Followup to the Onewheel XS

-

@maciak So happy to hear that <3

It is tempting, make a few commissioned ones for some riders. If I do have a change of heart and consider it I'll let you know ;)

-

Everything is on a "go-slow" especially with work driving me insane. Feel like there's been enough progress for an update though :)

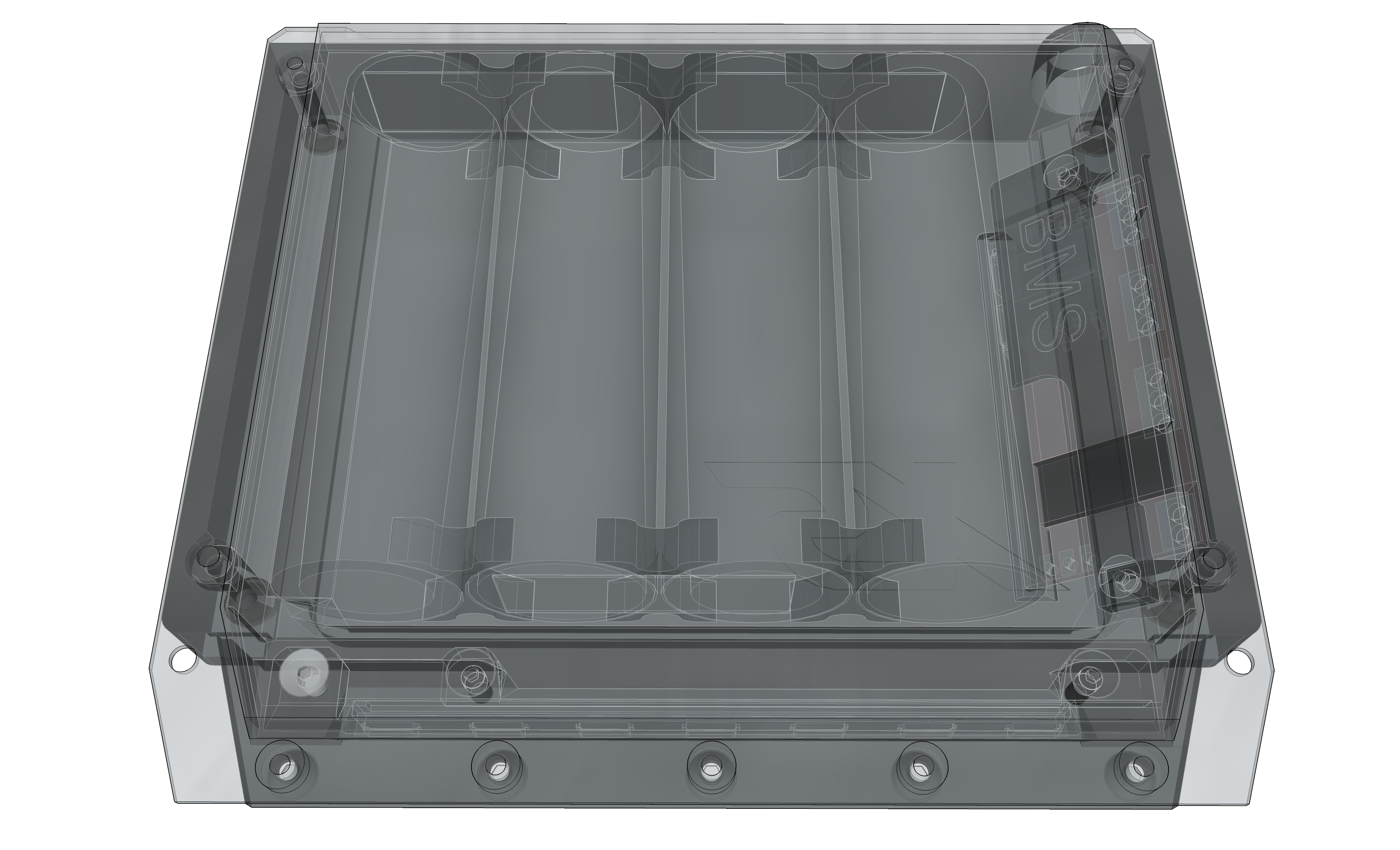

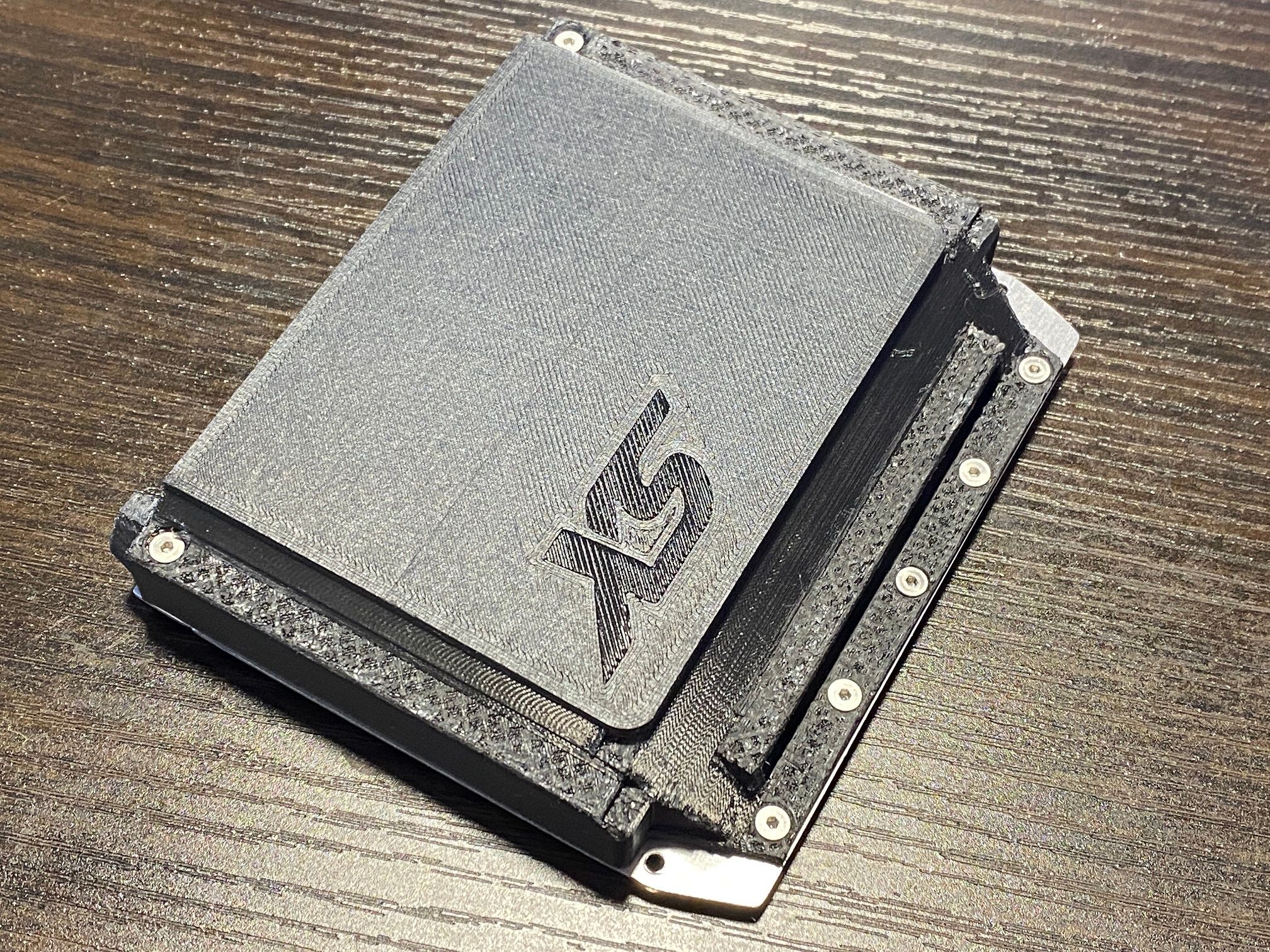

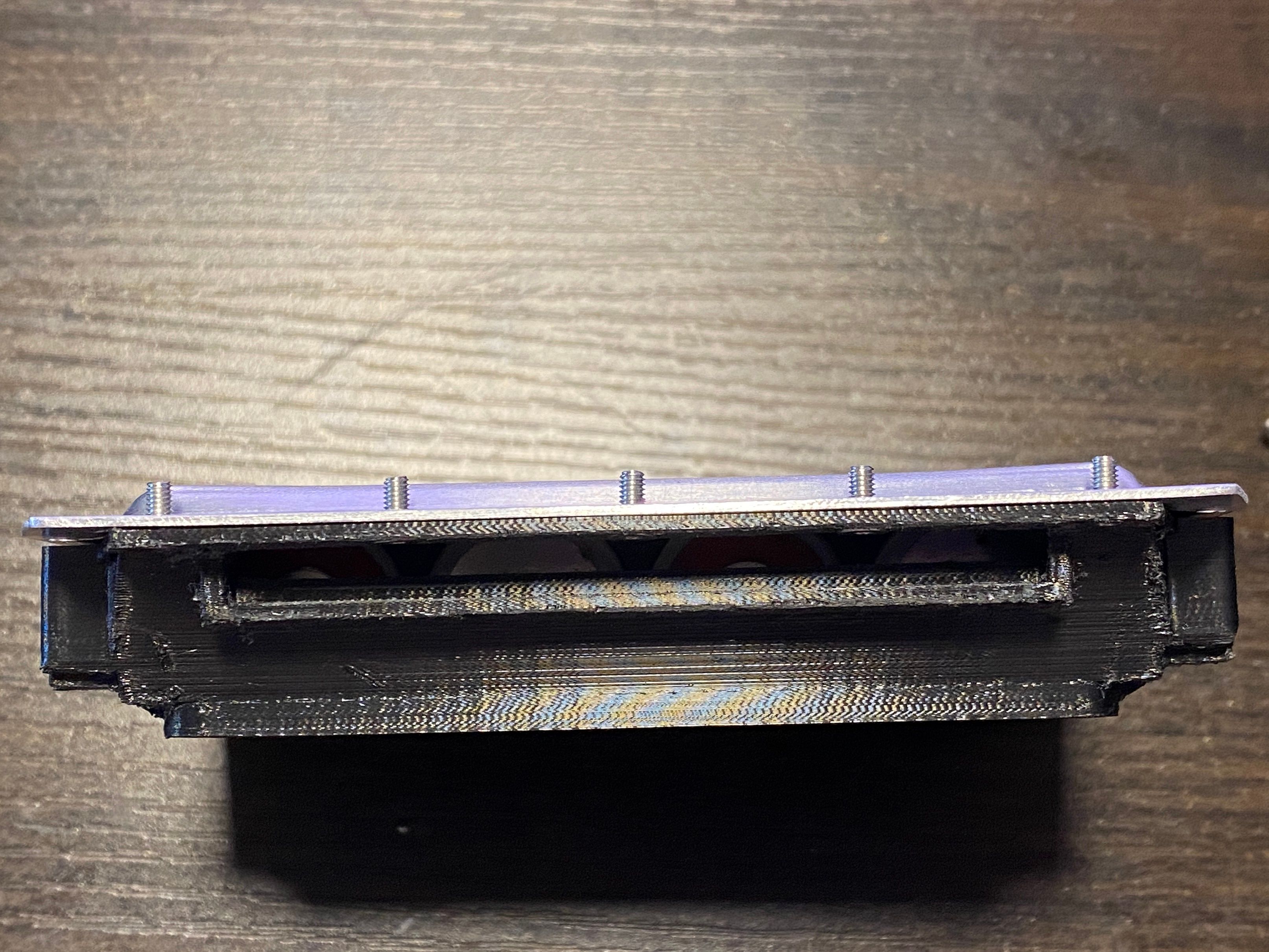

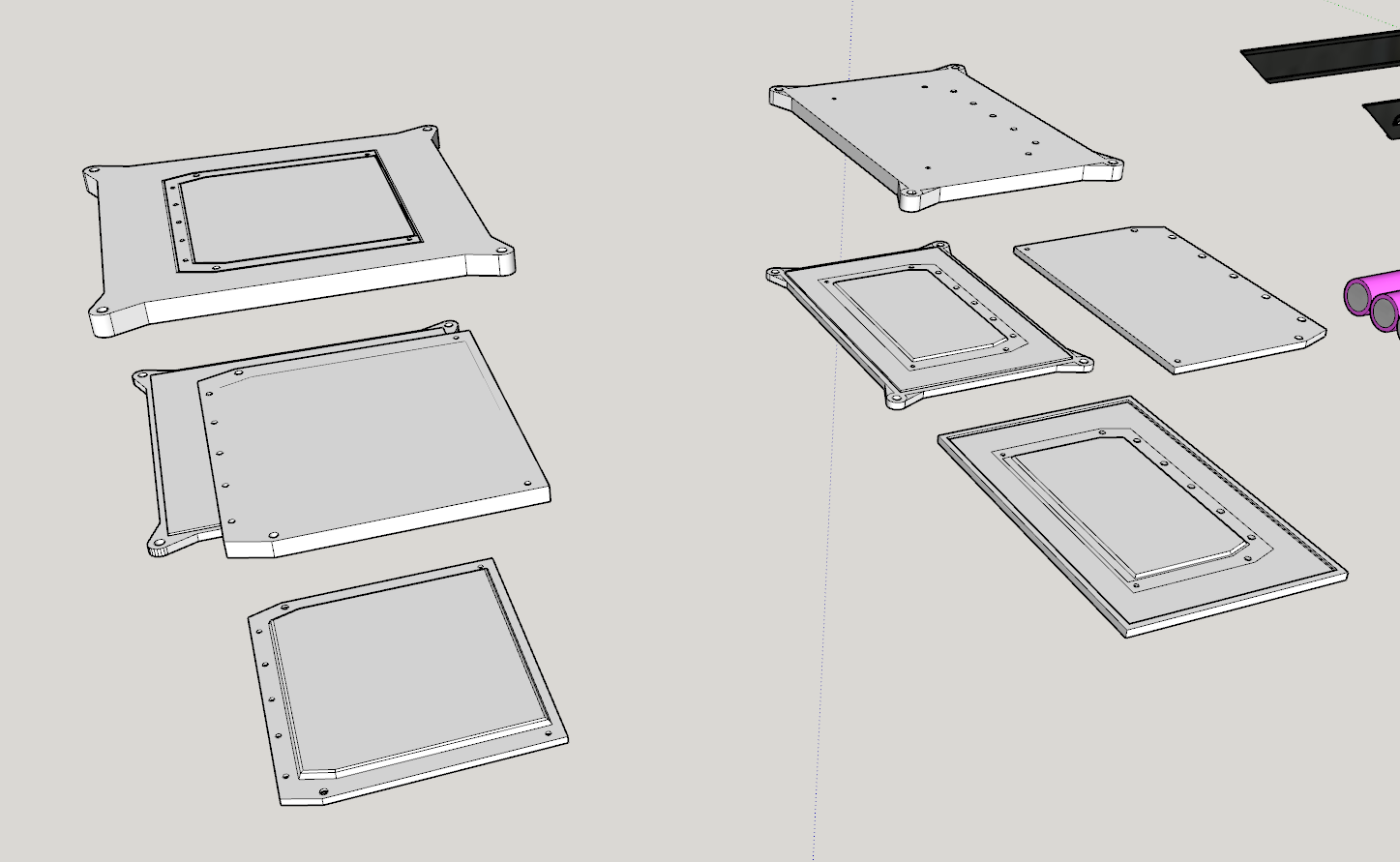

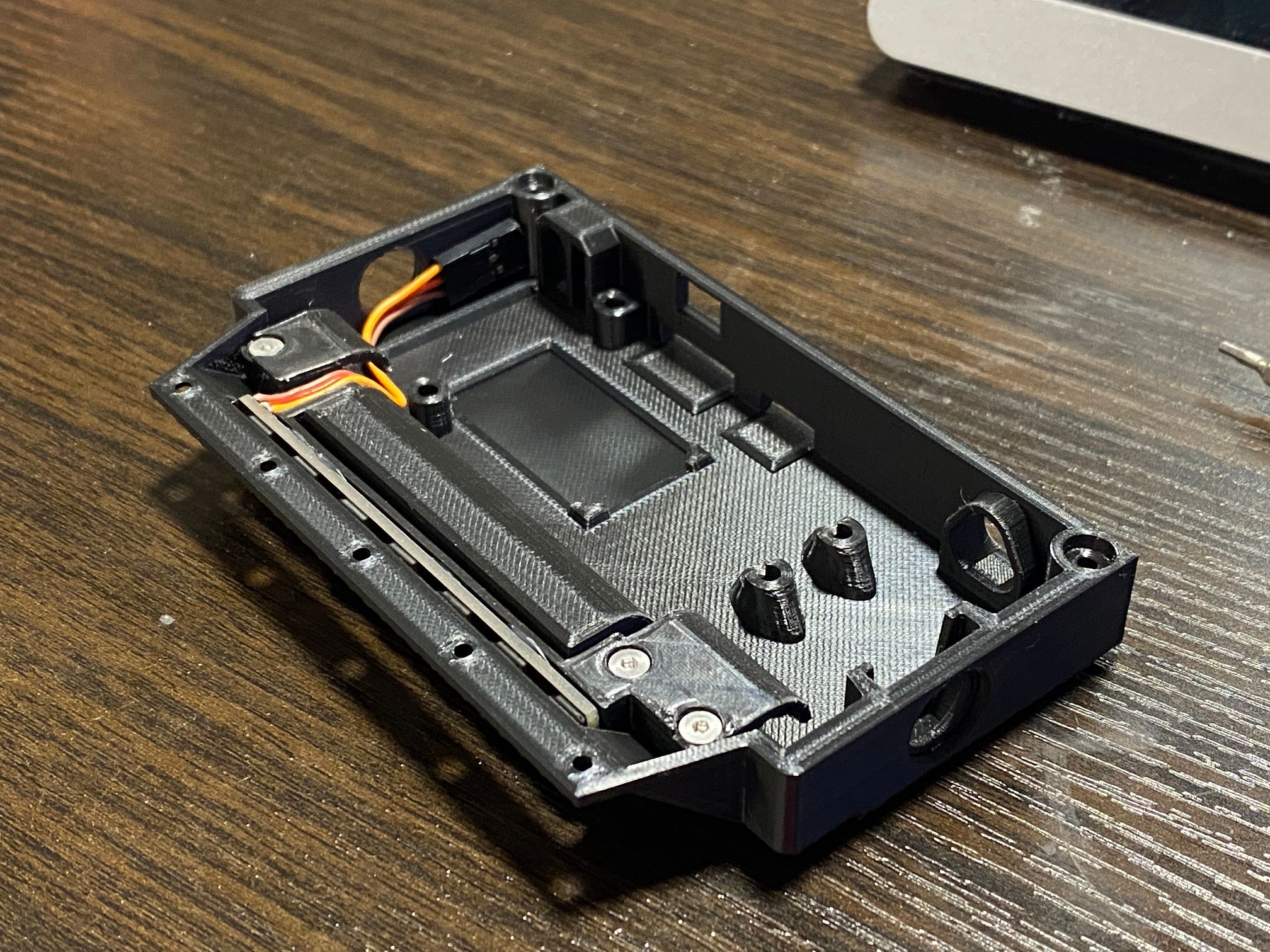

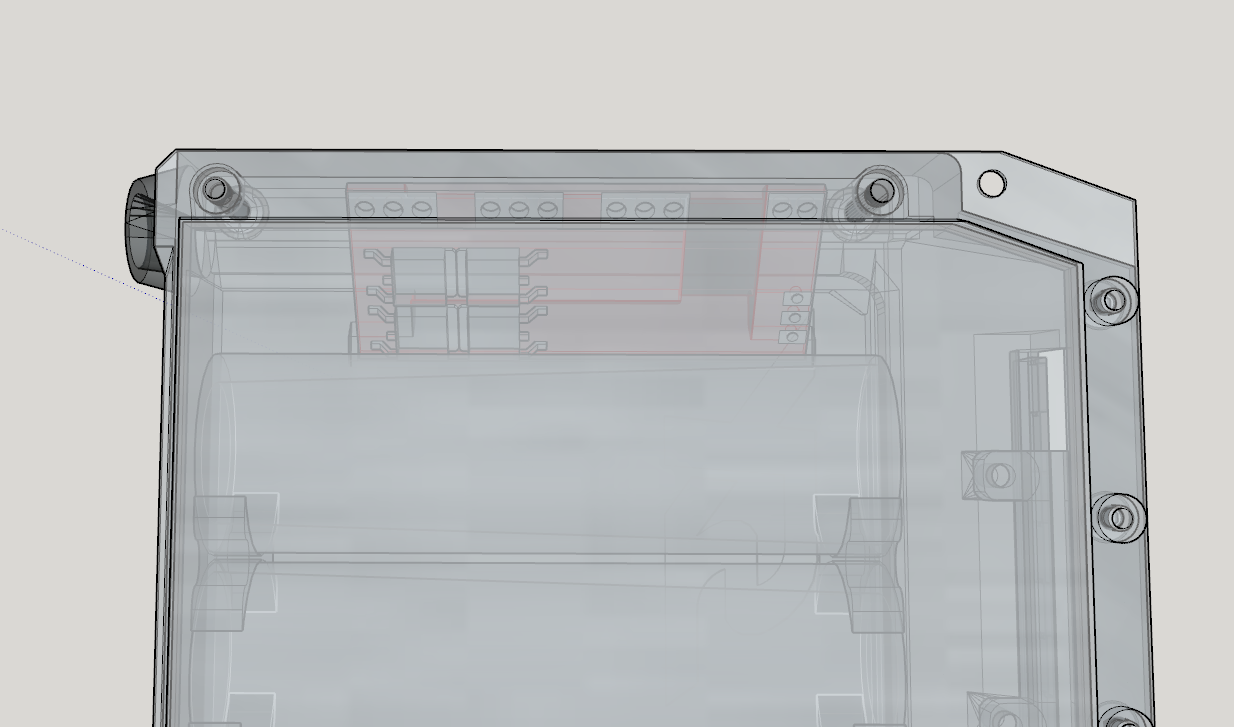

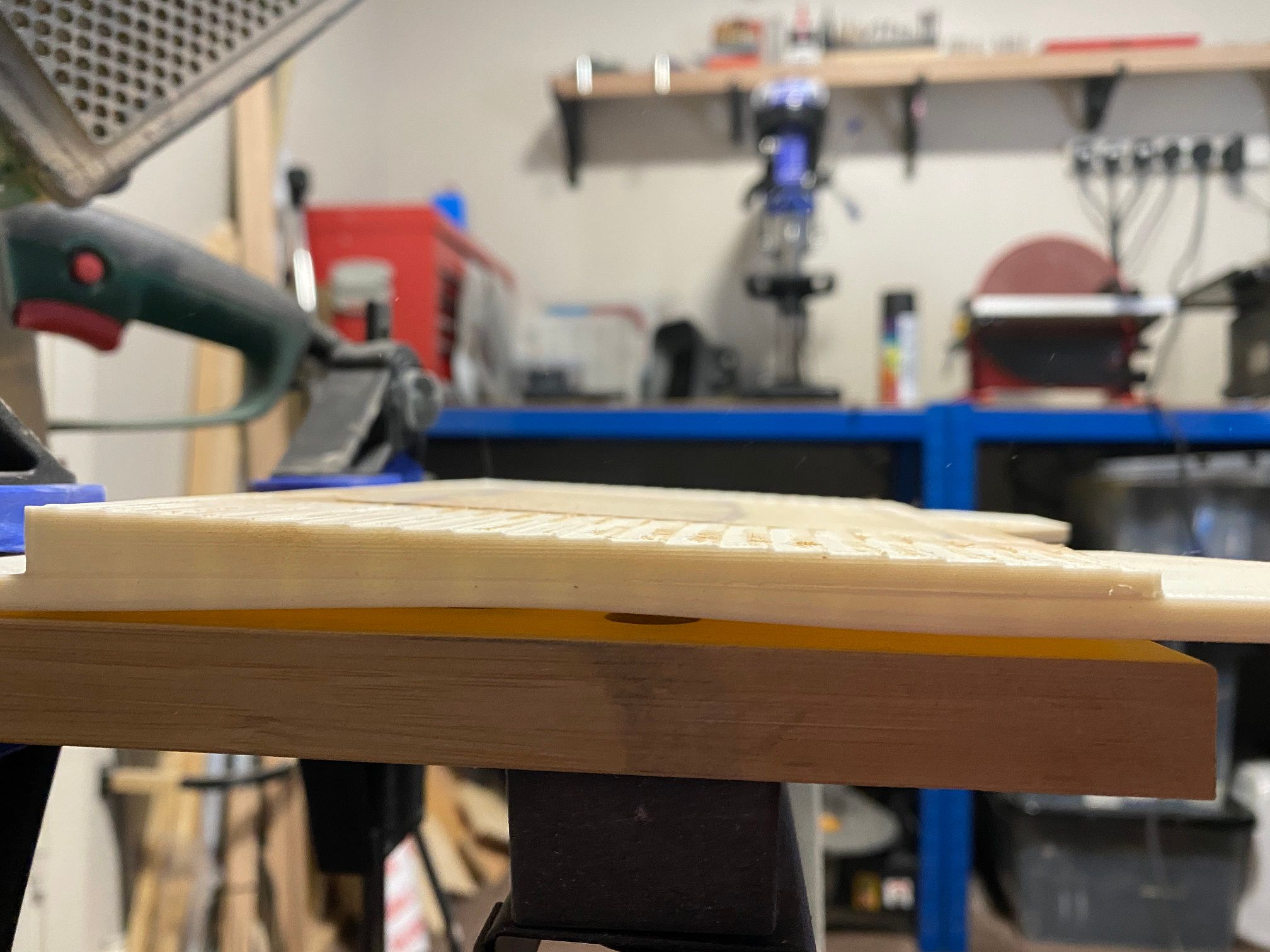

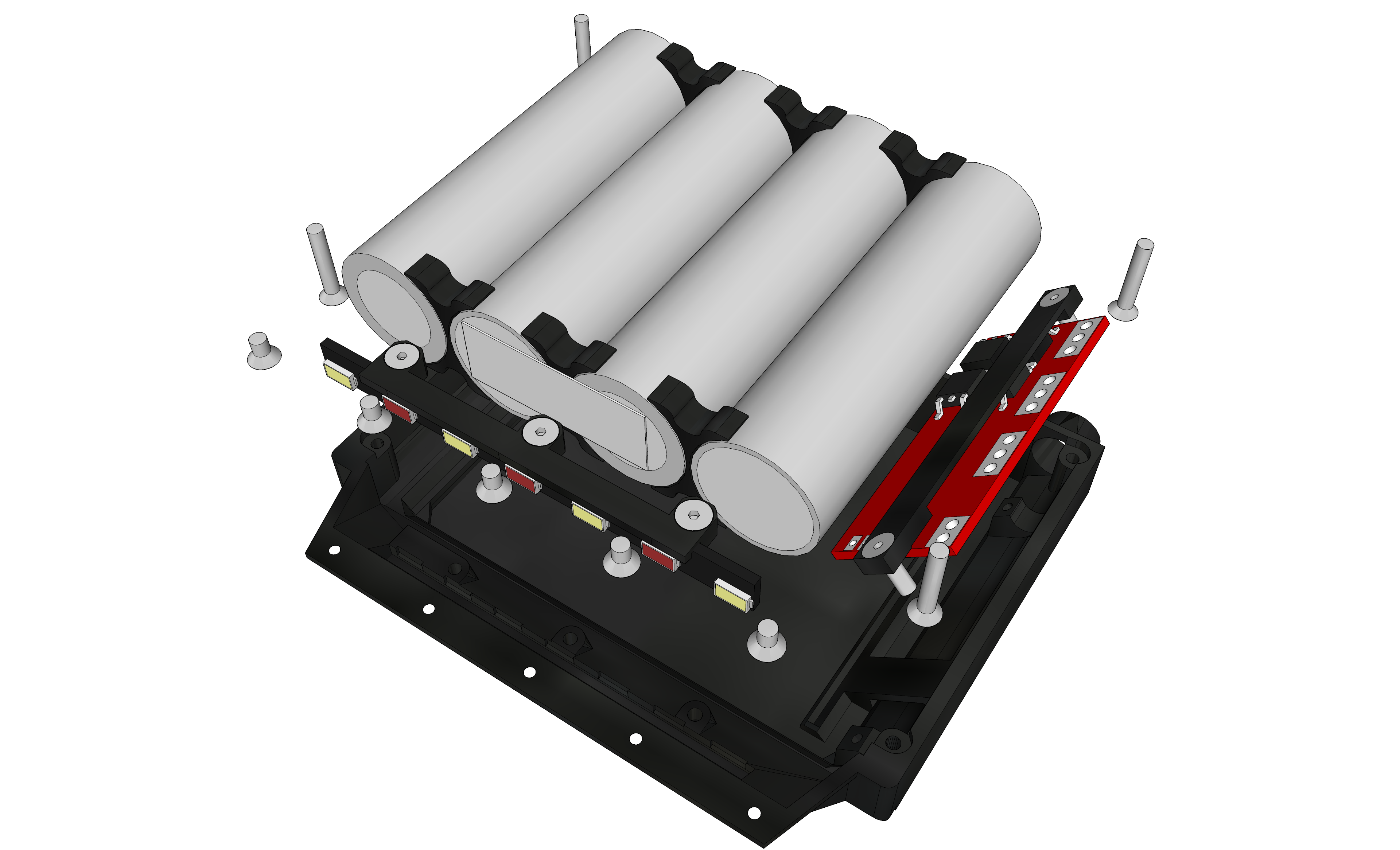

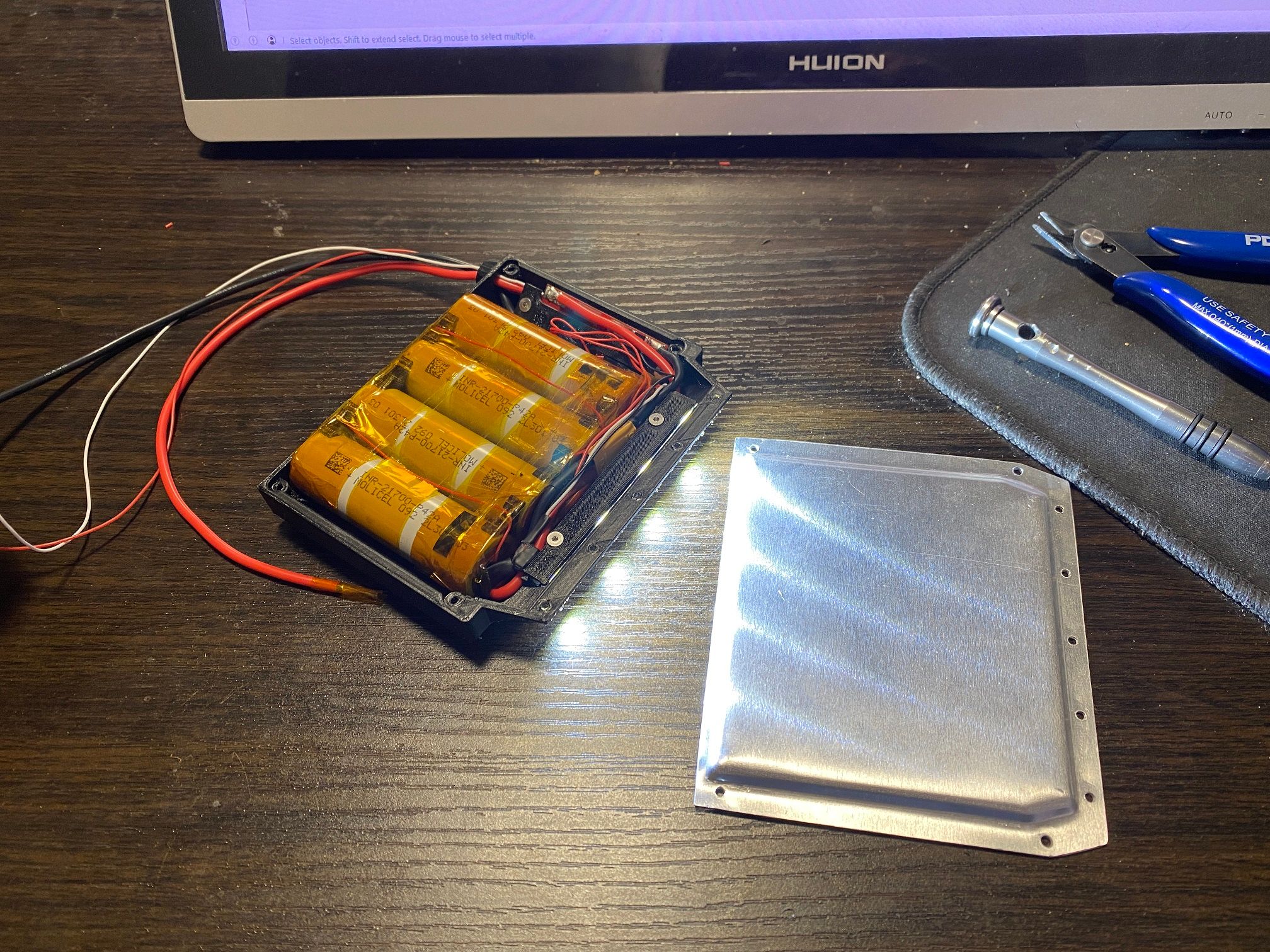

Battery housing lid before being trimmed to size.

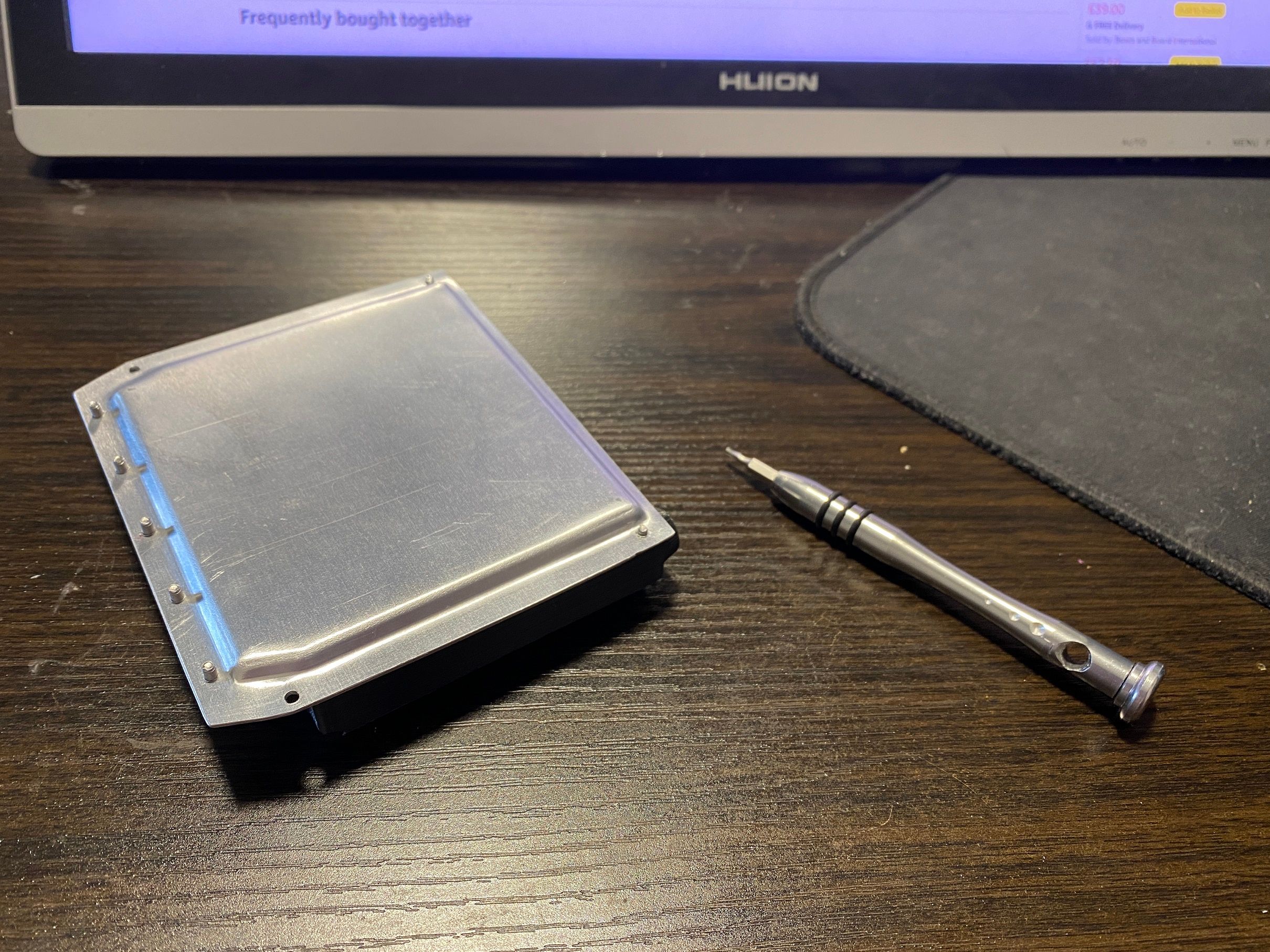

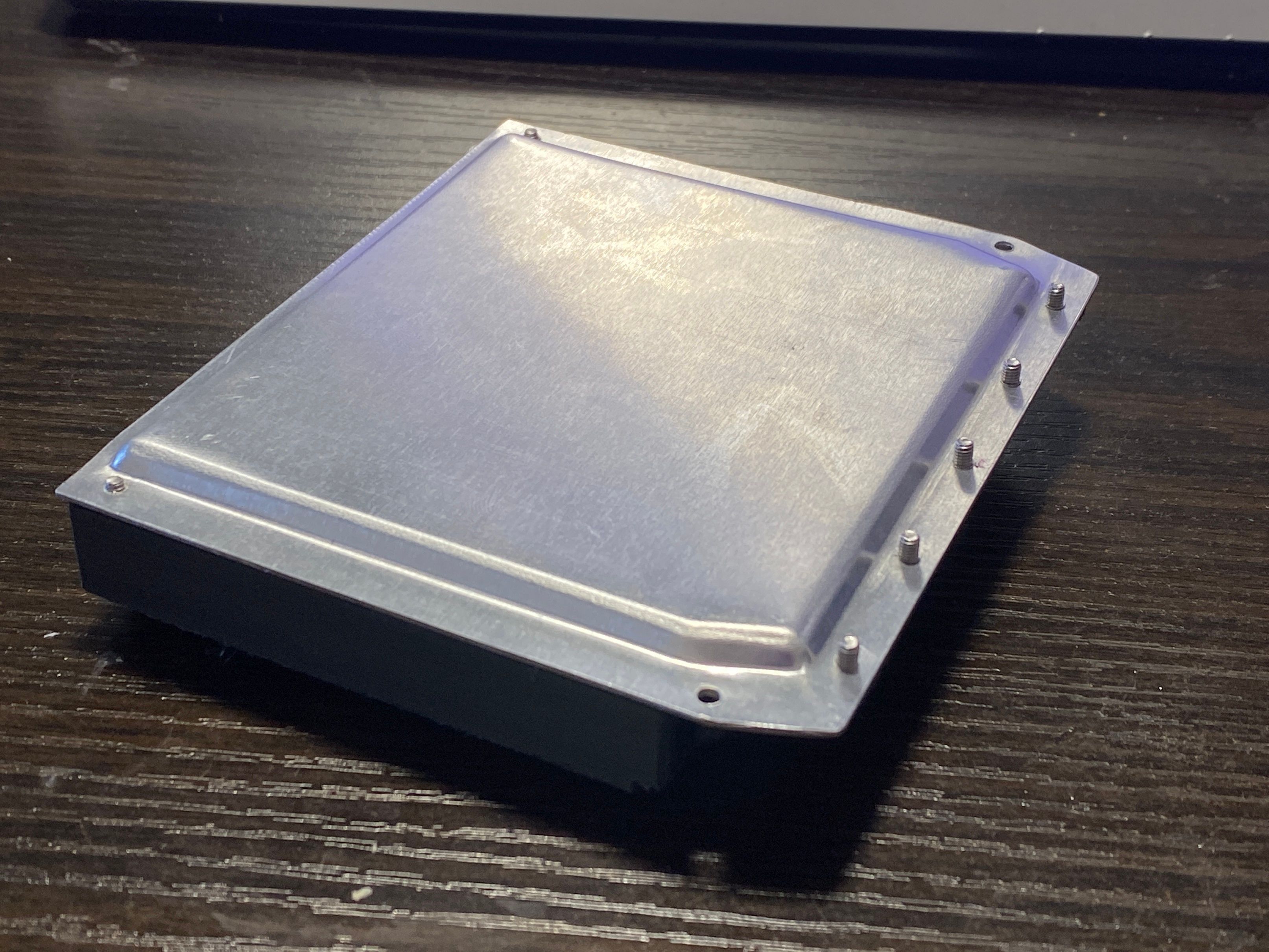

Cut the lid to size, still need to add the extended threaded sections since the 1mm plate is not going to last.

Cells fit, need to push up the middle of the lid as it's deformed in a tiny bit but other than that it all fits :)

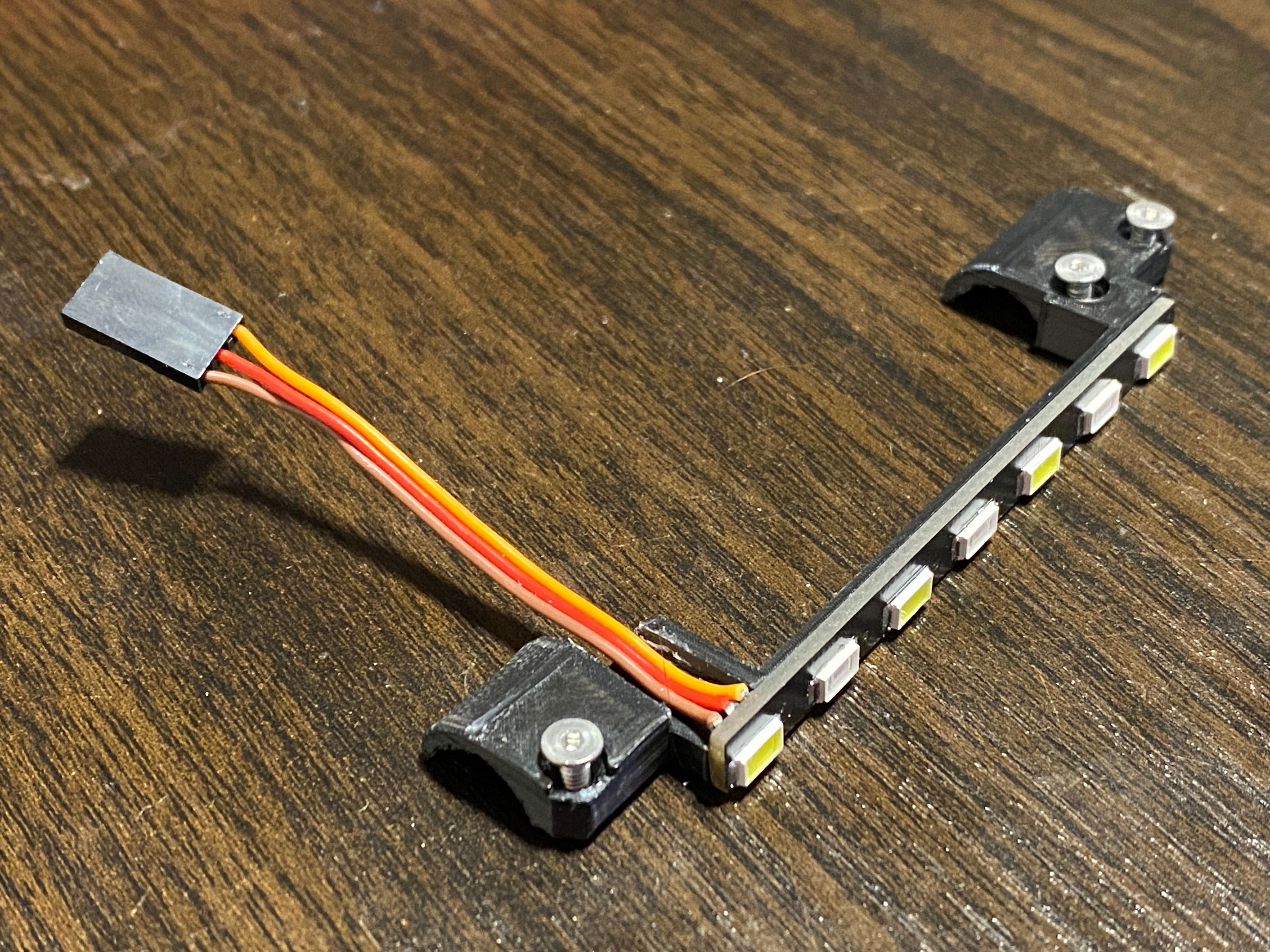

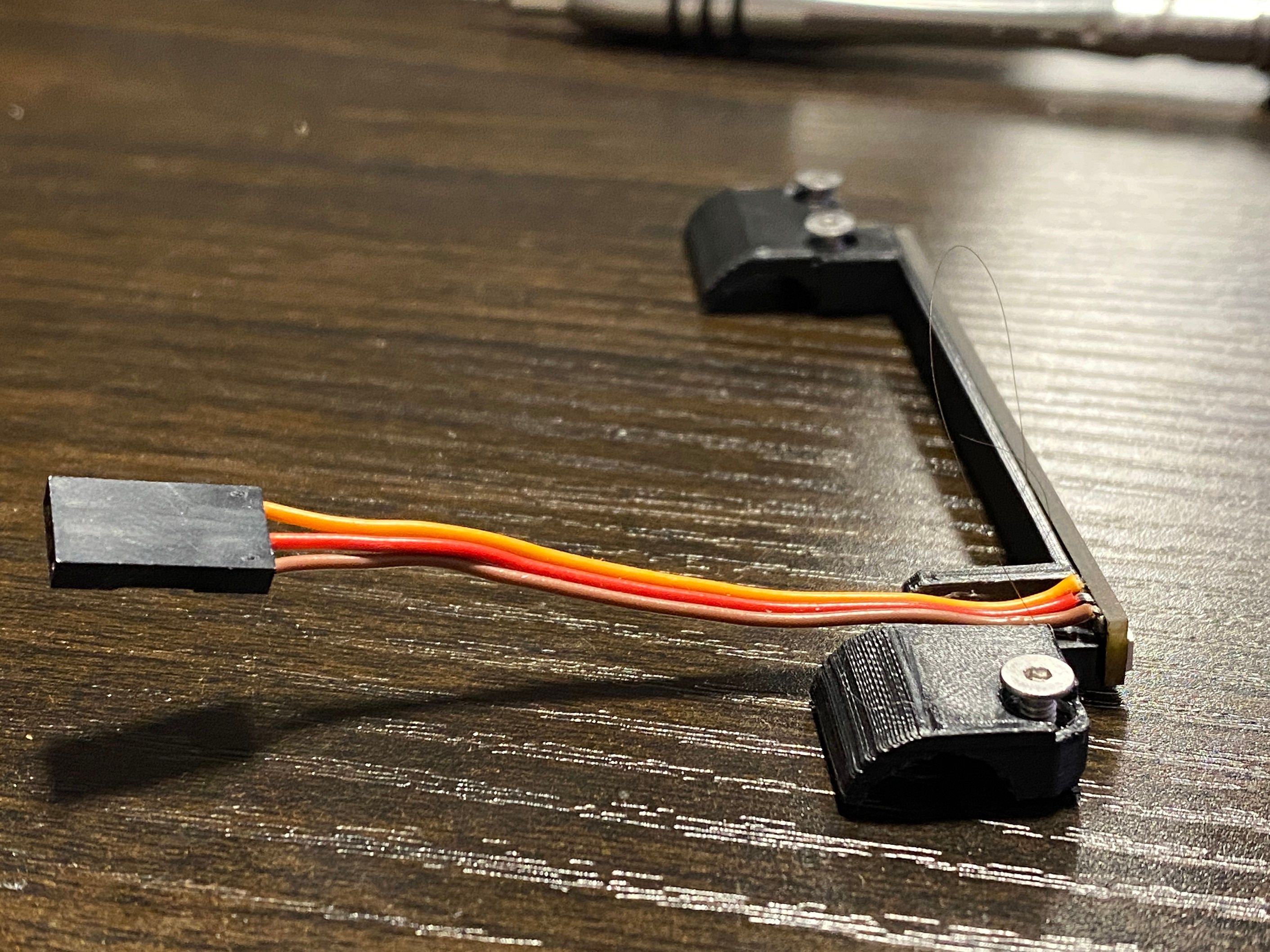

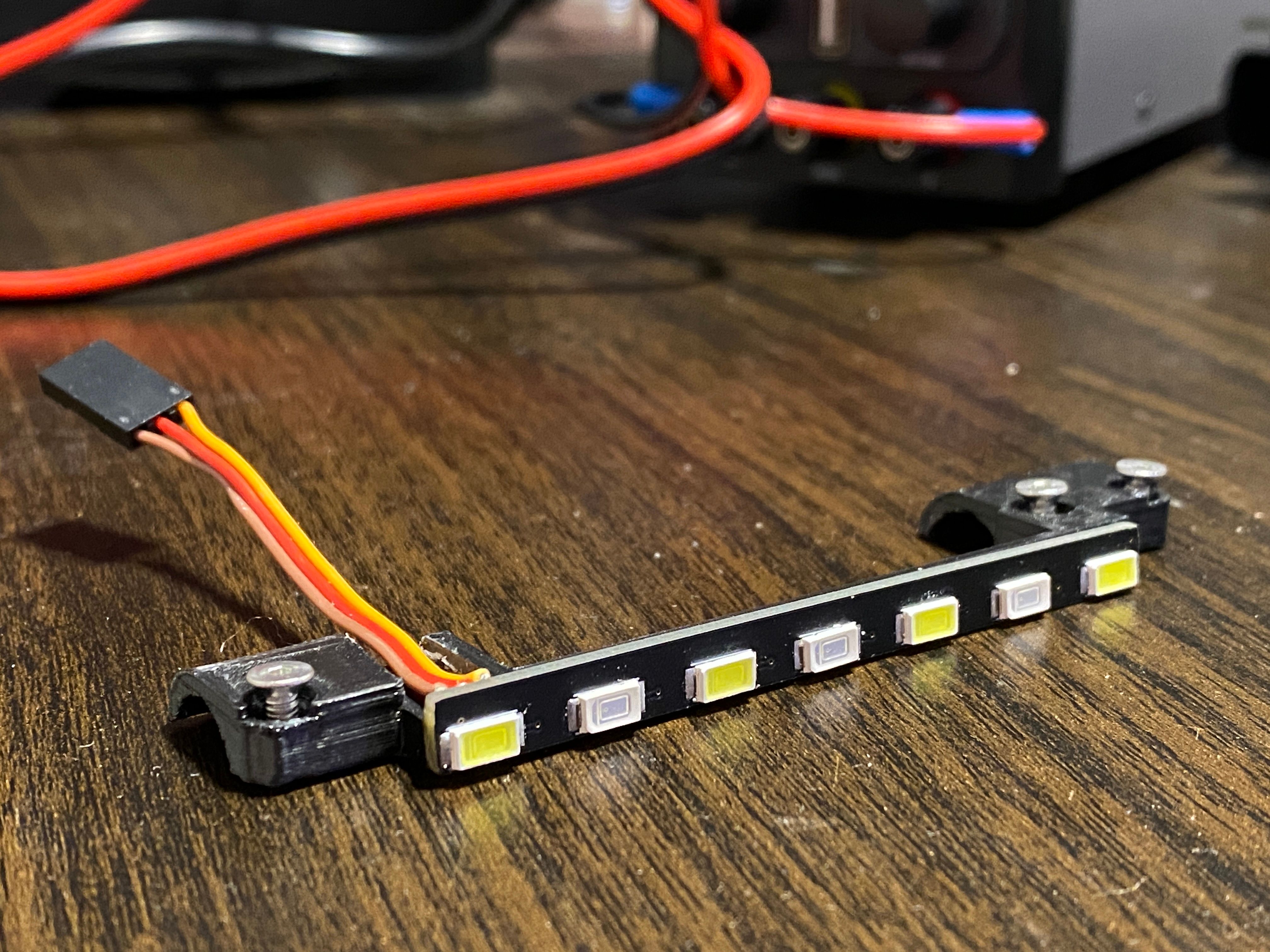

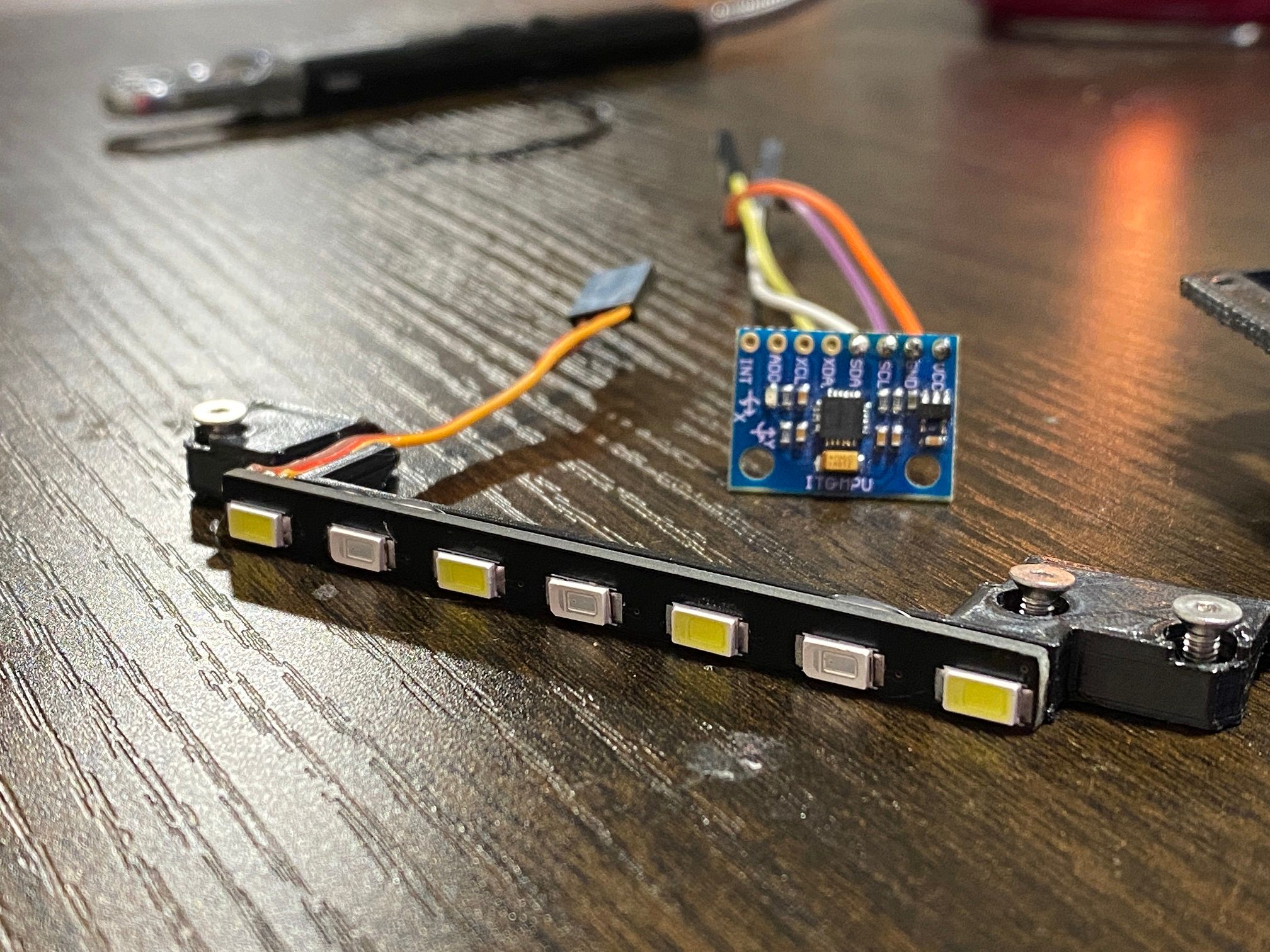

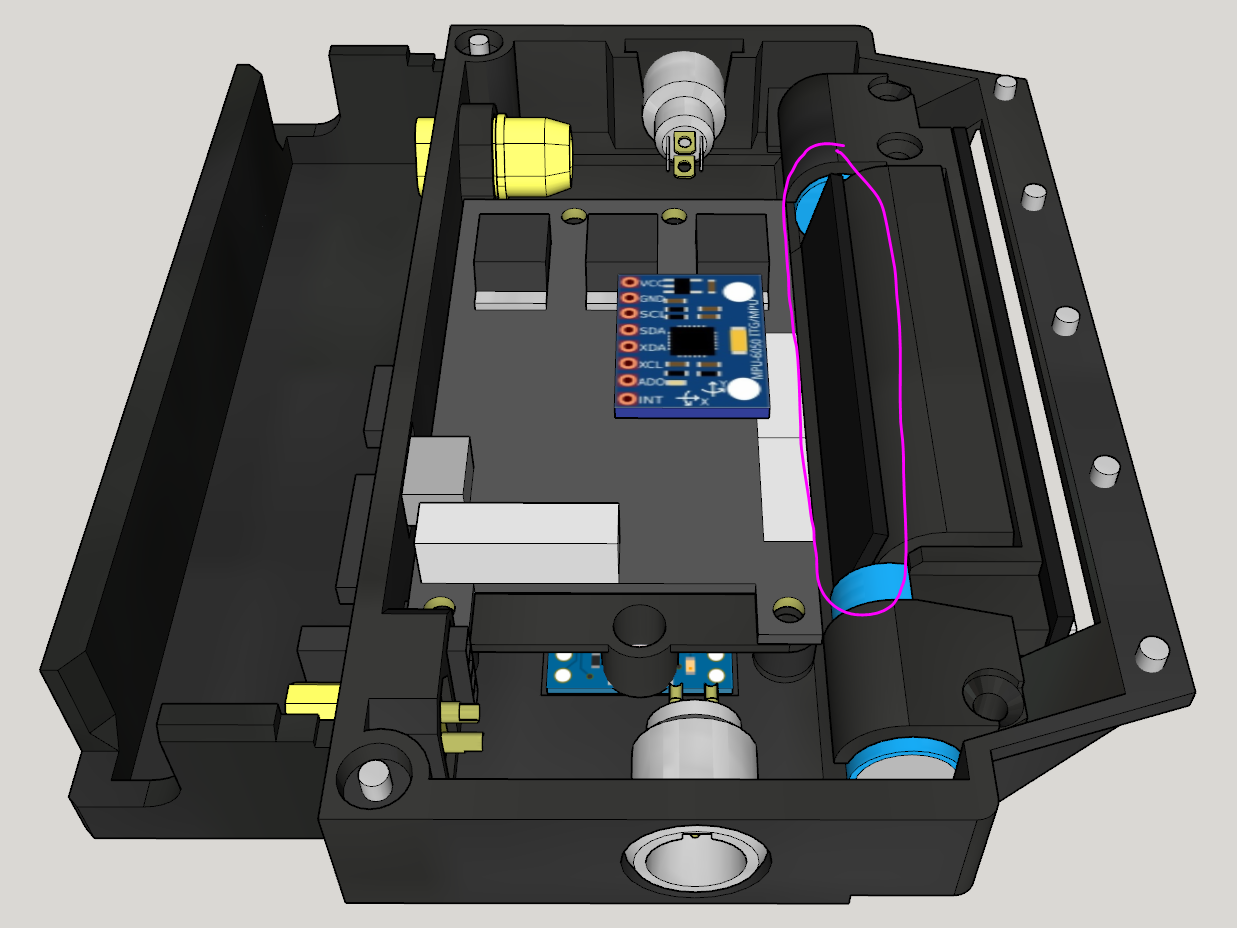

Made a new bracket for the capacitors that also will hold the front light bar. Got iPhone vibes from this part. Anyone that's taken apart an older iPhone and seen how things like the speaker look with the long tiny plastic brackets will know what I mean.

Unfortunately there is a 0.5mm clearance issue with the LEDs so it's hard to remove for now so I'll redo the lower controller housing to accommodate this.

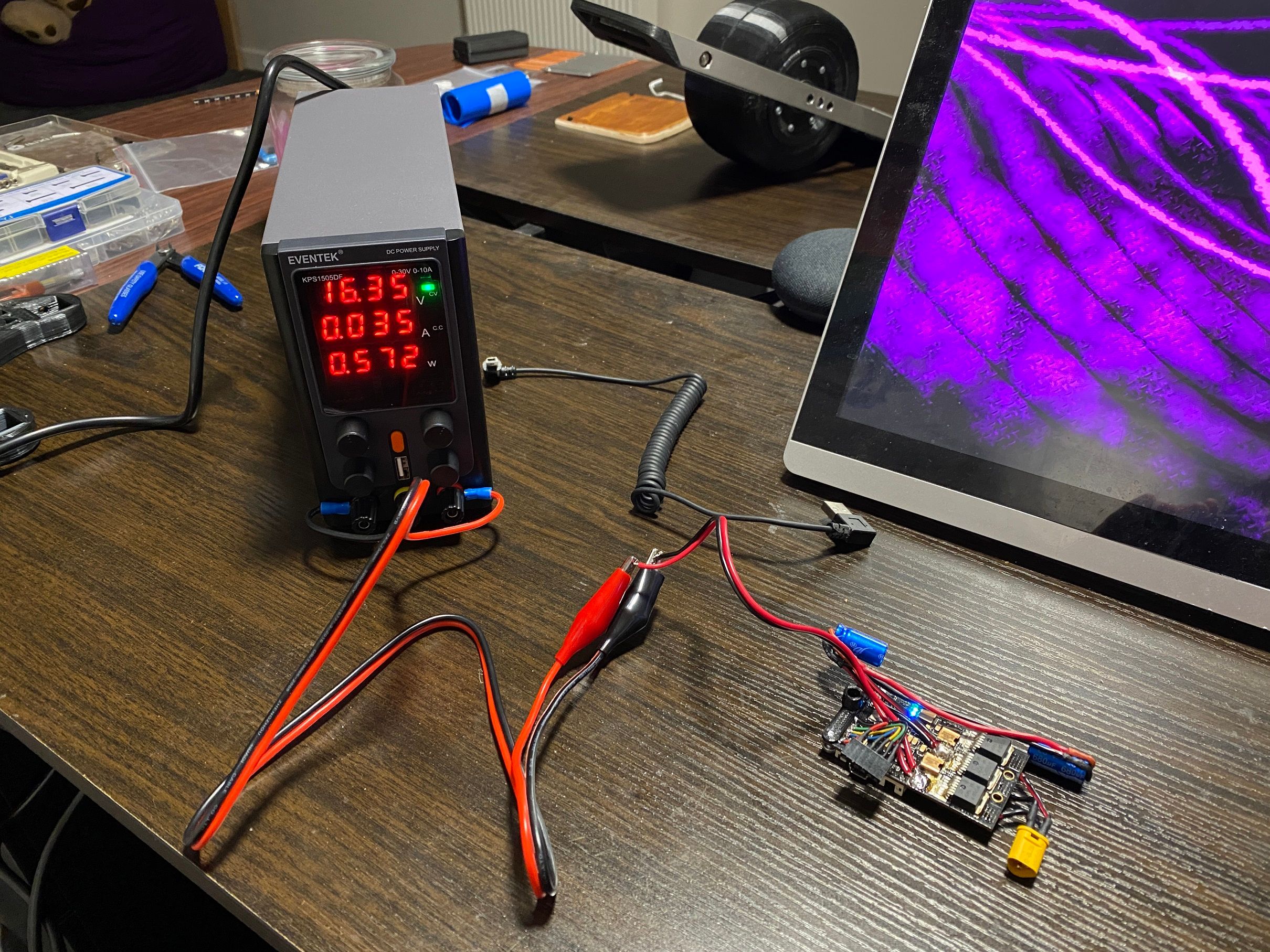

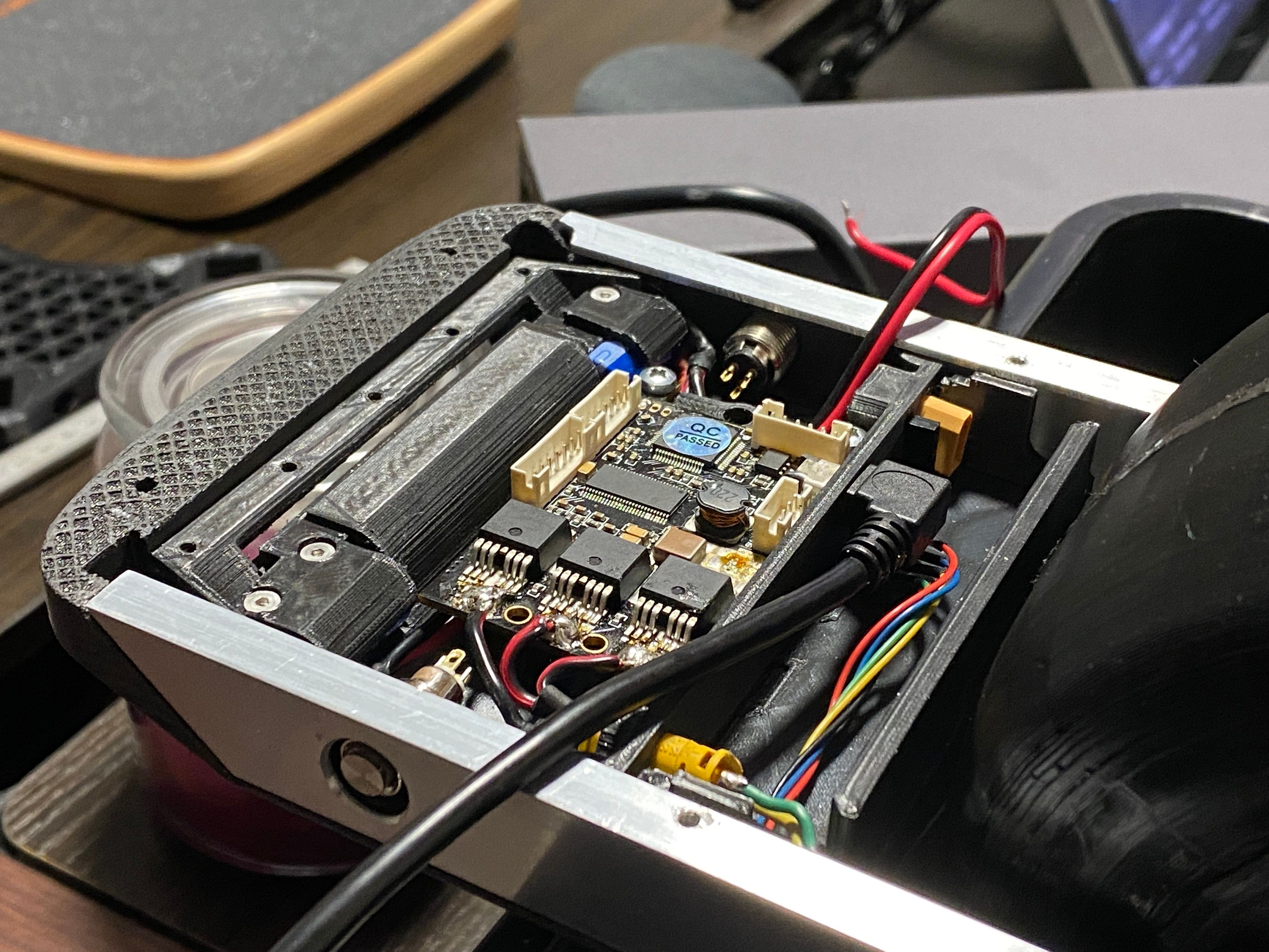

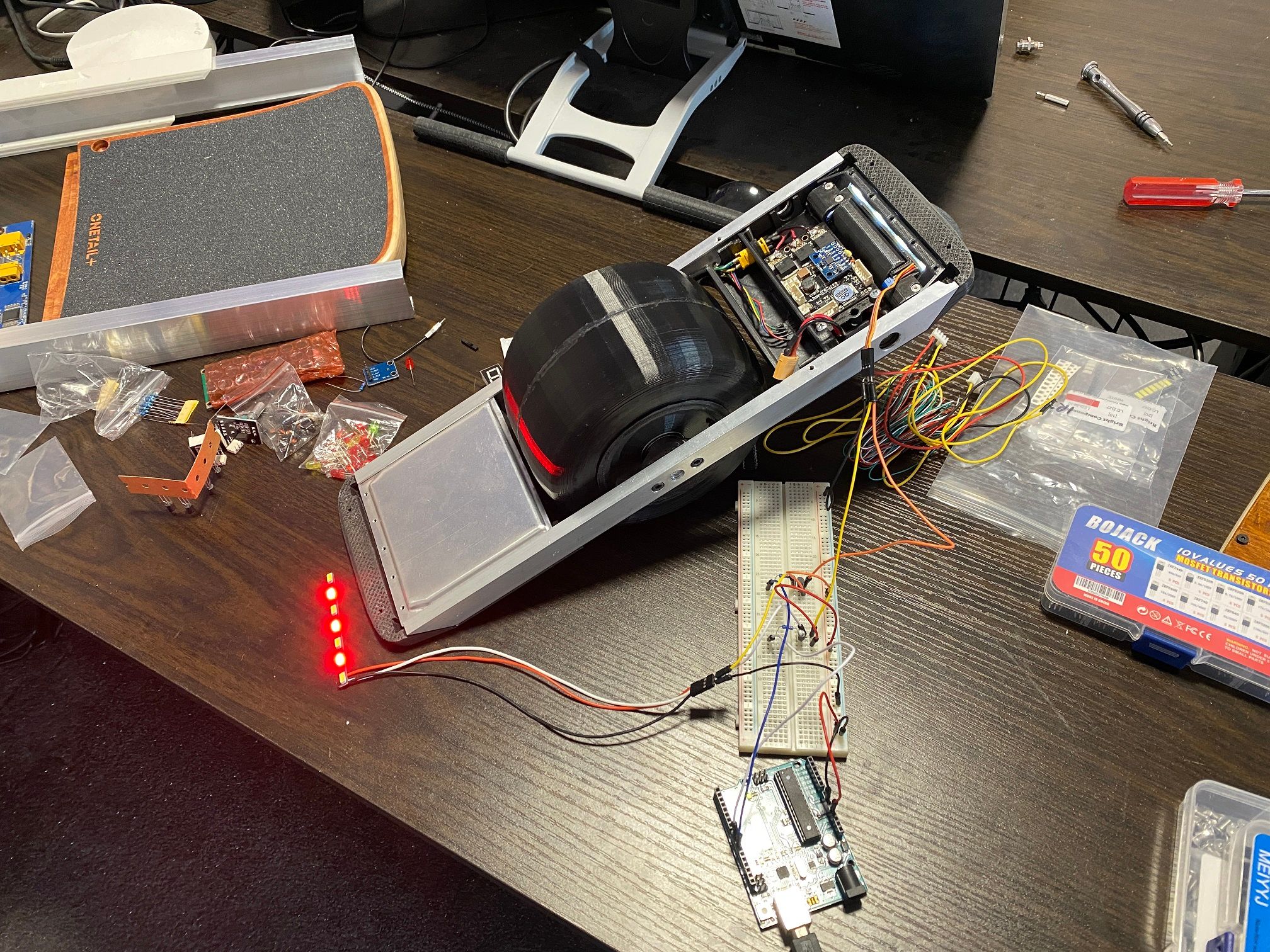

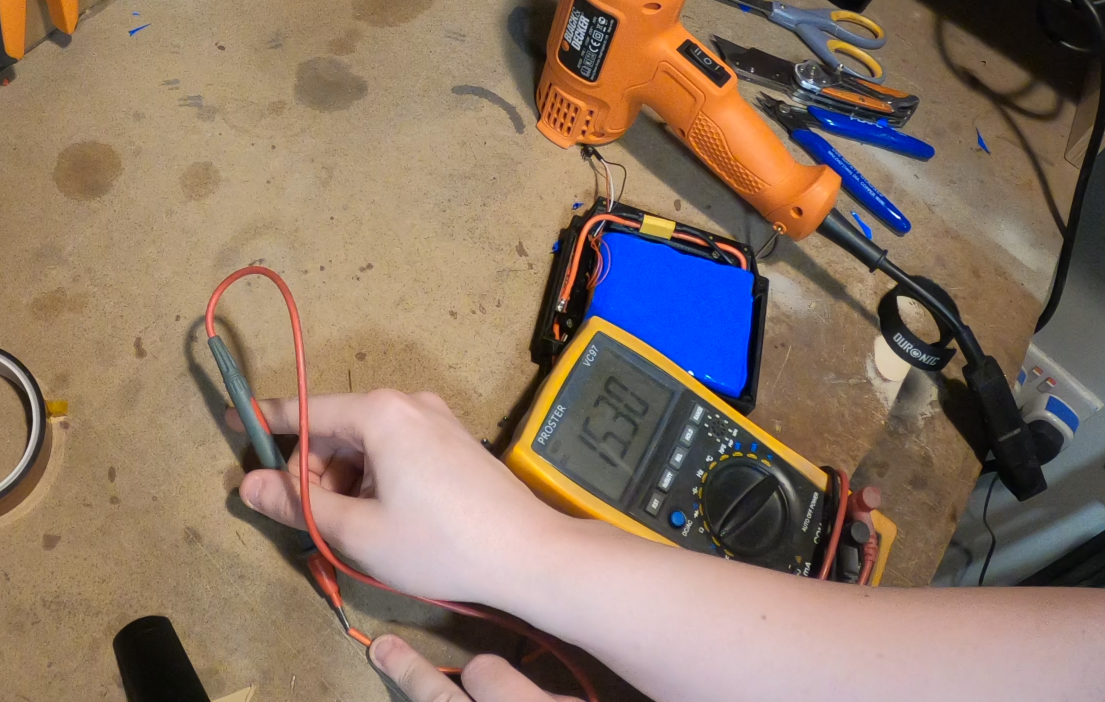

Finally it's come time to test the electronics... D:

So far so good, no fire. Set the PSU to around 16v (4s) and only a max of 5amp rather than the full 10amp this can do. Time to mount it back in the XS and test the motor.

Time test see if it spins (sorry for the crap footage, the lighting mixed with a smudge on the lens makes it look hazy AF >.>)

It works~ :D

Rattly but works. Need to braze the axle bracket and rail together which will stop that since those are loose and definitely the cause of it. To be fair it only does it when spun up max speed (under current settings) so I'm happy with how it is so far. -

@lia I really admire your work, amazing attention to detail!

How did you fabricate the aluminum top plate ? Looks like it was pressed out with dies. -

@lia said in Onewheel XS:

So far so good, no fire.

This would be the pre-pre-alpha test . . . Good job!! ! :D

-

@lemur Thanks :D

You nailed it, made 2x 3D printed plates to encase the 1mm thick sheet then over several repeated sessions of crushing it in the vice it got the shape from the dies. Once pressed I drilled through the guide holes then used a final template to cut them on the mitre saw.

Controller was easy enough since I made that one correct to scale so it's barely raised. Battery side though I gave myself 3mm extra to work with since those cells stand no chance otherwise.

@OneDanGT Aha true xD Honestly was shocked nothing went pop like the caps.

-

@lia That's great engineering!

-

Oh, my god, is being a long time since I haven't seen that thread.

Lia, you are completely crazy!! You made it work!

So time consuming... this is just too much... Is not that I don't value what you did, which is superb. But your abilities deserved something you could ride ;) -

@ed_co Oh I'll totally ride it if not just for the humour of it :)

Just have to find the drive and brain power to figure out where to go next to finish it. The programming side and hooking up the gyro is daunting but is really the next step I should be taking.

-

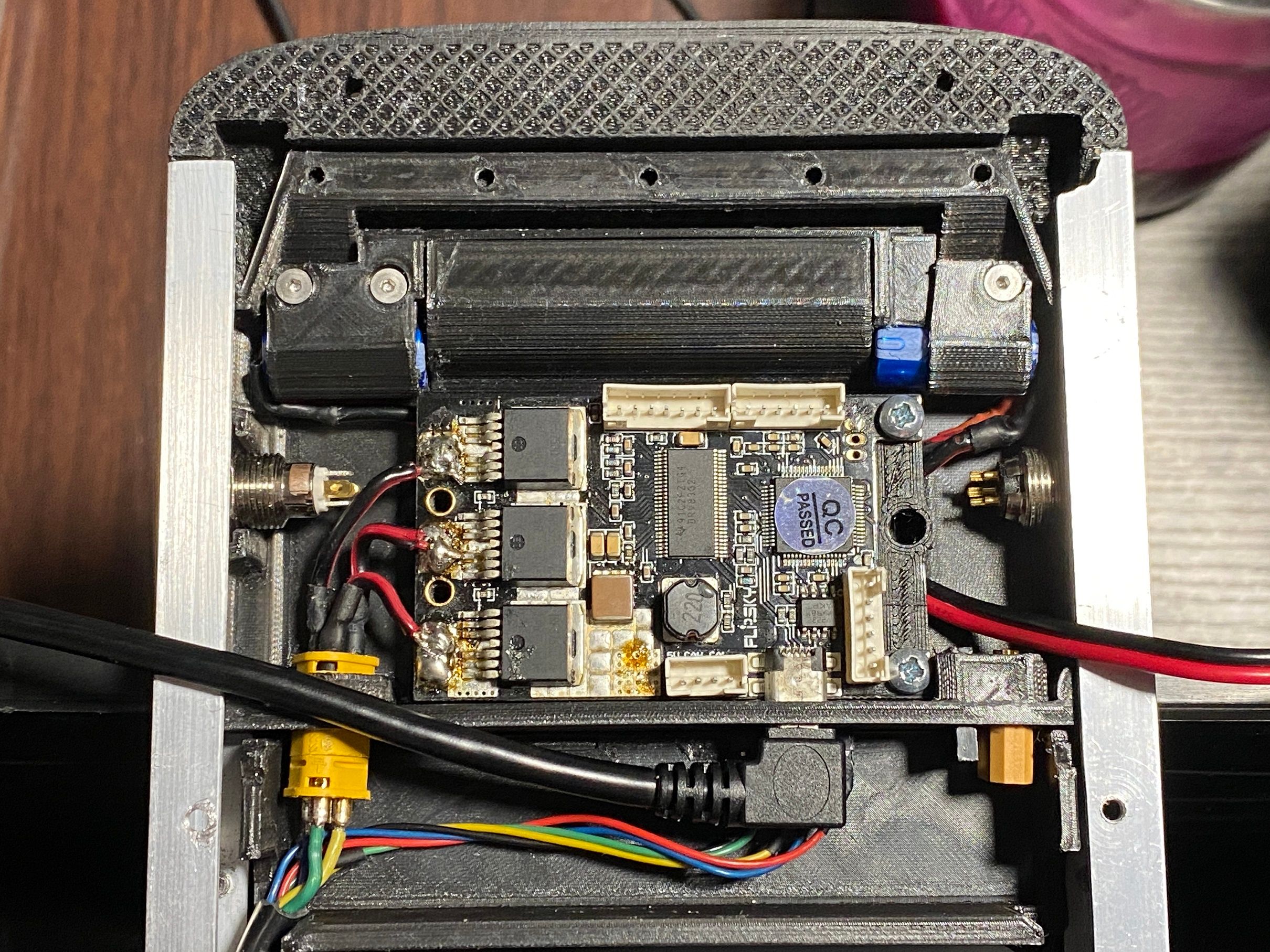

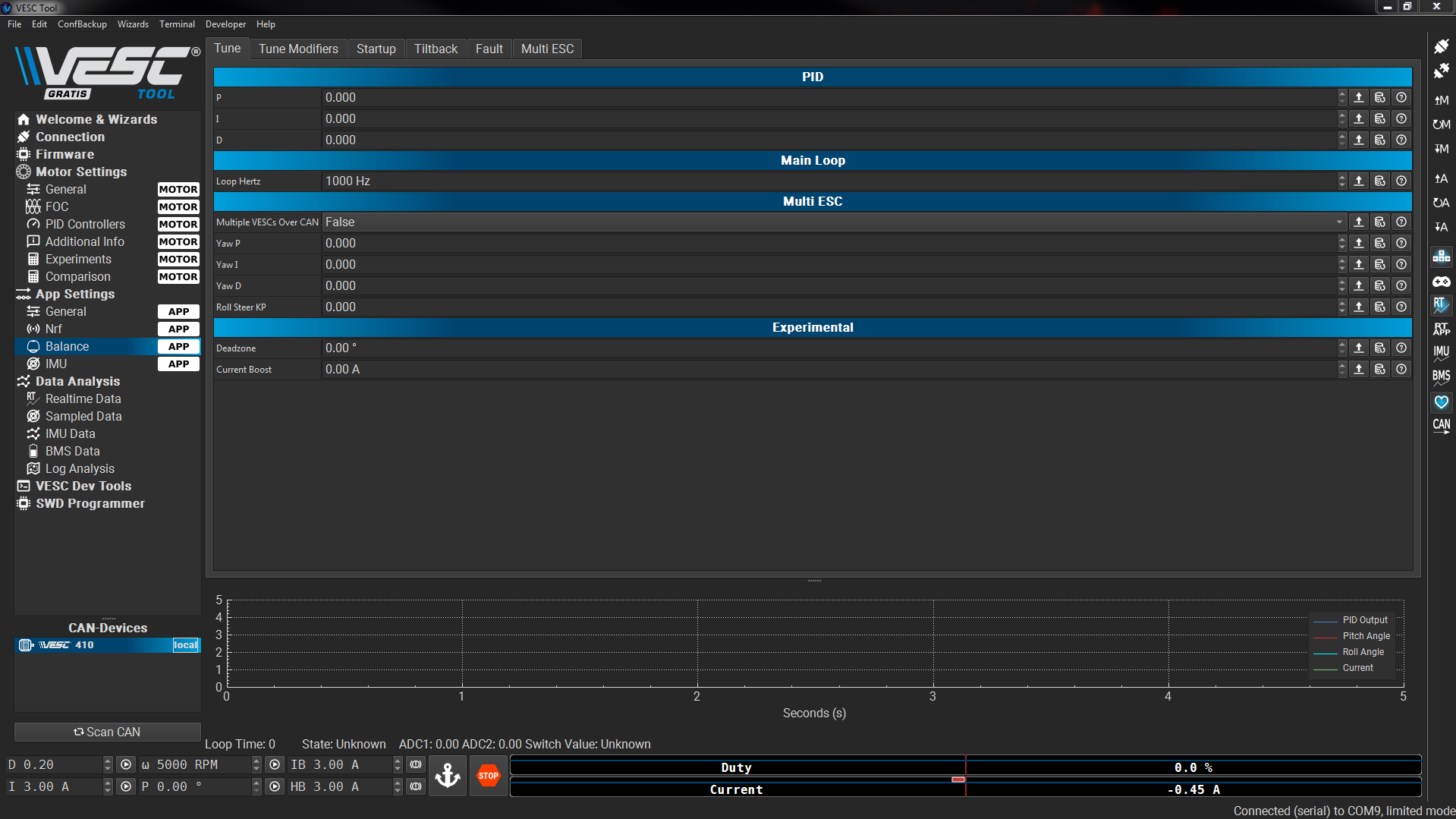

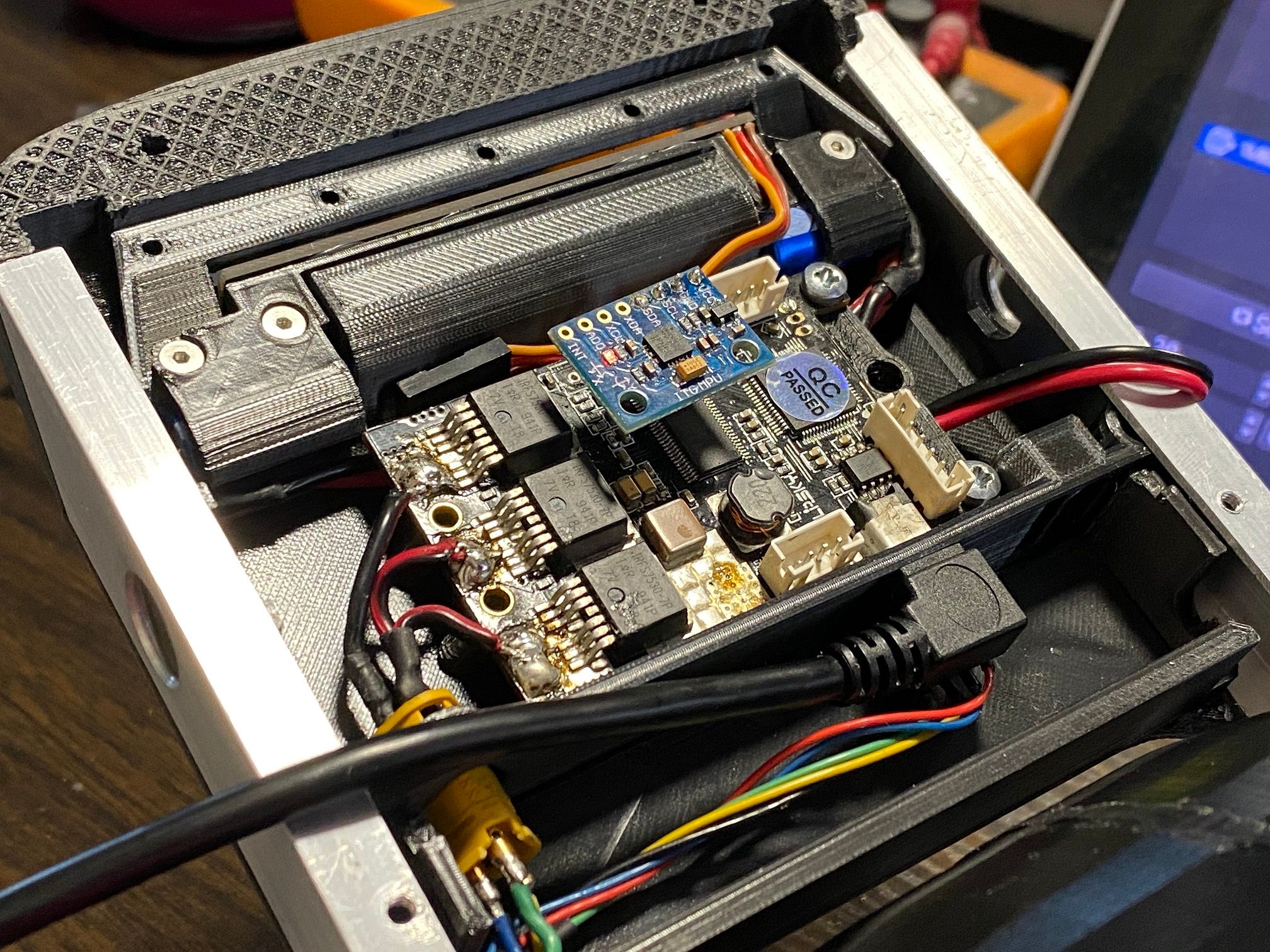

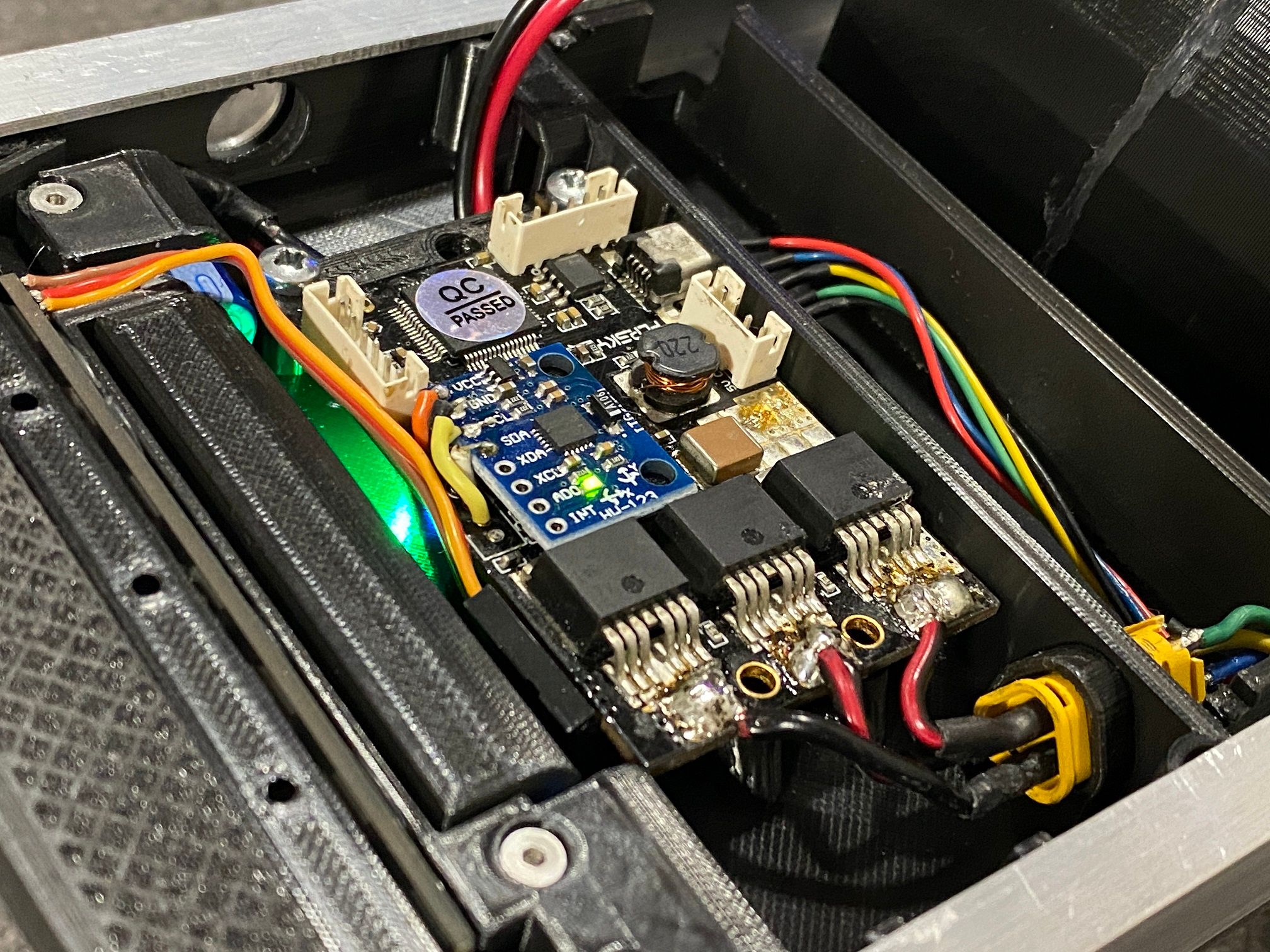

Wanted to get the gyro wired up but hit a snag where connecting it drops my usb connection to the VESC. Ignoring the Arduino and passing the gyro data straight into the FSESC to interpret since it has it's own balance app built into the VESC tool :)

I'm probably wiring it up wrong since the pinout for RX/TX on my FSESC seems to vary a little depending on whose documentation I'm looking at.

So in the meantime I've reprinted the controller housing to accommodate the LED bar a bit better.

Love seeing this thing move so decided to dangle the USB cable over and took it for it's first float. Still hooked up to external power of course. Last thing I want is to have a fault that sets 4 cells on fire D:

Motion is super rigid because the keyboard controls are full backward, -1mph , +2mph and full forward (under current restrictions programmed for now).

Still pleased with the amount of torque shown without even touching a single amp (I should be allowed up to 30A burst and 20A continuous).

Once I get the gyro hooked up I'll look at doing a balance test with my hands before working on making it structurally solid enough to definitely hold my weight.

-

@lia Hilariously awesome watching the baby learn to float!

-

@onedangt IKR. So adorable watching it flop around.

You can tell which side I biased the cells in the battery housing by how it naturally wants to turn left. -

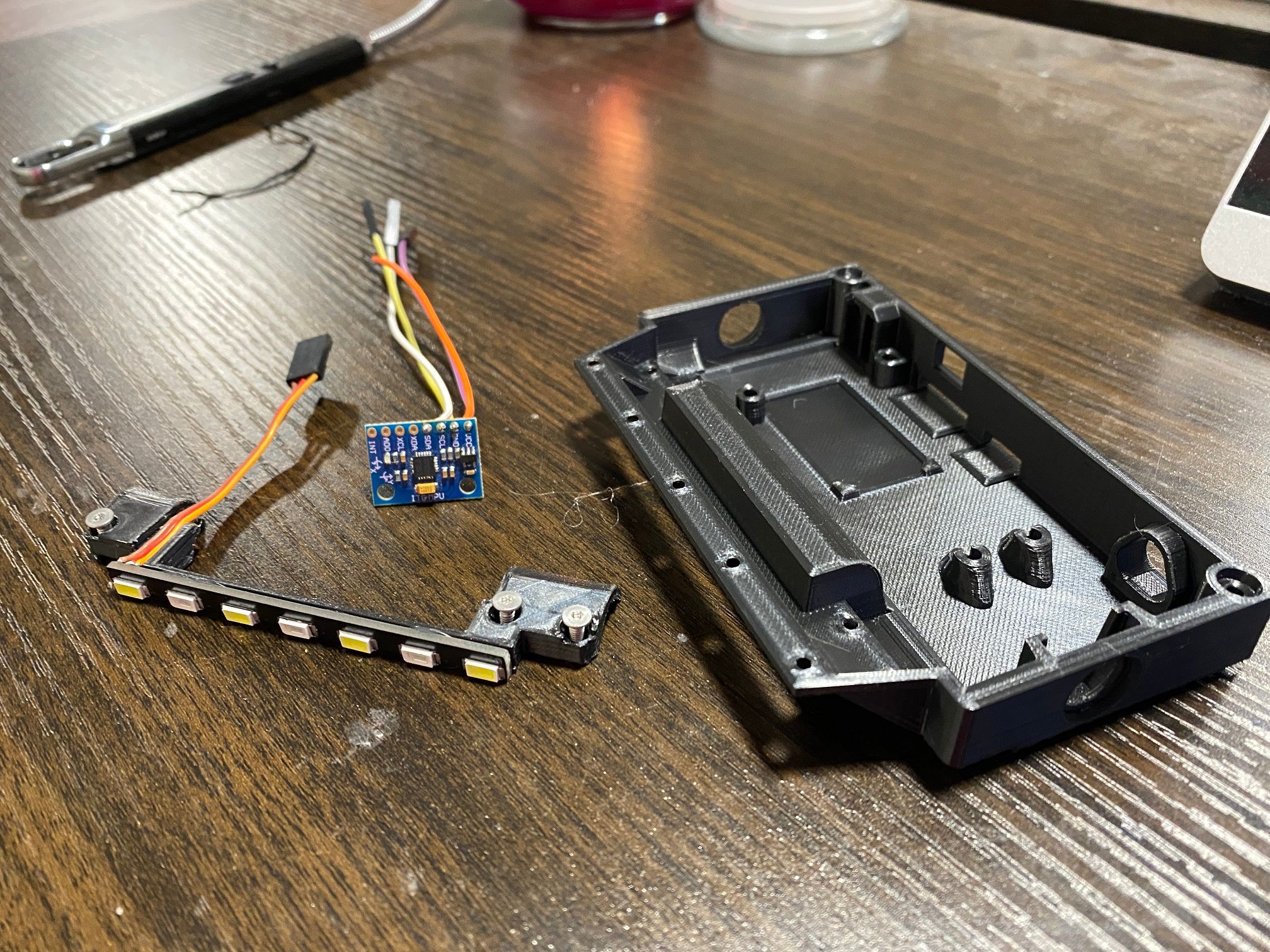

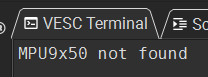

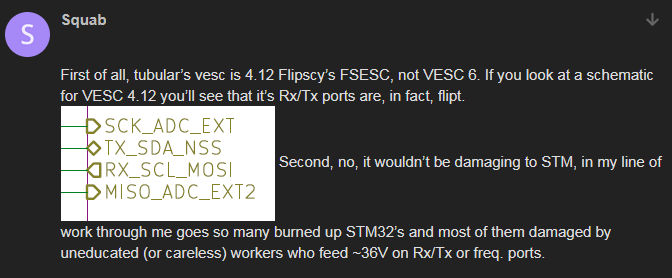

Got the IMU hooked up "properly". Soldered it directly to eliminate any dodgy data. However the VESC still cannot communicate over the I2C line (SDL/SDA) to the IMU.

Not sure if it's just bust or I'm missing something so will try testing it on a spare Arduino another day to verify.

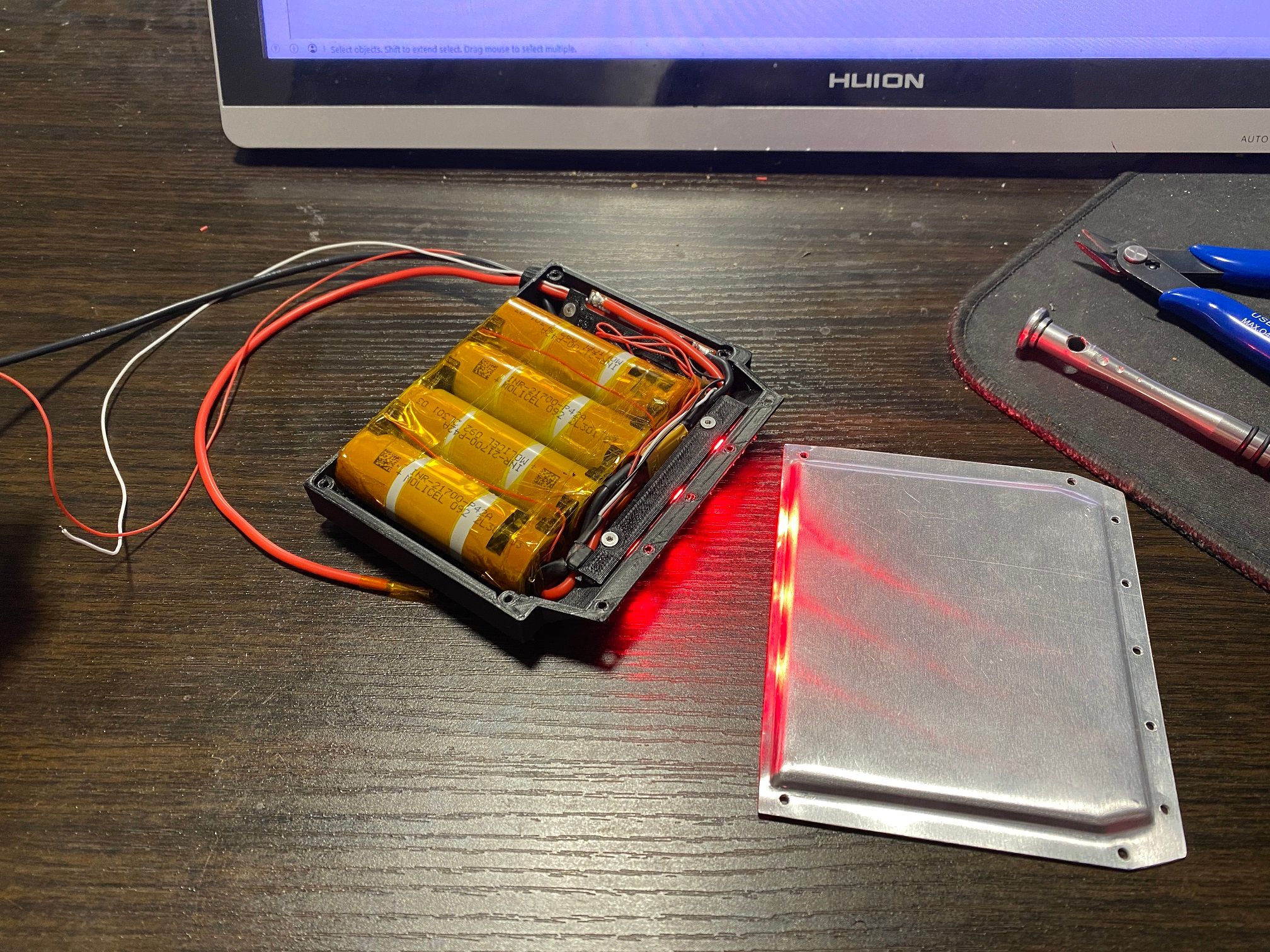

Also thanks to the housing redesign the LEDs fit nicely now.

Will have to find a way to control them still, might still use an Arduino to read the hall wires from the motor to change the lights. Will need an external mosfet to control that since the tiny Arduino I have will fry if I try to power them off it. Already tight for space and still need to implement a power circuit to toggle power depending on the button's state up in the controller. I'll likely put that near the BMS since there is some room there and makes sense.

Learnt a bunch from fiddling so far although my squishy head hasn't made complete sense of

anymost of it. Updated the firmware and now most of the balance config is available. Also swapping the "App To Use" setting to enable balance settings causes the manual keyboard controls to act real weird, thought I busted the settings at first.After adjusting limits though it runs smother still without being secured properly.

.

Edit : Looks like my little MPU-6050 is dead, wild since I've had it sitting unused for like half a decade in my Arduino box. Used some test code and can't get it to spit out anything. Ordered a new one to come tomorrow :D

Edit 2 : New one showed up and worked straight away on the test bed so will look to plop it into the XS tonight after I've finished melting from today's ride.

-

They said it couldn't be done!

This is with P=1 I=0 D=0 for now.

Saw suggestions on the full scale to have P at 25 but when I tried that it attempted to take off before hitting the duty limit moments shy of screaming off the table.But wait there's more... I have invented Ghosting+

And this is with extremely limited "don't catch fire" settings. I still have to tune it! (and have it run off the internal battery)

Took longer than expected. Wired up the new MPU aaaaaand nothing. Turns out after an hour of googling I came across this gem.

https://electric-skateboard.builders/t/onewheel-build-guide/80129/449

THE DAMN PINS ARE REVERSED REEEEEEEE

After swapping those it worked. I did that on my old one but it was totally broke and didn't think to try on the new one >.>

Sandwiching the IMU between a connector and mosfet is probably fine right? I added electrical tape to the bottom afterall which is the electrical equivalent of hiding under the sheets so the monster can't get you.Next up is building some footpads (that don't ghost). The 40x40 FSR's go for about £12 each which kinda sucks but if I want this done I'll have to buy them. It'll add a tremendous amount of rigidity to the whole thing and allow me to test ride it.

In the meantime since they might take a while to come I might look at hooking up the LEDs.

I definitely need to redo the tire. That TPU does not grip to anything well enough. Guess casting rubber might be my next best bet. Print a tire in PLA, make a mold around it then cast into the mold. Printing a mold makes sanding more difficult as I discovered prior to the TPU tire.

-

Seat belt/air bag occupancy sensors would likely be the cheapest foot pad sensor option. Short of build your own with alum-in-um foil and silicone to give sensor separation to prevent ghosting.

-

@samuraipunch I do have some of those car seat sensors recommended to me by @ed_co for a full sized pad but I'd need to cut them up to fit this 1/2 scale pad.

.

Edit 1 : Did some testing with the LEDs. Built the rear bar and found some PNP transistors that I could use to power these. Would use NPN but I used a common ground making it impossible without redoing the lightbars.

Also here's the power button using the same fade animation to test.

I'll need to build a little 3xPnP transistor board to power this lot. 1 for forward, 1 for reverse and 1 for the power button :)

.

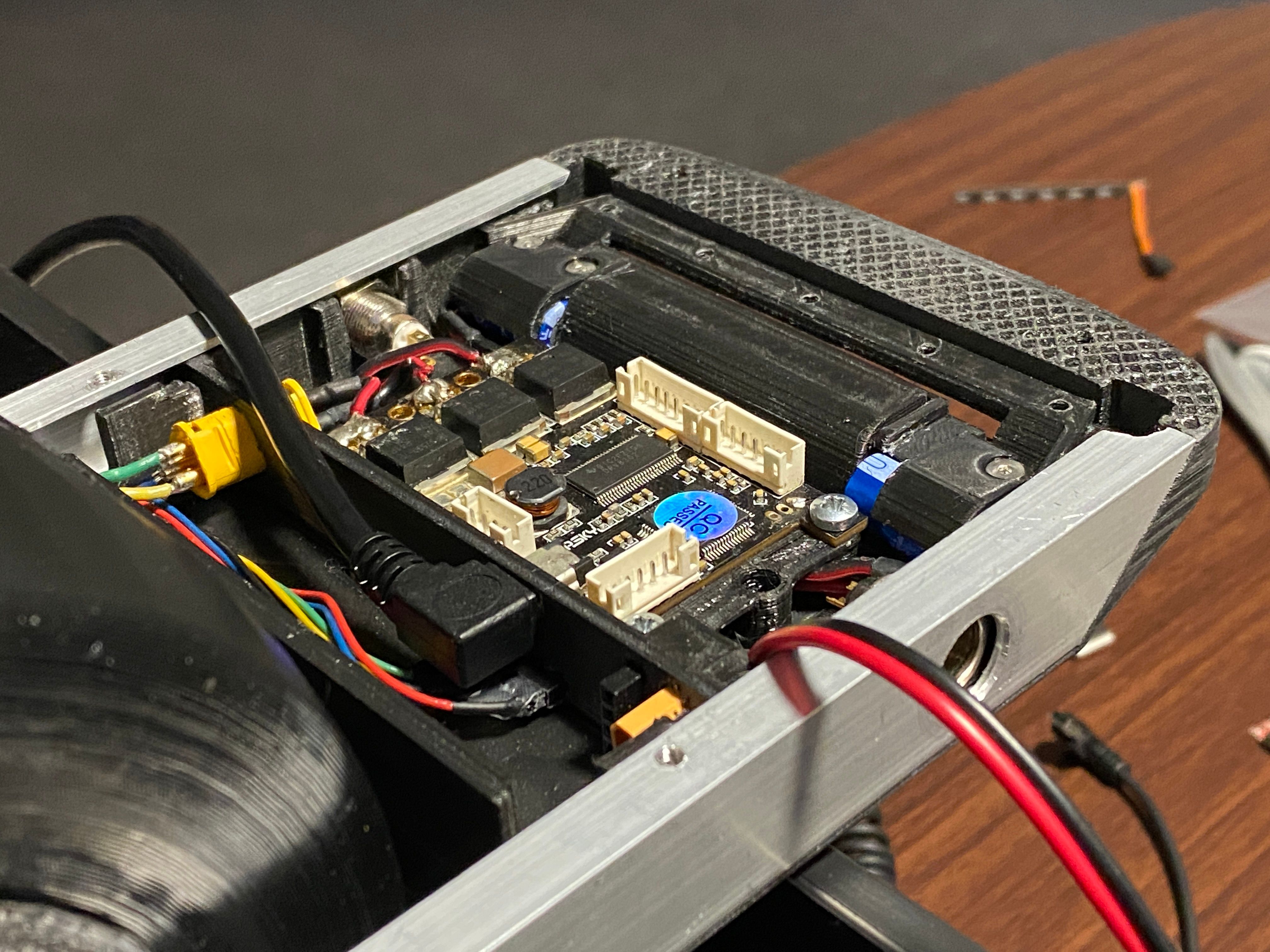

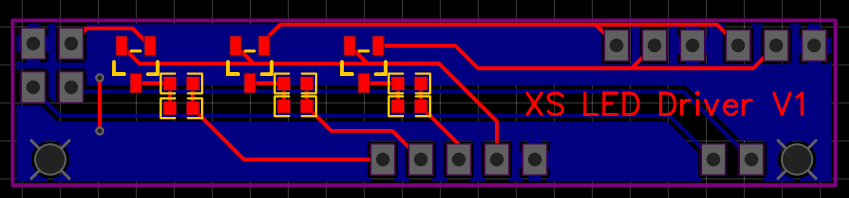

Edit 2 : Designed a small PCB to drive the LEDS from the Arduino Pro Mini tucked under the FSESC. Getting real dense in this controller box. Will need to also run split connections off the hall sensors wires into the Arduino to figure out the rotation to change the lights but that's for another day.

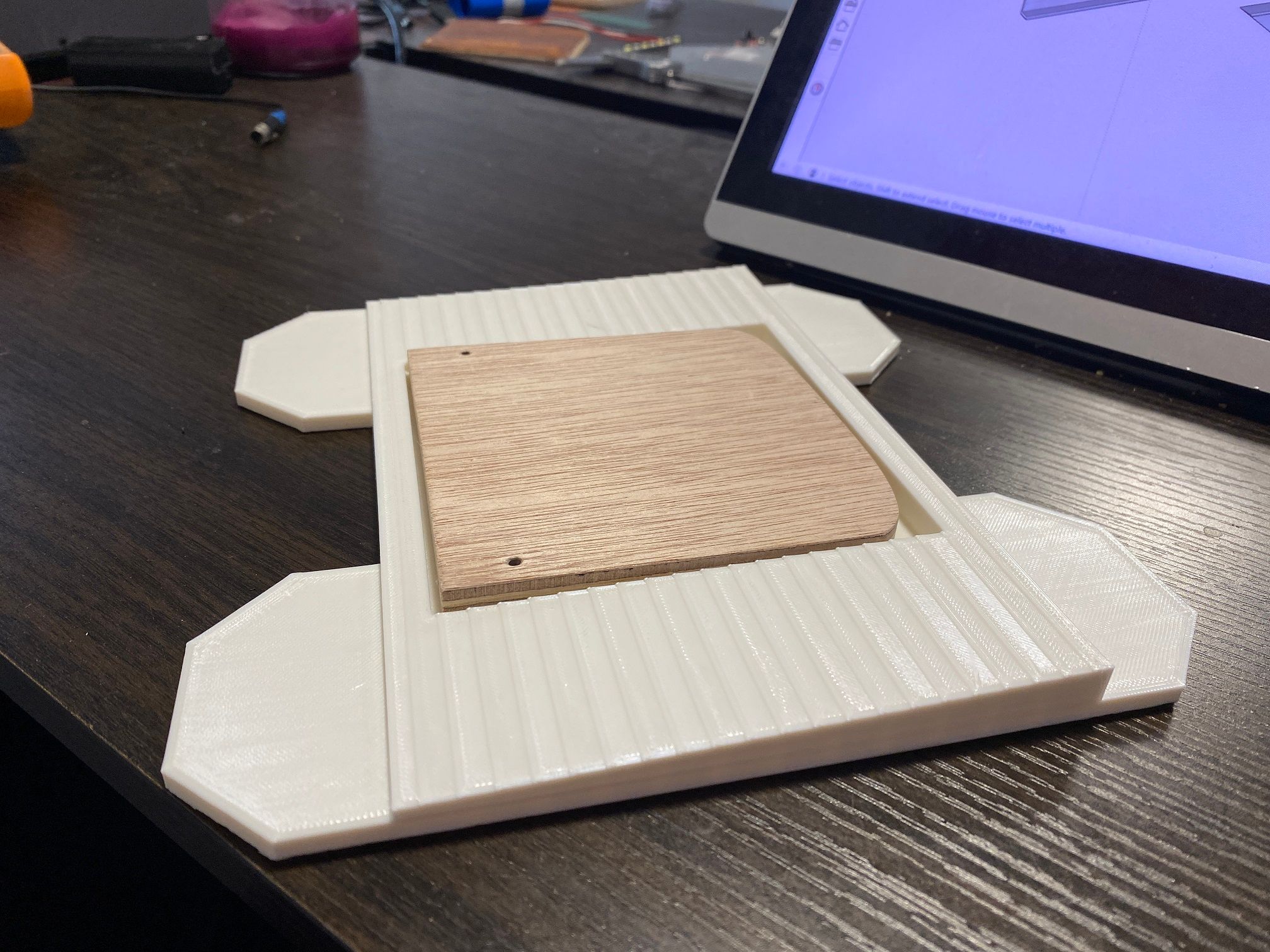

Also I printed a half scale stand ;)

.

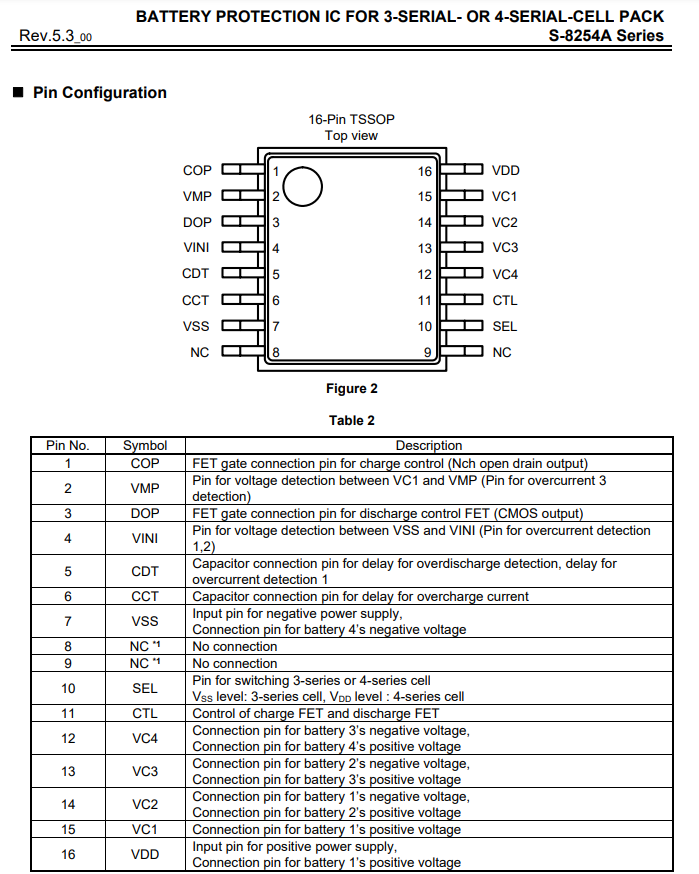

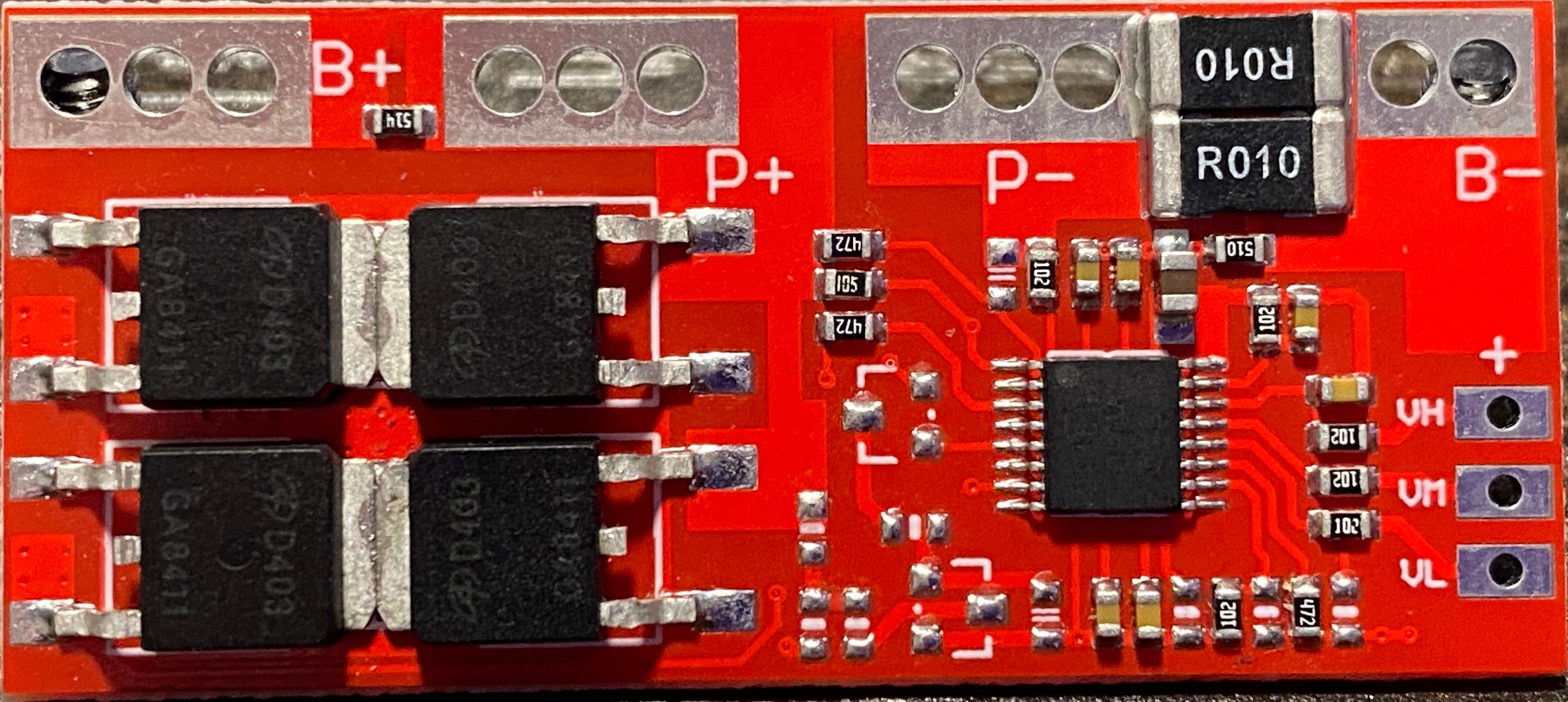

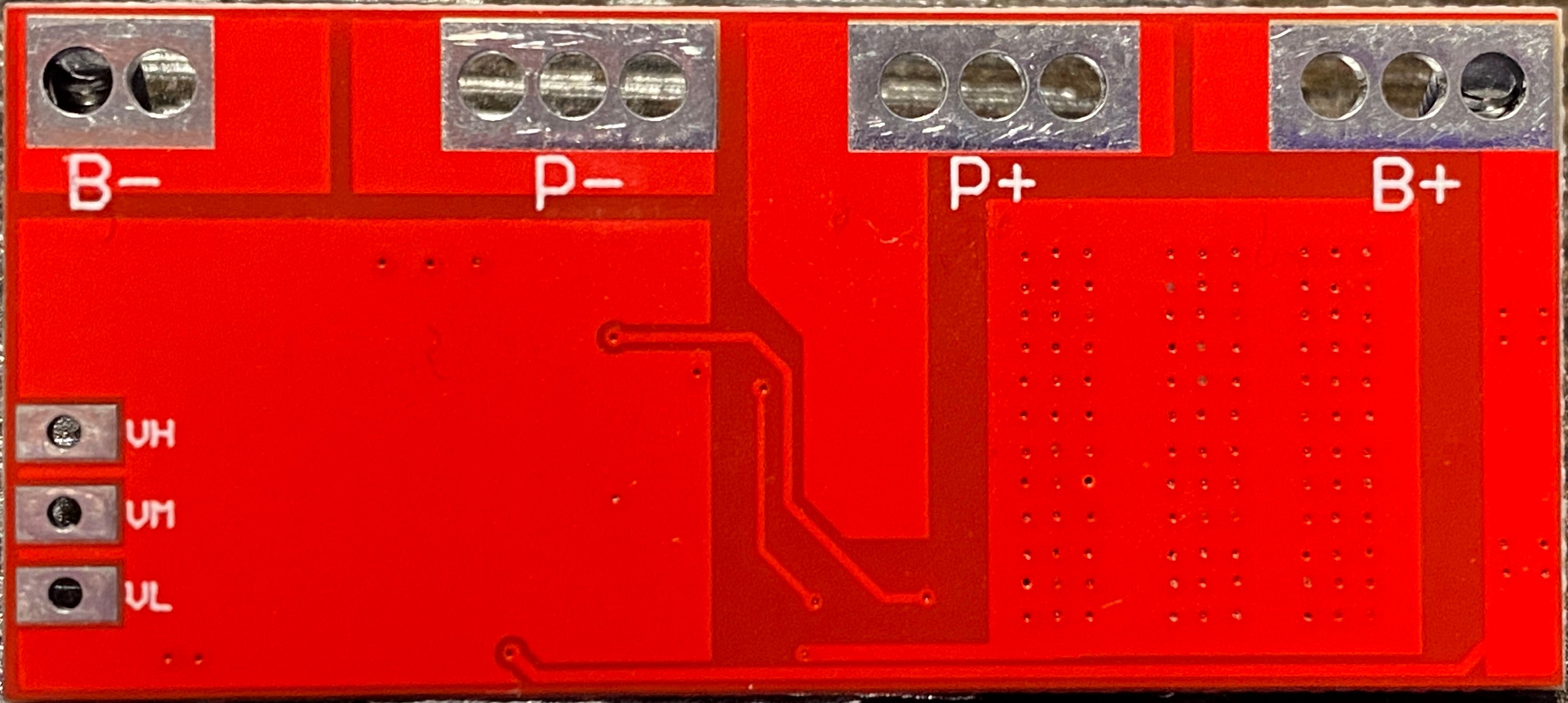

Edit 3 : I think I found a simple way to add a switch to the BMS without using external mosfets.

Wanted to use the fets on the BMS but couldn't figure out what I might need to do. Found the datasheet for the protection IC and think I might be able to simple cut the trace leading off pin 3 and run the switch wires between them.https://www.ablic.com/en/doc/datasheet/battery_protection/S8254A_E.pdf

Pin 11 also controls all apparently but I don't want to require the switch to be on to charge.

Not sure if this will work as I intend, after lots of research plenty have wondered about adding switches to larger BMS's and most seem to give up, use an anti-spark circuit or wire the switch into a thermistor to cause a fault and disable it. None that I can find toy with just intercepting the gate for the output fets. I can only assume for good reason but I want to see if it will work :)

-

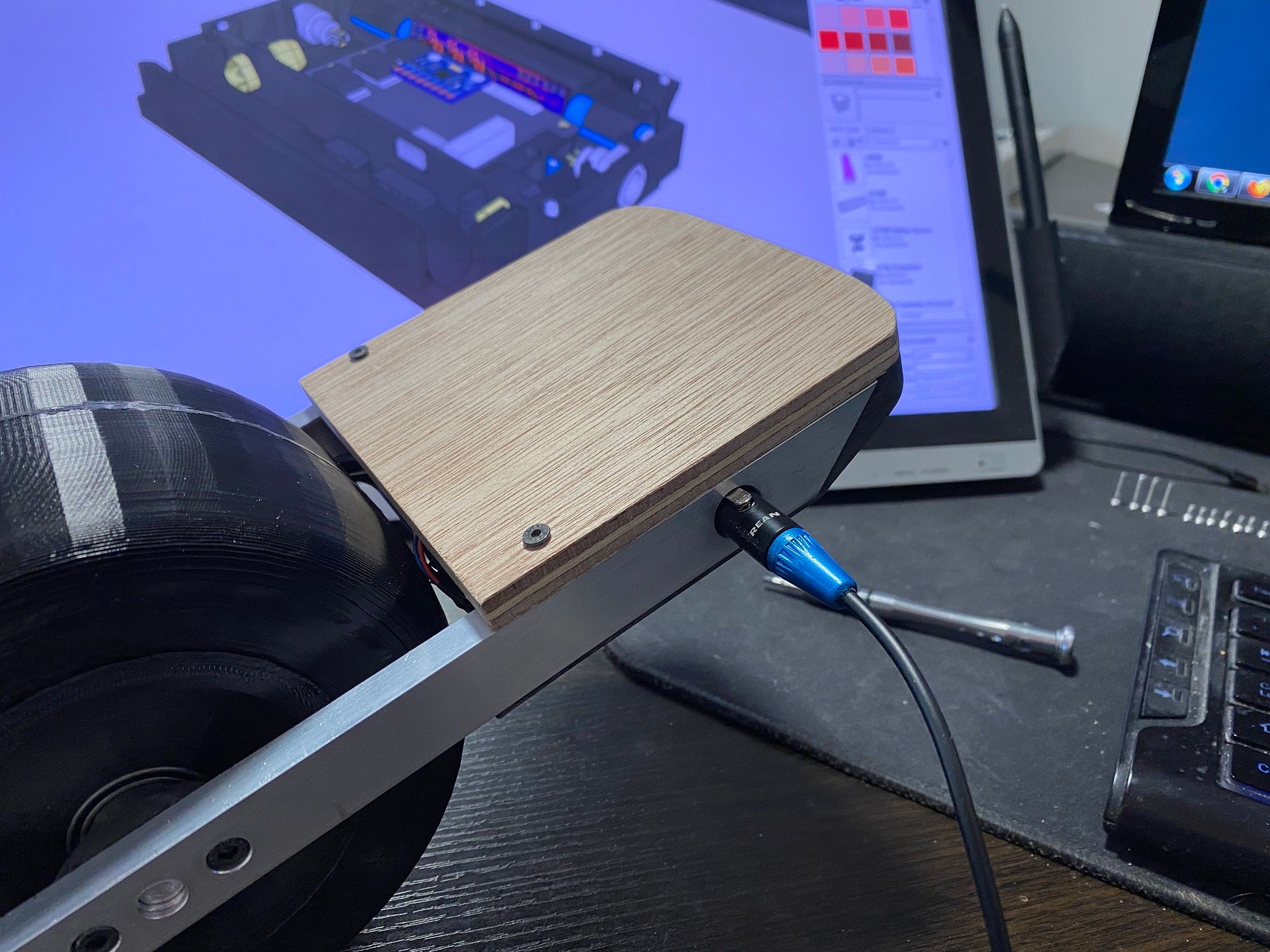

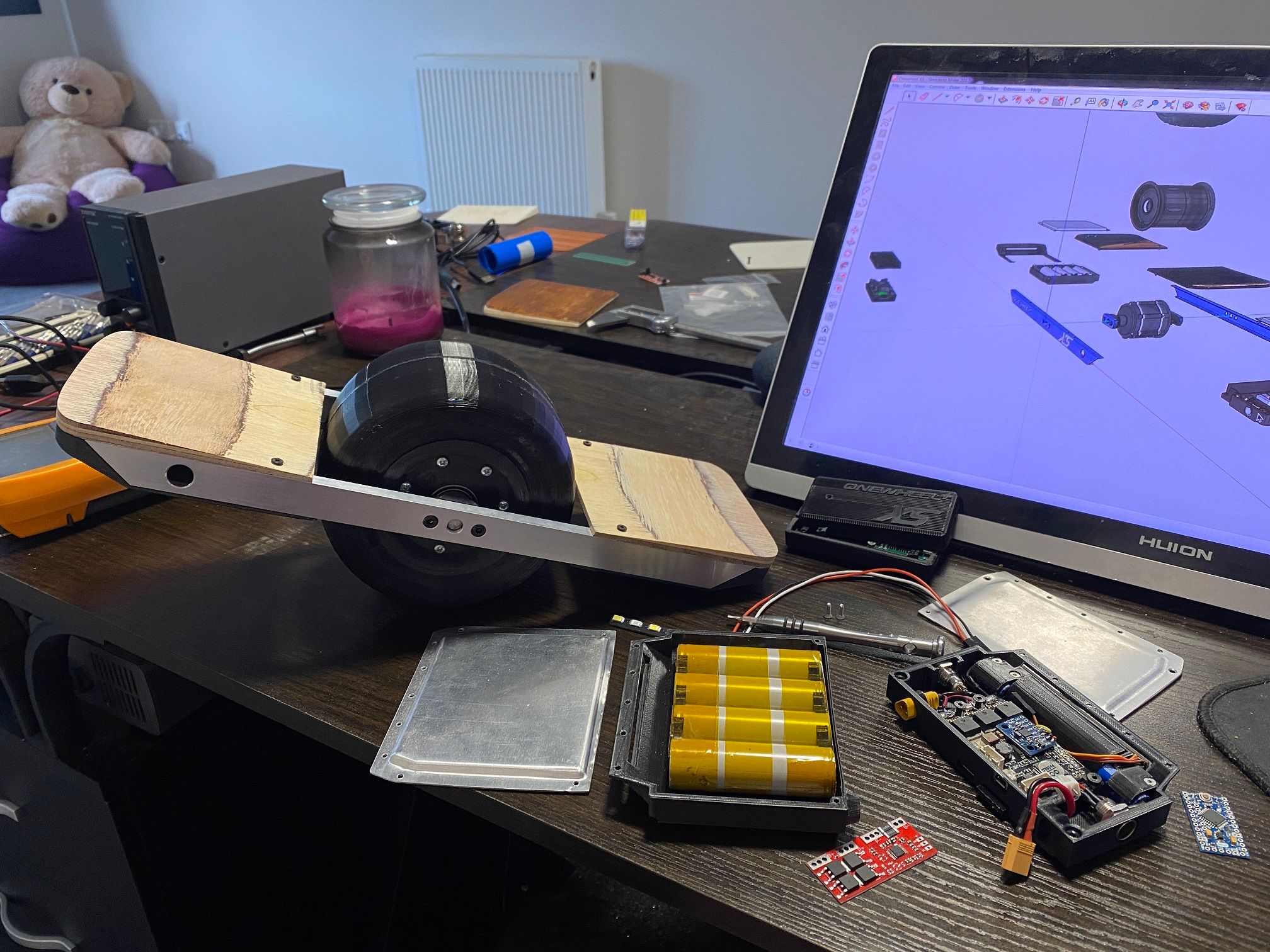

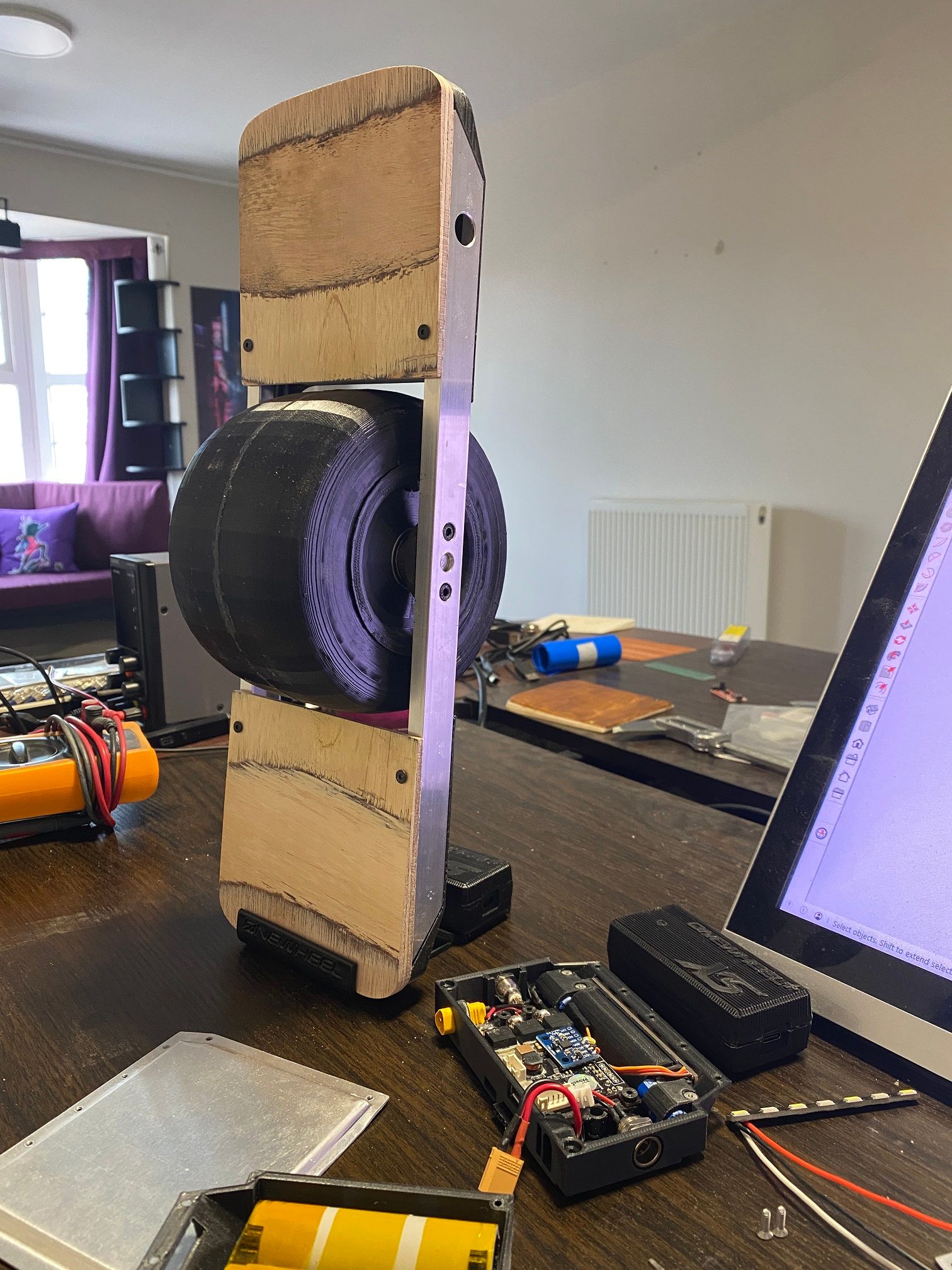

Finally had enough progress to share an update on this.

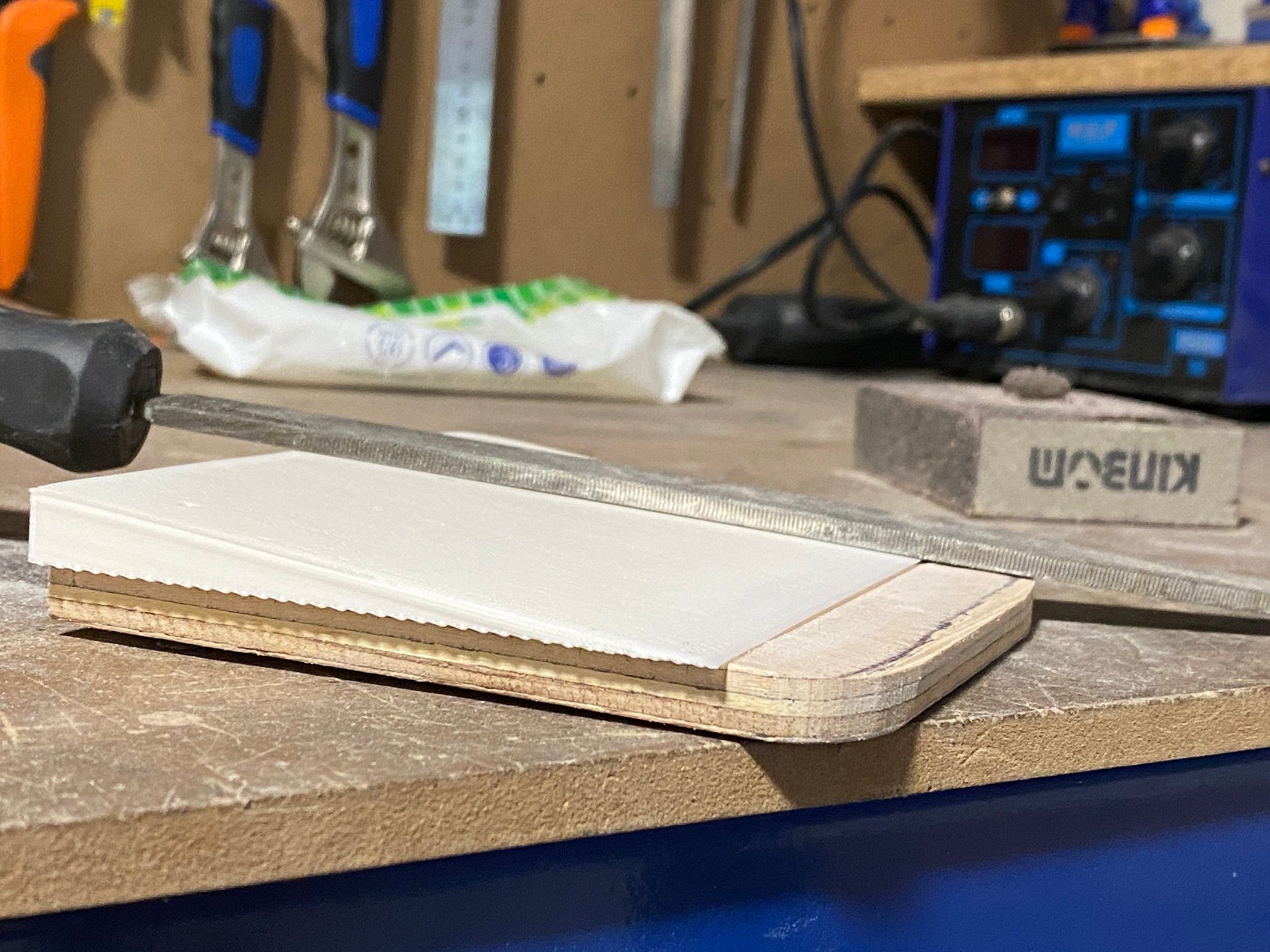

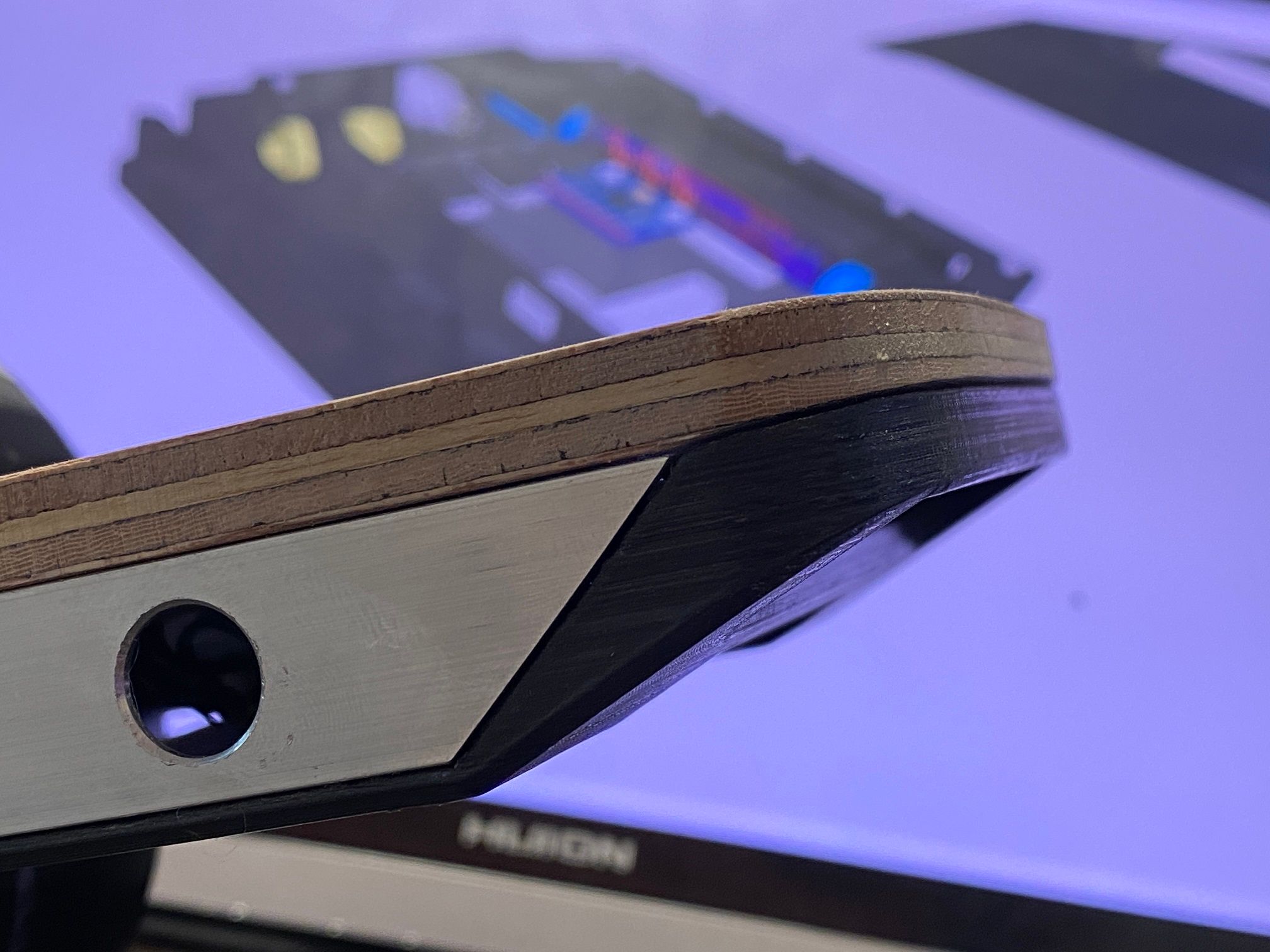

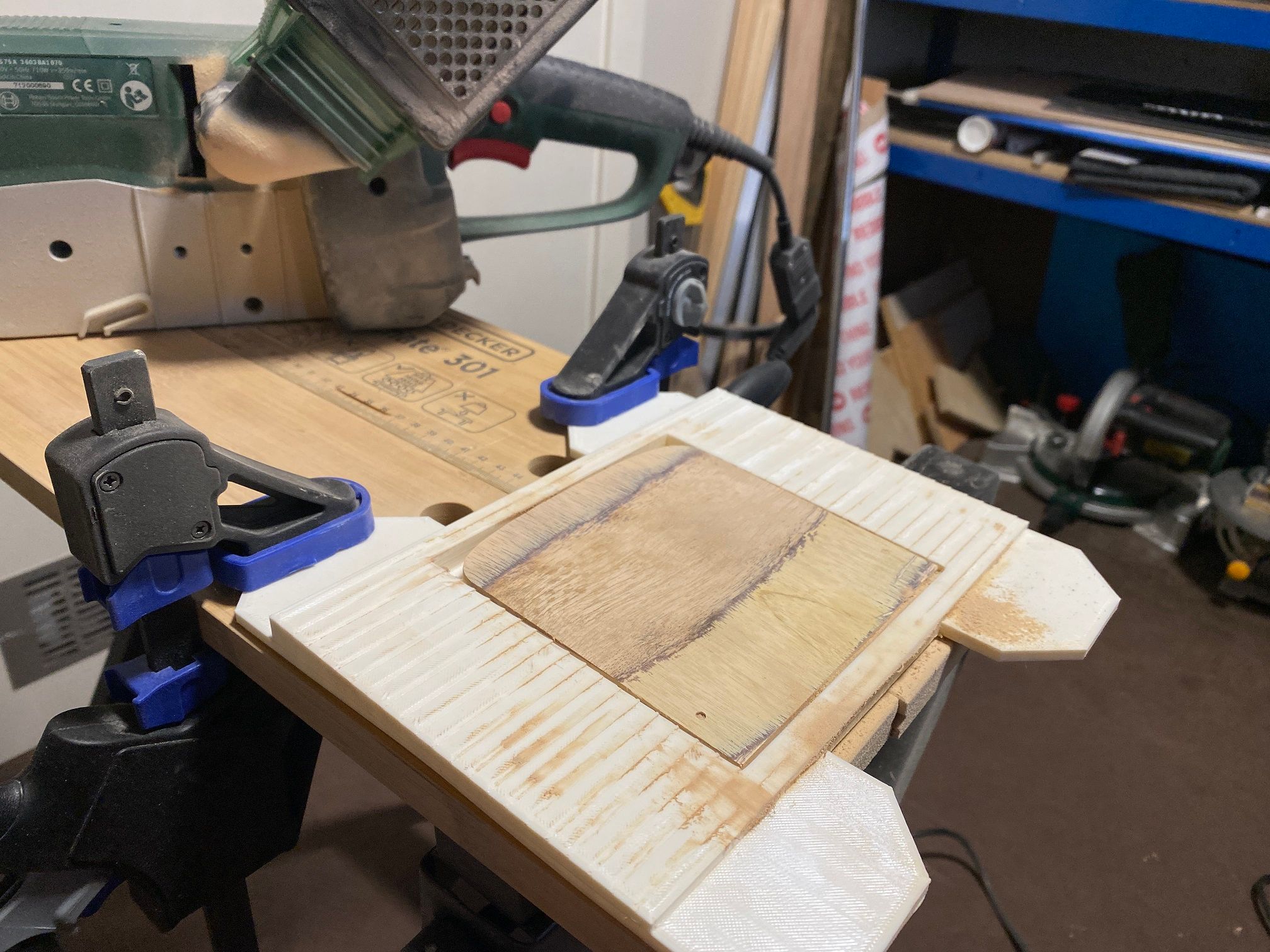

Nearly finished those footpads. Cut out 2 new chunks of wood and made a bunch of jigs to get it right. Hardest part so far was routing out the rear pad to accommodate the slightly taller battery housing.

Did one pass down to the first glue layer then another pass 0.5mm into the next wood layer. Took forever with my old Parkside rotary tool.

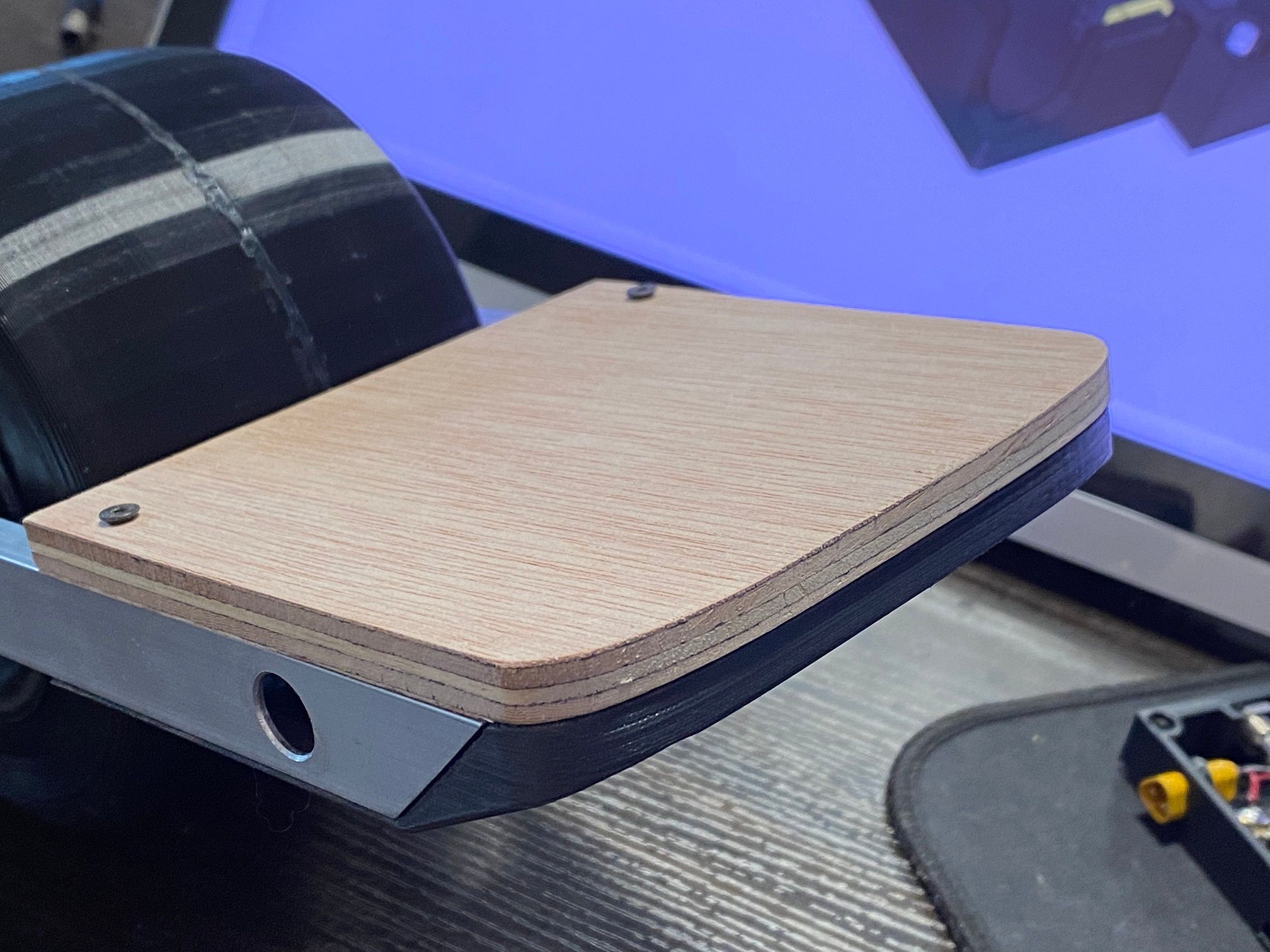

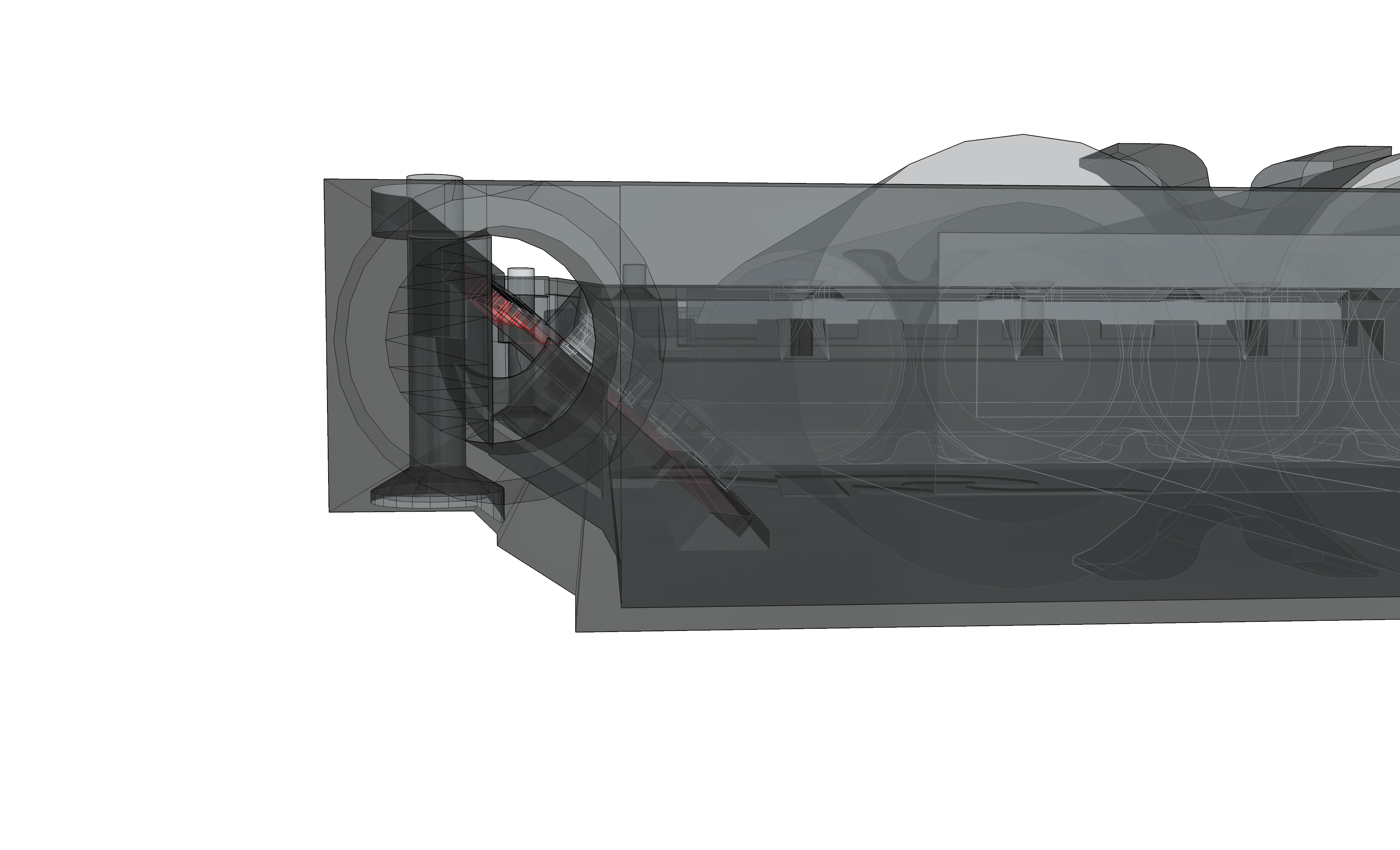

Came out good and left enough space to fit the lid. Here's an inside look without the battery housing inside the rails.

After that I removed some wood from the nose/tail ends where the bumper angles up a bit. I got it pretty close and can do a bit more to close the tiny gap left.

Will later angle the footpad, for now it's flat.

Curve is just a few more attempts at sanding away from perfection too :)

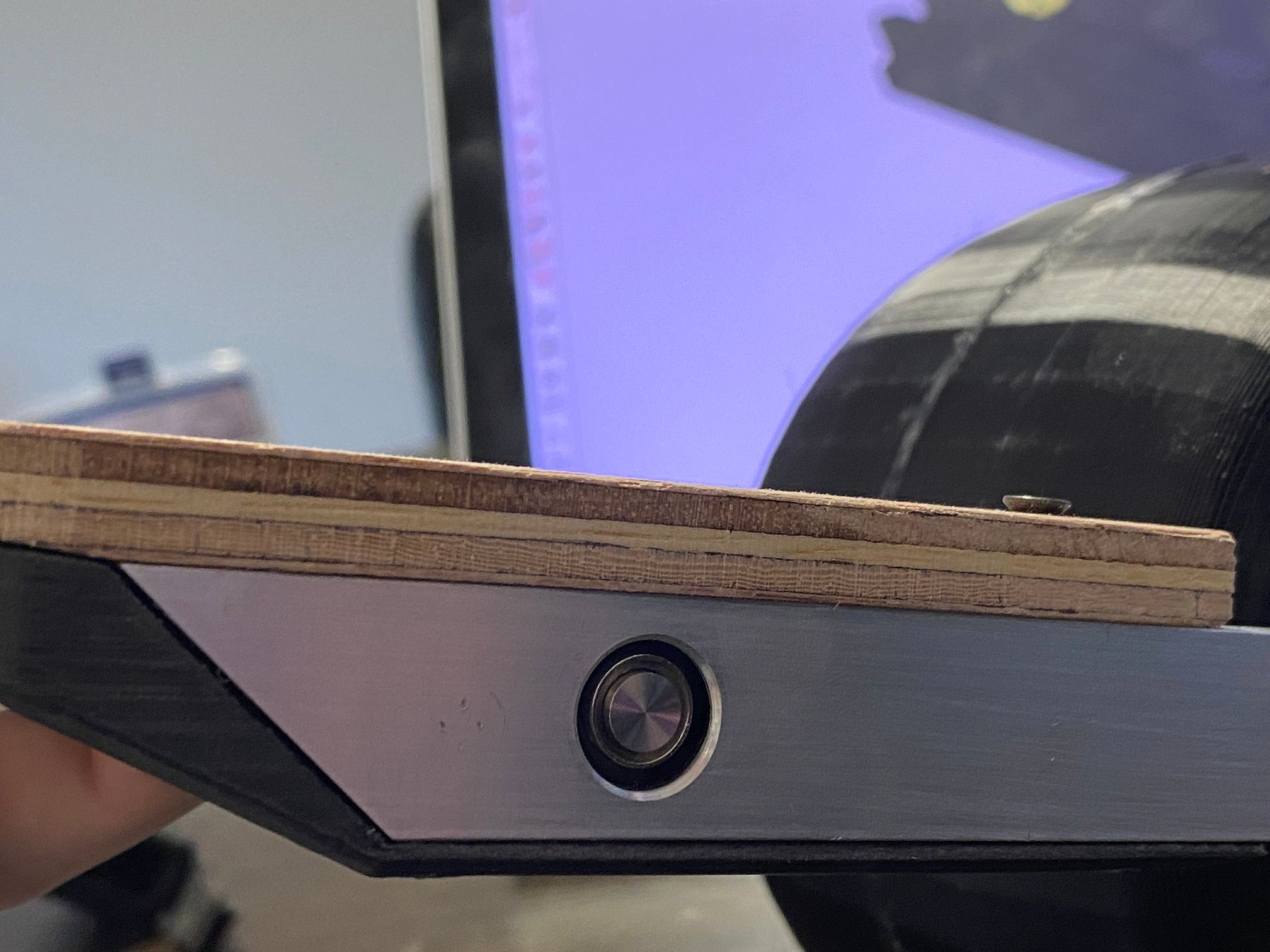

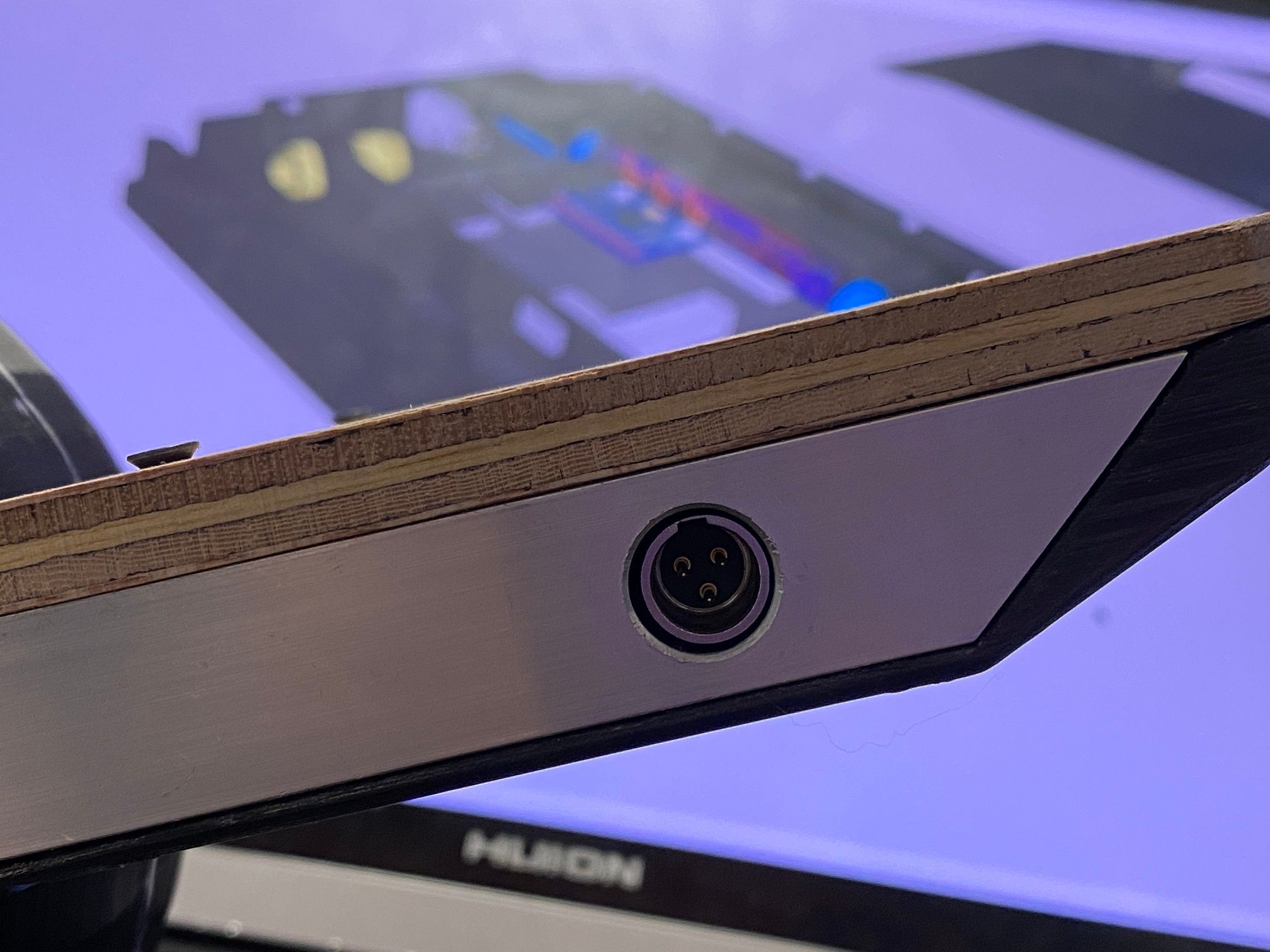

Ports still line up which is a relief too.

Left the jig to print last night that assists sanding down the footpad at the right angle.

Used my belt sander for this like time but instead of mounting the sander to the table and pressing the pad to it I did it the sensible way this time.

Came out clean :)

Waiting on some offcut veneer strips that I will make the top layer from instead of using varnish to fake it. Will also let me cut out some slots for the FSR sensors to sit in so they don't petrude too much and show through the griptape later.

Rear pad done too, had to be careful not to sand into the battery lid cavity for this one.

Last step for the sanding is to bevel the edges a bit, add the top layer and countersink the holes for the screws.

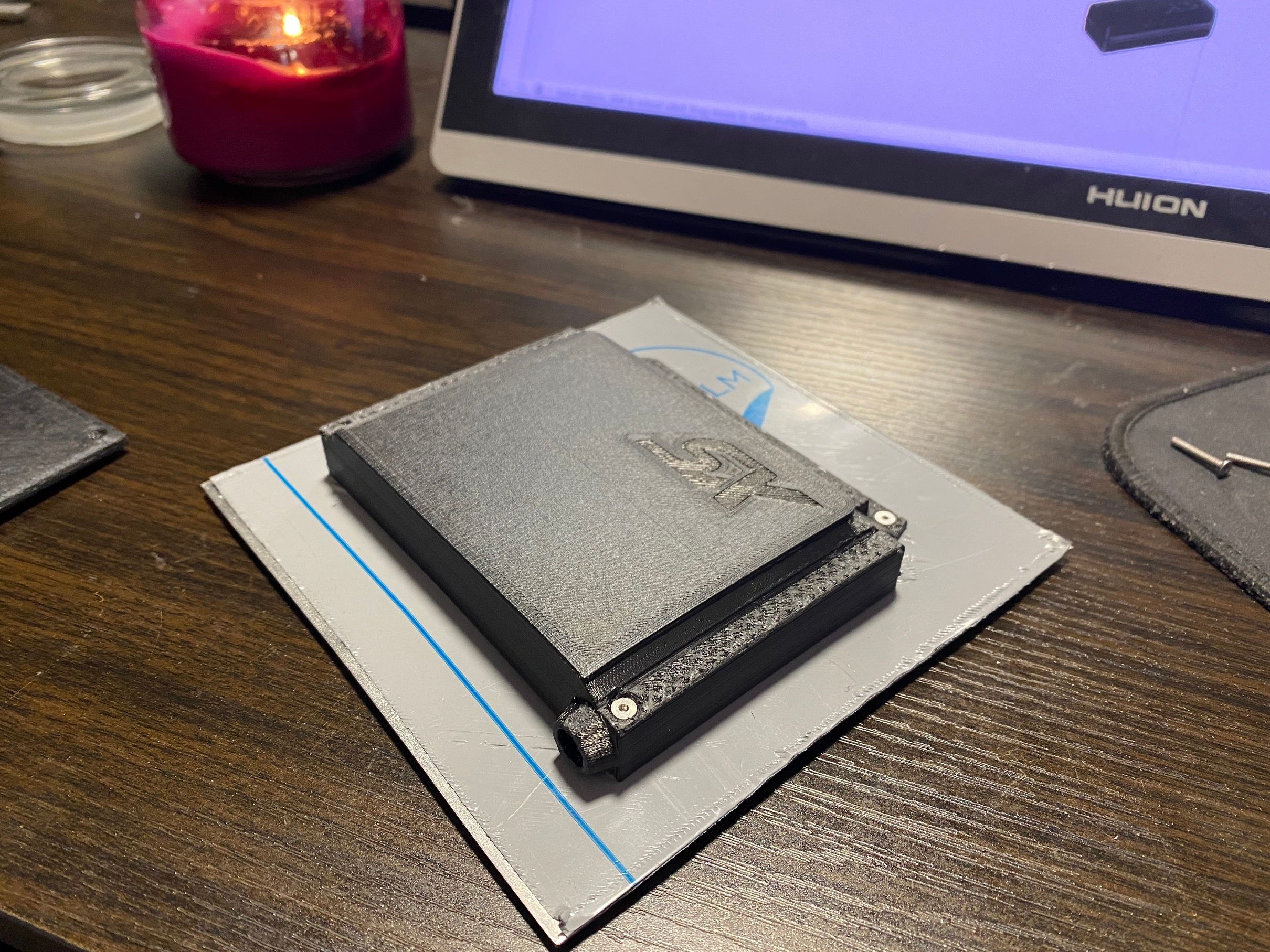

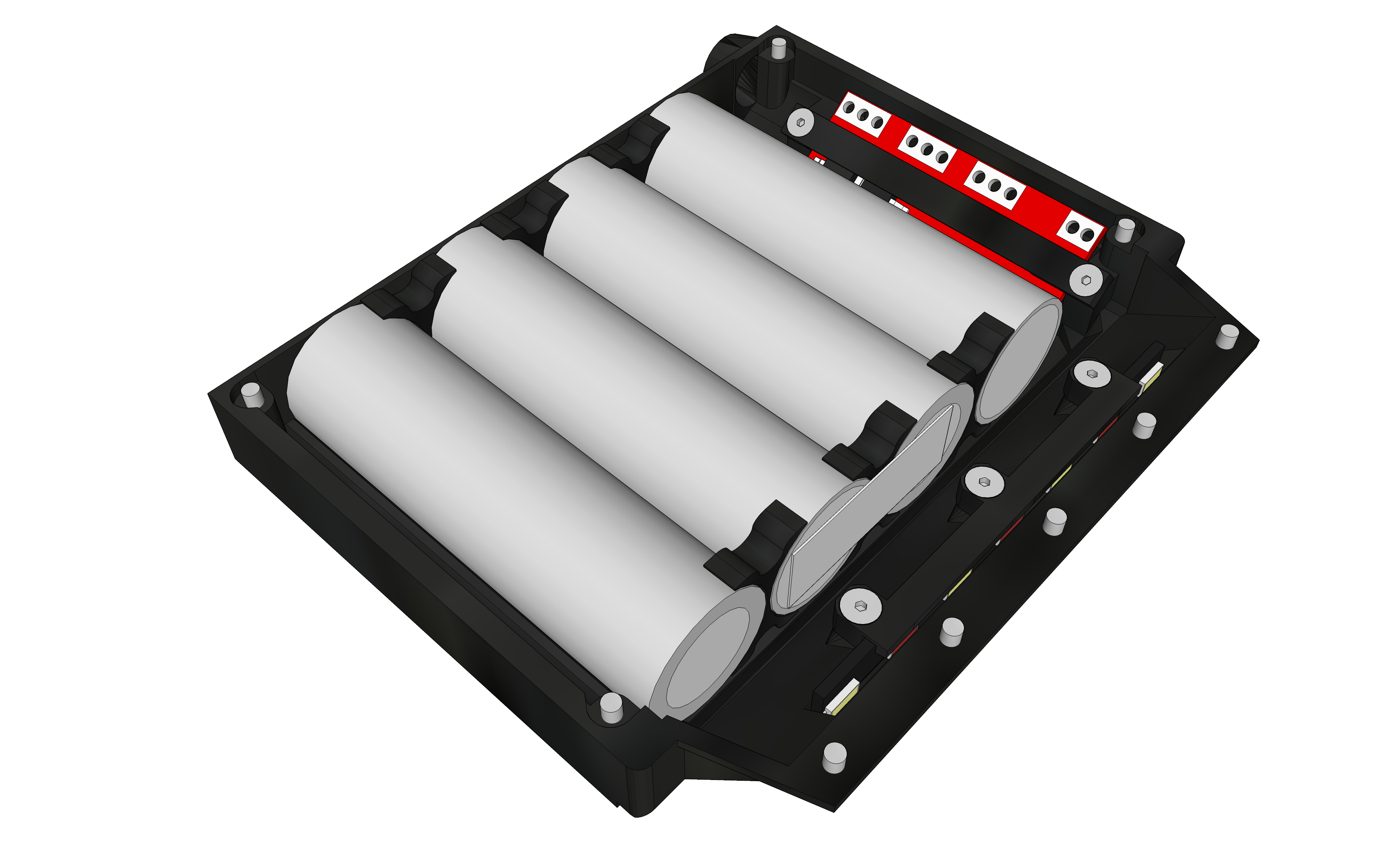

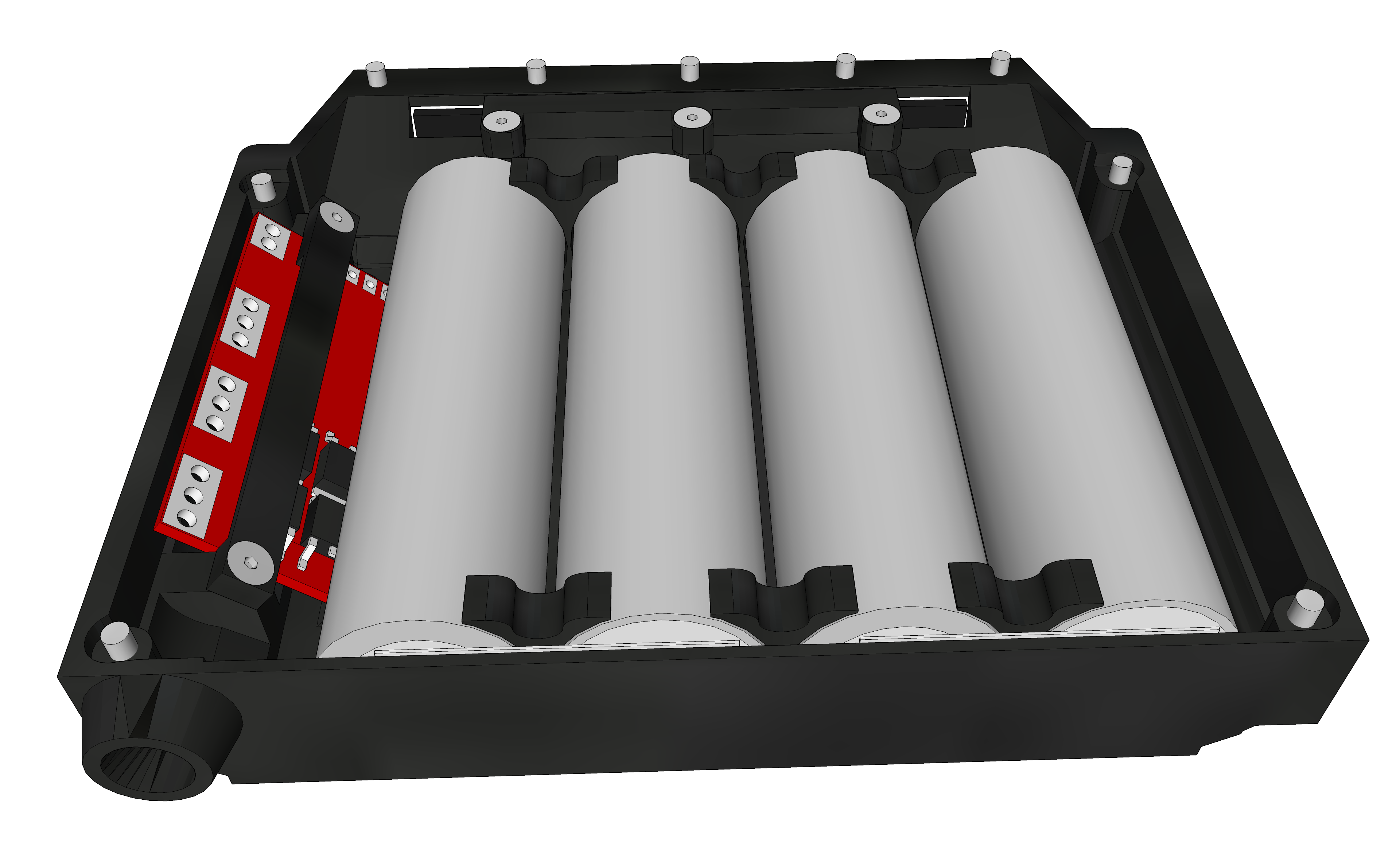

In the meantime I'm printing a new battery housing to fit the BMS properly and read light bar.

Not done yet so left the bits out on show :)

Also on a quiet period earlier in the week I printed a scale stand ;)

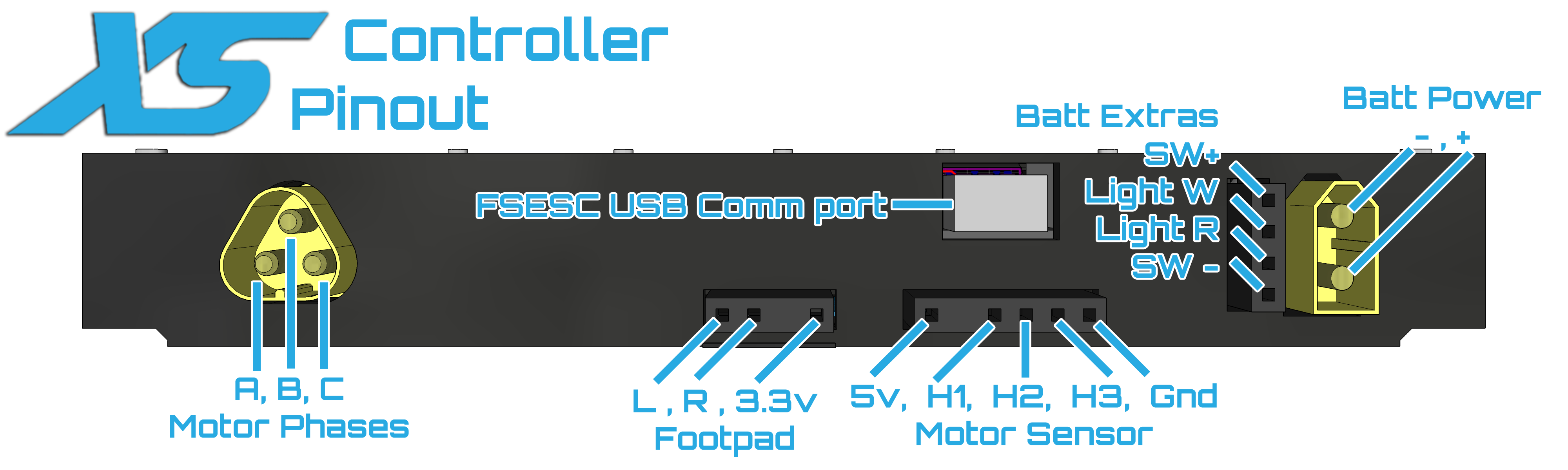

Here is the pinout so far for the ports on the controller.

The "Batt Extras" is wider this way so getting it backwards won't destroy anything but just reverse the lights on the tail. Gnd is shared on Batt - after checking those actually were on the same line so it'd actually work. Reason for this is there isn't room for another 5 pin connector so I can't put Gnd on it seperately or key it like the "Motor Sensor" and "Footpad" connector. -

@lia -- I am in awe of your perfectionism!

-

@s-leon At this point it's become something of an art piece much like that trophy I made for Dax which I spent much longer on than I expected.

As such I can't help but make everything just right. With all the jigs I've made making another shouldn't be as hard.

-

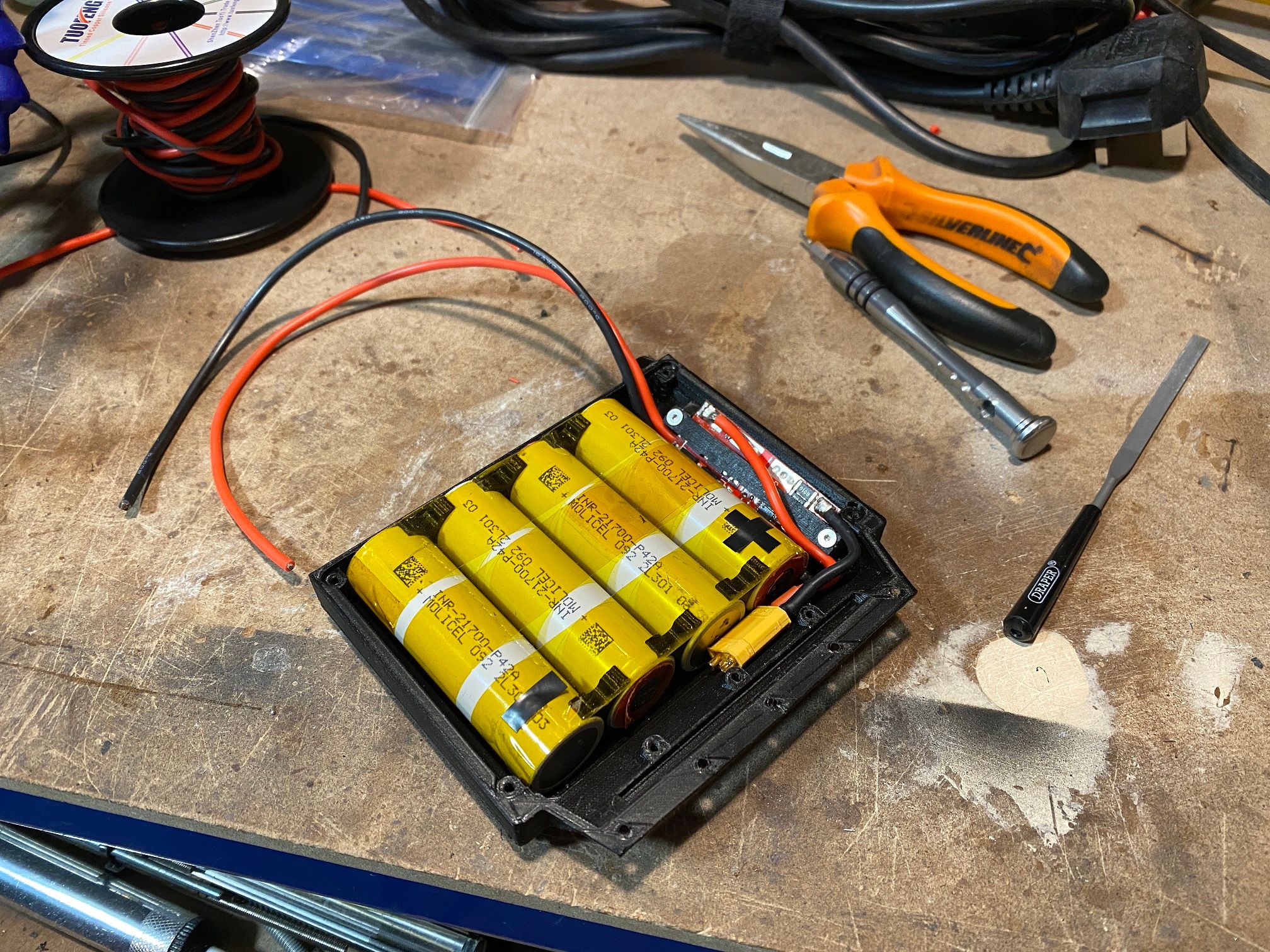

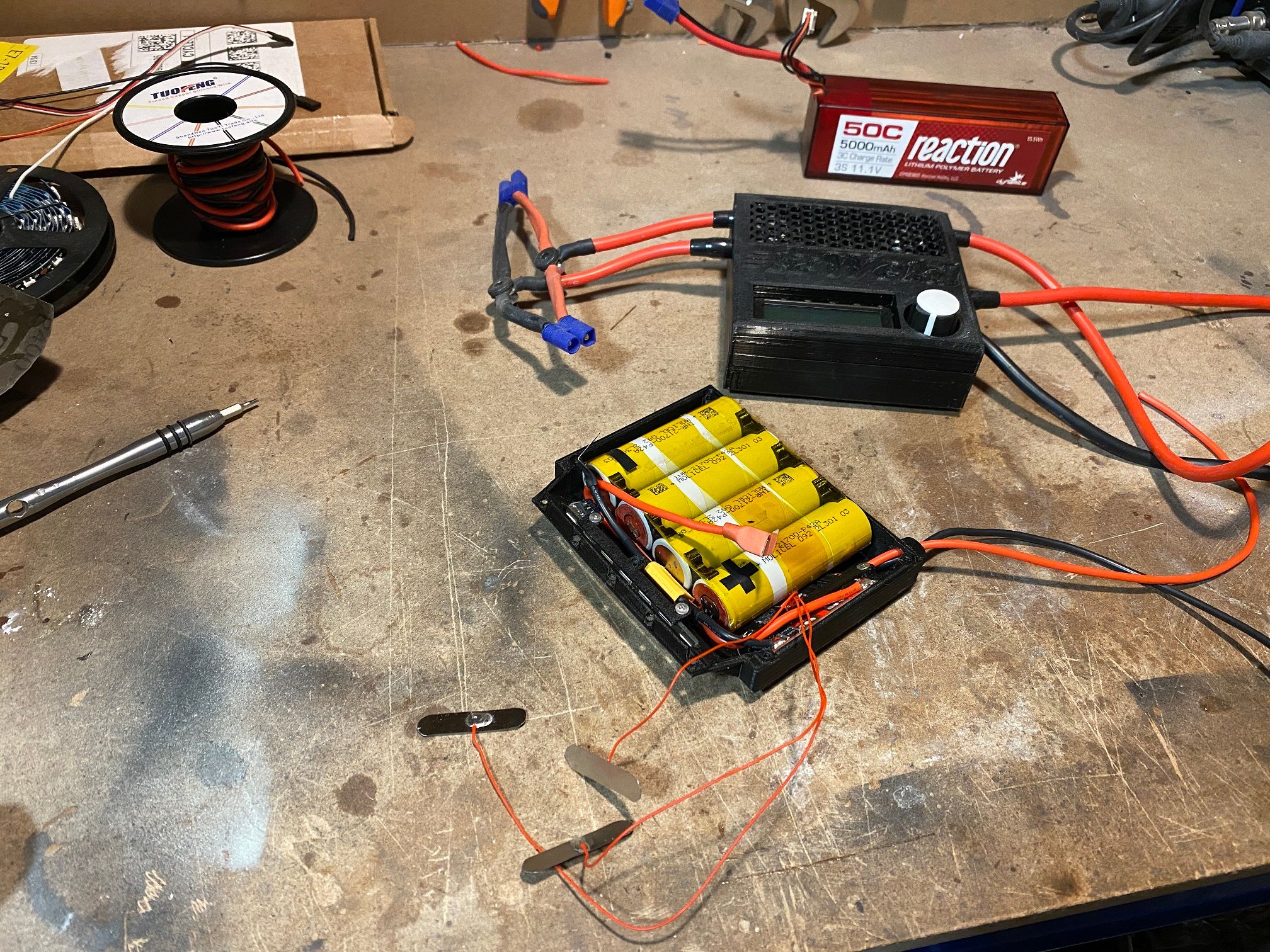

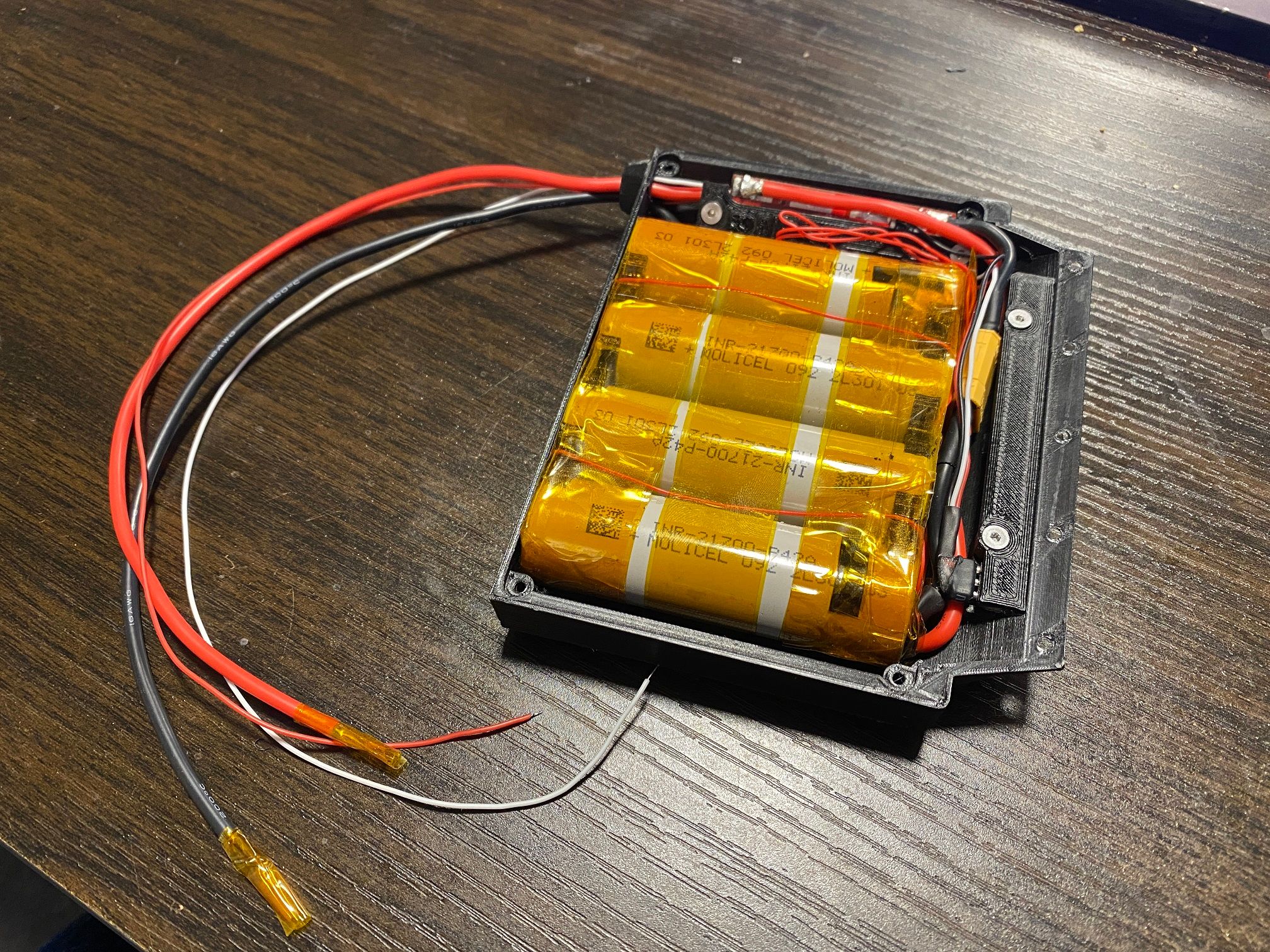

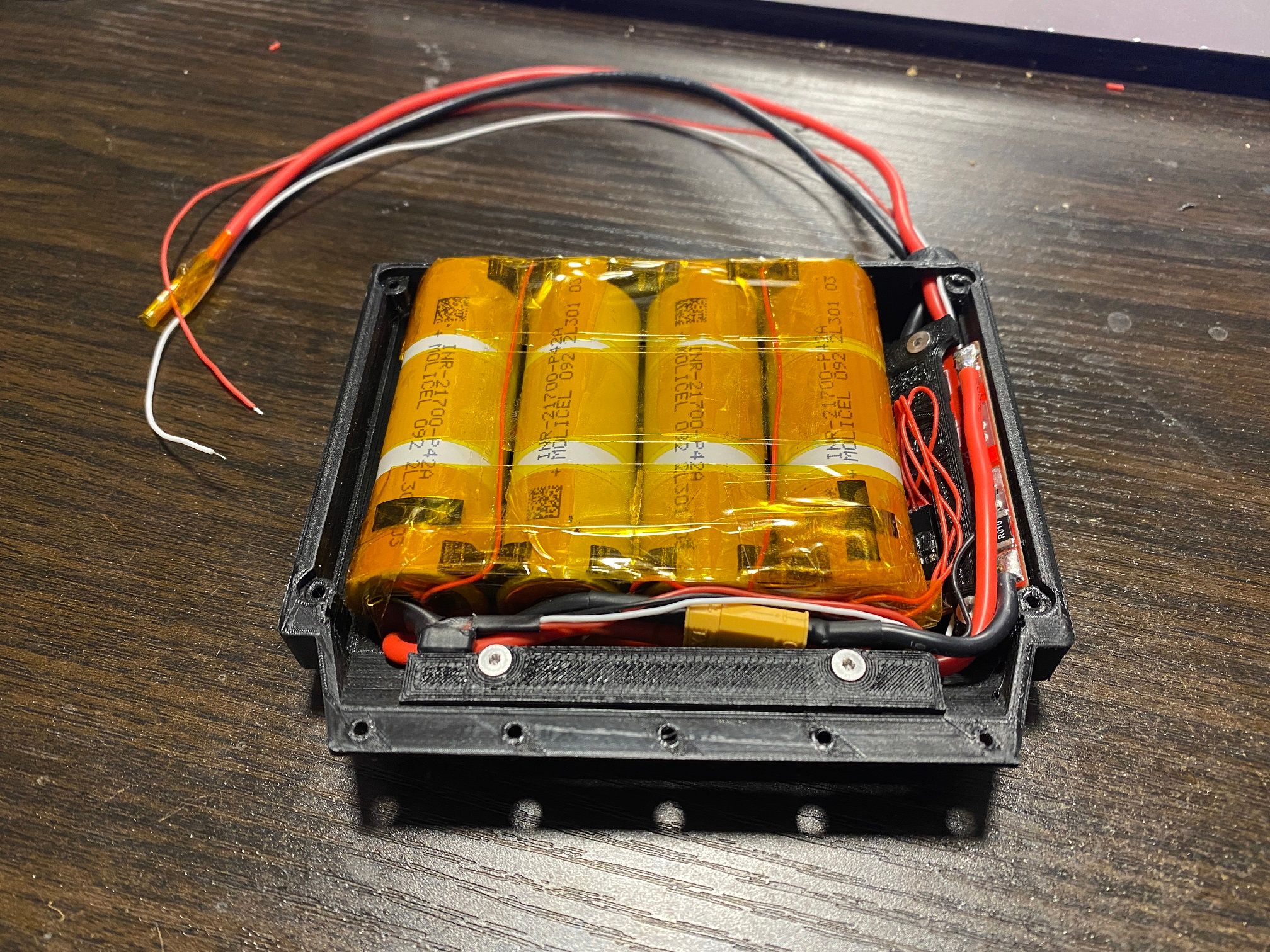

I wanted to get the entire battery section done today. Been putting it off for a while if you couldn't tell. Not sure why but these 4 cells alone are intimidating me more than the 60 Sanyo 21700 cells I welded and frequently have stuck to my back on rides.

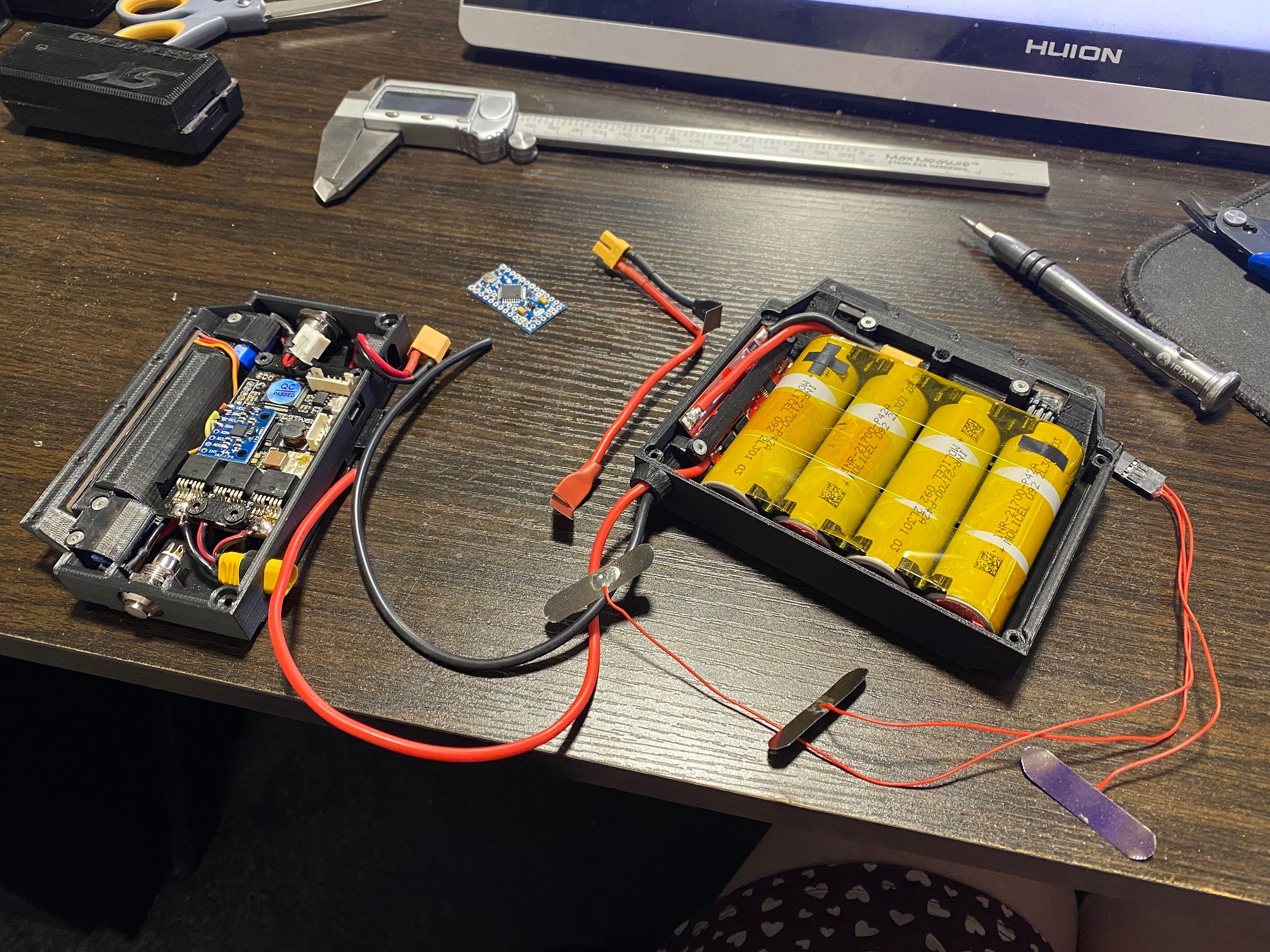

Regardless I decided I'd go about getting it all setup which required a bit of setup and planning before committing. First up was deciding how the wires would route. I've upgraded to 16AWG wire since I think I can get away with that and still have the cable fit around the axle. BMW is held into it's diagonal cradle with a printed brace atop preventing the battery wires pushing it out and shorting on the lid.

Remembered to solder the balance wires on before welding. Not a hug issue but helps prevent heat getting to the cells. Prepared the connector so I can actually remove the pack later if need be since the harness will be attached permanently after.

Got the KWeld out ready to put it together and wrap it in the blue wrap however turns out 1 of my 2 large Lipos was dead. Like dead dead. 1 cells was at 3v and another at 2.4v when the lowest they're meant to go is 3.2v >.> My charger allowed me to still charge it back up to a storage voltage of 3.7v each but I don't want to trust this pack pulling huge currents so left it there and will look at getting a second hand car battery for much safer and better power delivery like I did with the DIY welder a few years ago.

It all however folds neatly into place with enough slack to work with so I'm not skinning knuckles trying to separate the connectors. Hopefully I can get a battery soon and finish up the box to run the board off it's own power and see what current draw I can get away with.

Need to wire the headlight but waiting on some 30AWG wire to come for that since the 24AWG wire seemed a bit much and bulked the cable a bit.

Got V8 of the battery housing printing since the rear P+/- wires were a bit snug under the BMS leaving the housing so made accommodations for that. For now it all sits waiting on my desk for assembly.

-

Decided to charge up my salvaged lipo, paired it with the other and welded the pack together. Thankfully it doesn't appear to have diminished the integrity of the pack and worked fine doing the few welds.

Was on edge the whole time in case the Lipo with the black X on it went up in flames or I made a mistake and set the pack on fire. Thankfully neither happened and I'm in the process of putting the lipos back at a storage voltage.

Here's the pack without the shrink wrap on it. Not pretty but it works. The blue shrink wrap actually made it just too big to fit so opted to remove it. If I can shave like 0.5mm off some walls then I might be able to add it again.

As planned the battery can be removed easily with the way I wired it.

Small red and white wires are for the tail light. GND as previously mentioned is shared on Batt- so I didn't need to have another wire to connect. Here they are working :)

Need to add 2 more wires. SW+ and SW- which will be blue and green. I'll intercept the trace going from pin 3 on the BMS's chip and the output mosfets then wire between them through SW+/- to the power button. Fingers crossed that actually works.

Printing another housing (V9) which gives a bit more space and allows easier routing of the wiring with additional consideration around the tail light.