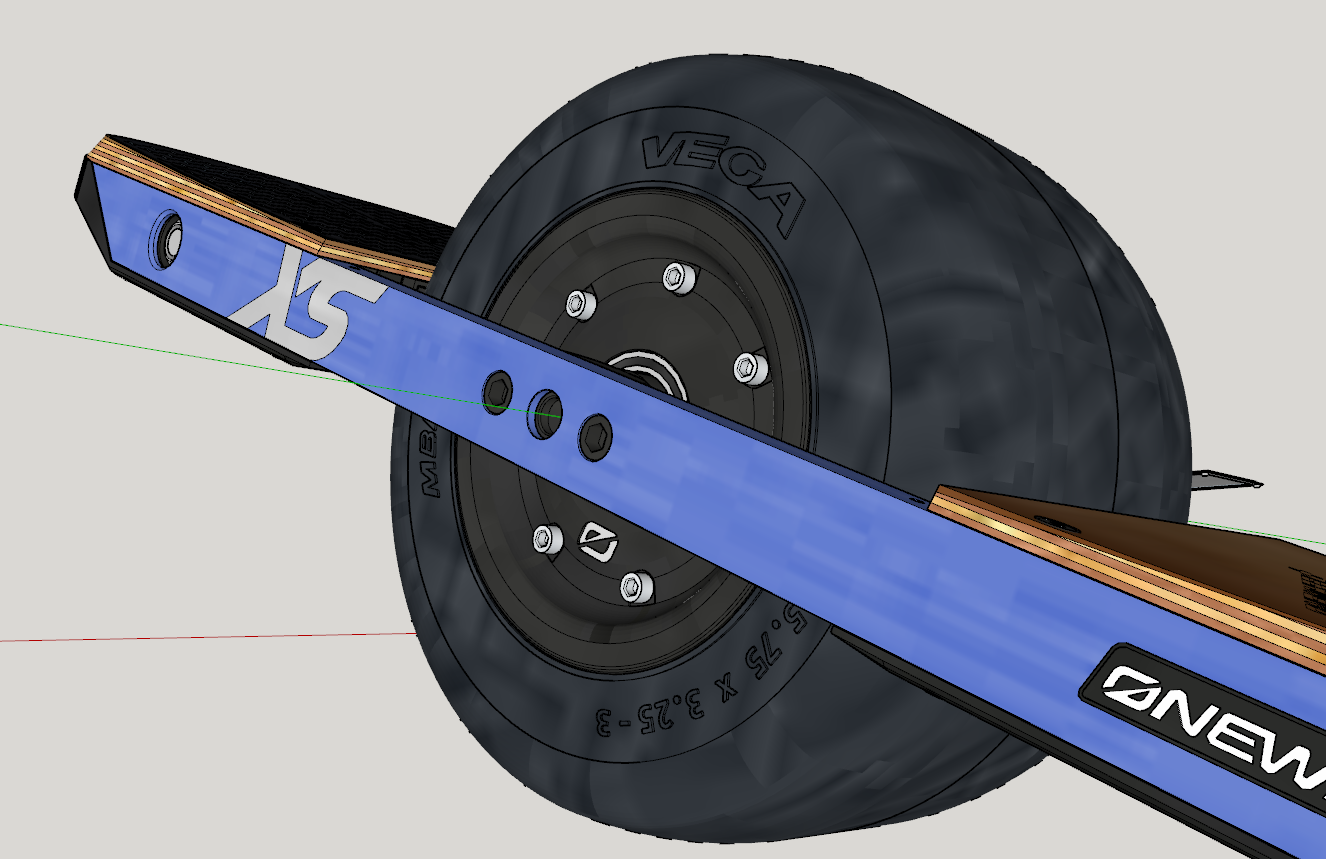

Finally have some more CAD renders :)

-

@lia -- A non-vital shell of a "model skateboard," seven inches long, that looks remarkably like your XS is being marketed by Matthew Shumaker of Tech Rails.

Edit: In the comments on Matthew Shumaker's post on the Tech Rails facebook group, @Lemur (as Fai Leong) posted a photo of a hand-sized XR he built two years ago. @Lemur, please share it here!

-

@s-leon Here's the scale model I built, I thought I posted it on the old site years ago.

I looked at an old picture of this model and the timestamp was July 2019, time goes by fast! First picture was 2019 and second picture is today. I had planned to put led lights in, but I lost interest.

-

@lemur -- Very cute! ...And smaller than I imagined!

-

@lemur I love this, like an XXS. is that actual rubber for the tire?

I vaguely remember seeing this before and could have sworn I managed to archive it.

-

@lemur holy shit! that is tiny!

-

@lemur This is cool! Keep up the good work man!

-

@lia --In the background of the photo of Matthew Shumaker's "toy skateboard" are a surprising dozens of tires to fit it.

https://www.facebook.com/groups/179389331057850/ -

@lia It's a rc car tire that had knobbies on it that I ground off.

-

Don't get your hopes up but... the dust has been cleared off a shelved project once again.

With

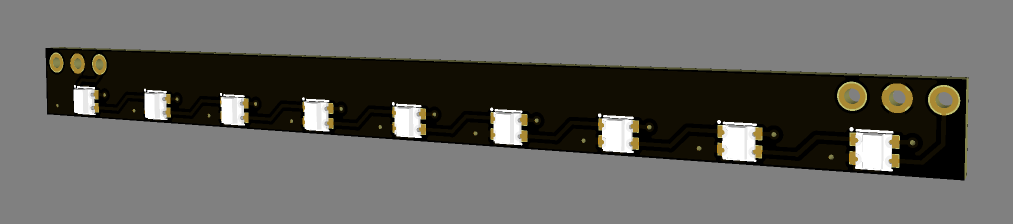

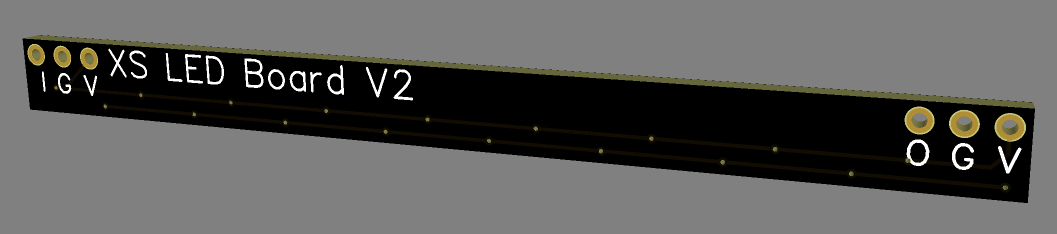

somea lot of encouragement from @cheppy44 I picked this up again and redid some bits I wasn't happy with. Namely the LED driving. I am however waiting for the parts to come since the LEDs and PCB are being shipped from China.Nick pointed out I could just use addressable LEDs which I'd formerly written off since I wanted to keep the style the same. Being the idiot I am I forgot I can just... program them to be identical to stock anyway. Duh >.>

This removes the need for my abomination of an LED driver board and I've been made aware if the Seeeduino which I'll use in place of the Arduino Pro Mini that's taking up more space than needed.

With the LED's being 5v and data driven I can run a single 5v line off the FSESC then use just a data pin to string the LEDs together. Big brain. I'll butcher the power button and put one of the addressable LEDs in it too to get the flashy blue light we all love once again since... I... er... kinda melted the first one >.>

In using smaller LEDs I'm also able to fit the full 5w 4r rather than just 4w 3r like before. Further keeping in theme of being an accurate as a working scale model as I can get.

I'll redo the CAD once the parts turn up. Wish me luck. I want the following done before summer.

- LEDs fully functioning (again) and responding to motor direction.

- Functioning power button.

- As close to colour accurate rails as I can get.

- Custom made rubber tire.

- Accurately etched/painted decals and griptape design.

- Resin printed bumpers and hub casing.

- A cute letter from Kyle asking for one (totes not happening but I can dream lol).

-

@lia I AWAIT FOR THE NEXT UPDATE

I now have something to look forward to, thank you

-

While waiting for the new components for the headlights and power button LED I've started work making a master tire to create a mould and later rubber cast a solid tire replica.

First up was redoing the tire model to be rounder and reprint. The entire thing was over 24 hours of printing because I was doing it at a 0.12mm layer height. Then I added some wood filler to fill the seam in the middle. Lots of sanding later I got a smooth enough surface.

HOWEVER... that's not enough so out came the filler primer and I managed to completely smooth it out. The ics don't do it justice how smooth and nice this is to hold.

Trouble is I haven't cast anything ever and trying to figure out the best the best method while also not over-complicating a mould. Then I also need to decide on the best materials to use for both the mould and actual tire.

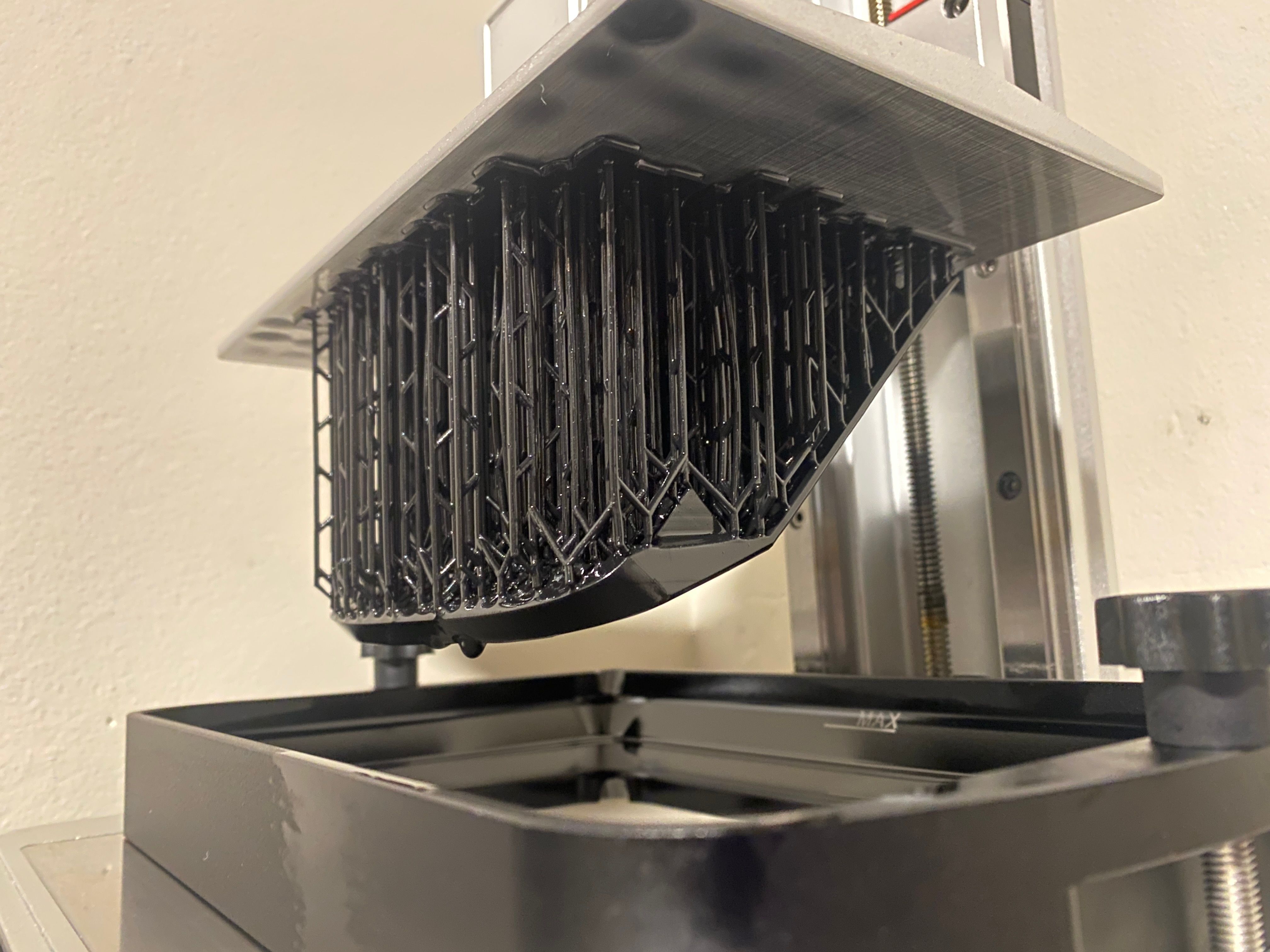

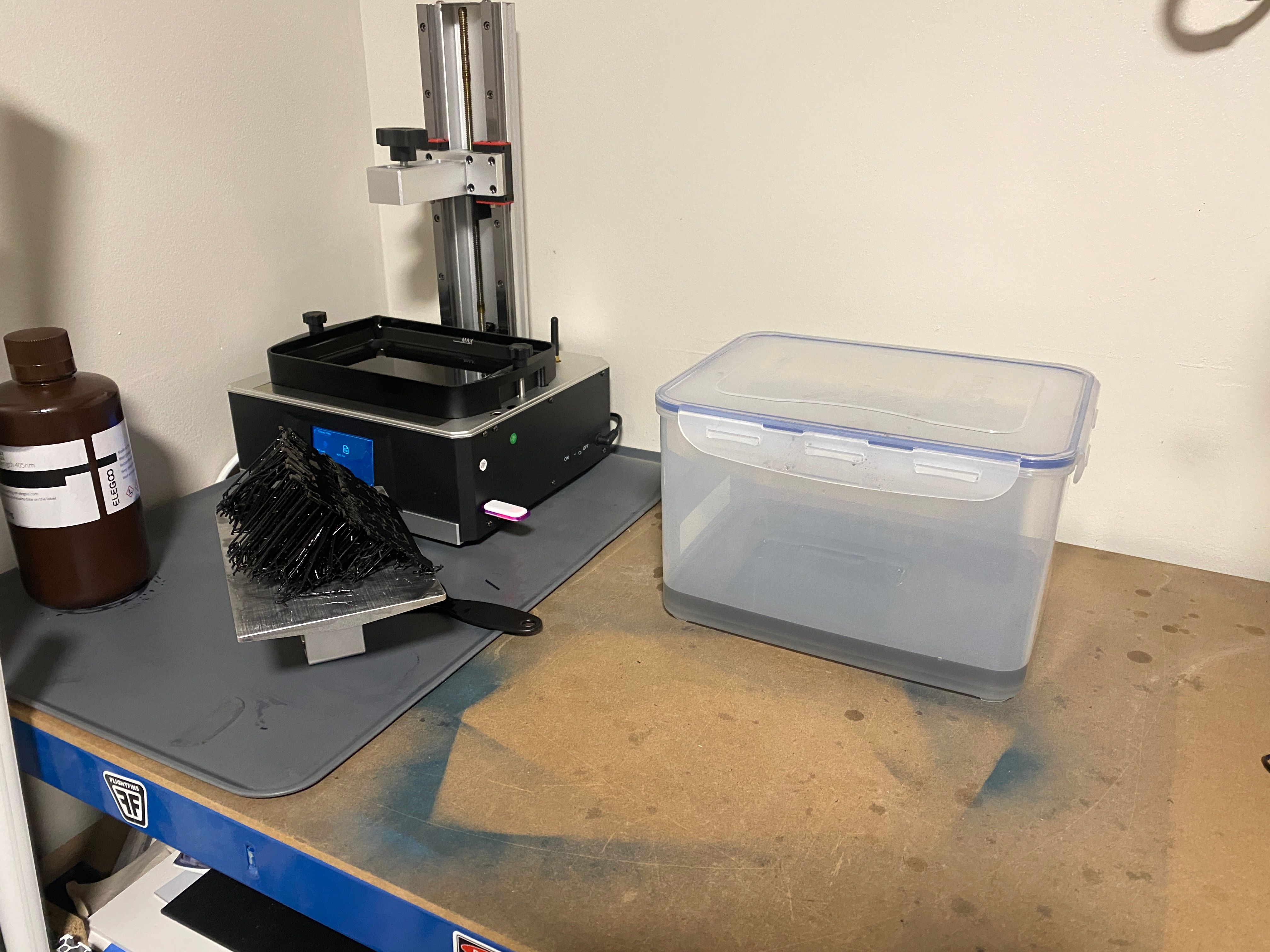

So while I figure that out @cheppy44 convinced me to give the resin printer a try. I've been holding off using it because the idea of getting in over my head on yet another CNC based workflow is daunting. However... I at least managed a successful print.

Woke up to find it finished waiting to be removed from the bed, supports removed, washed and finally cured.

It looks good, other than some artifacting that I'll need to figure out.

Tore off the supports which went smooth and was oddly satisfying sliding your fingers through the supports to pull them off.

At this point I had noticed some odd white smears which I think was me not letting the iso-alcohol to dry before curing in my DIY cure station.

Wasn't prepared to pay like £200 on a wash/cure station that fits the models I make so £20 in some specific bits was fine for me.

You can see the difference, if not for the white smears this would be night and day in an improvement.

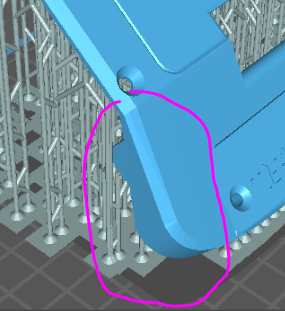

Sadly it looks like the print wasn't perfect. The very front appears to be warped and doesn't actually line up as per the CAD as shown with the wildly out of tolerance bits below.

For a first print though I'd say this is pretty good. I think the issue was the parts that warped don't appear to have any support.

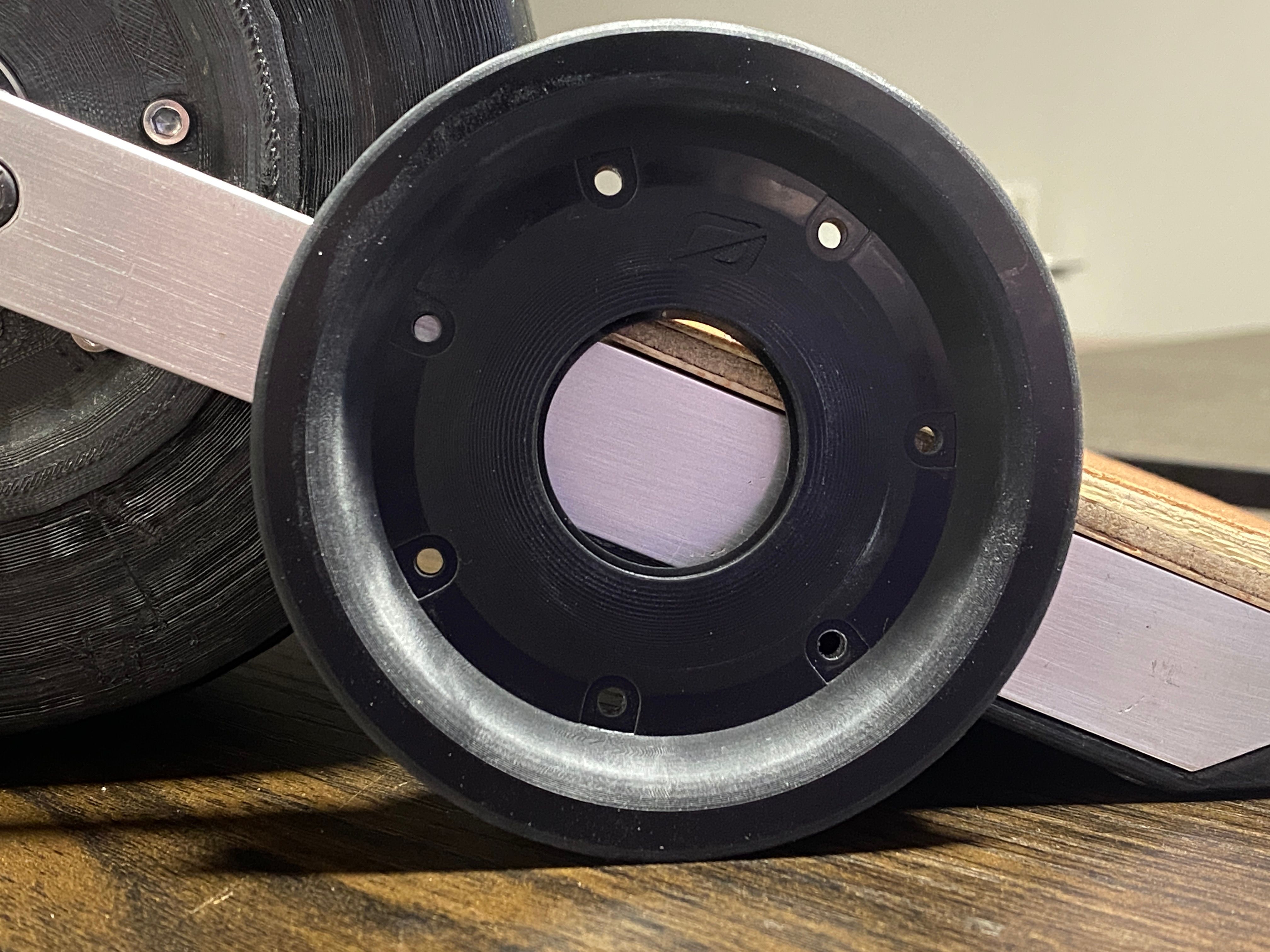

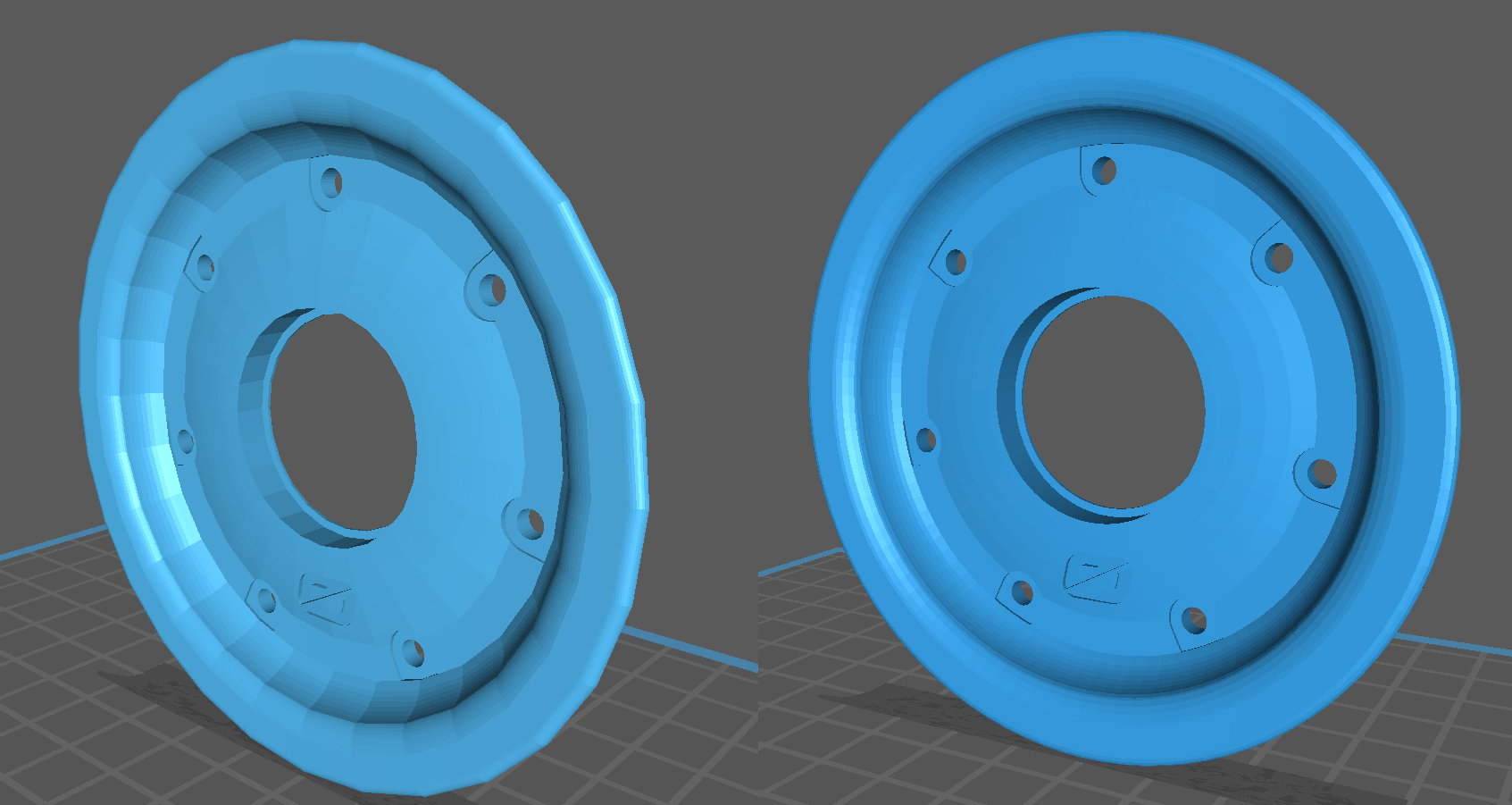

I'll try that again but since that took 9 hours to print I've opted to do one of the hub face plates which is only 2 hours. It did mean I needed to remodel it. See before/after (don't worry I wasn't printing in this orientation).

Edit: Left hub cover finished, impressed with how good the parts look!

Next to the old one that's still on the XS. Waiting to get the other side done before taking the hub apart to add it.