Vesc Conversion Status (Rose/Mika)

-

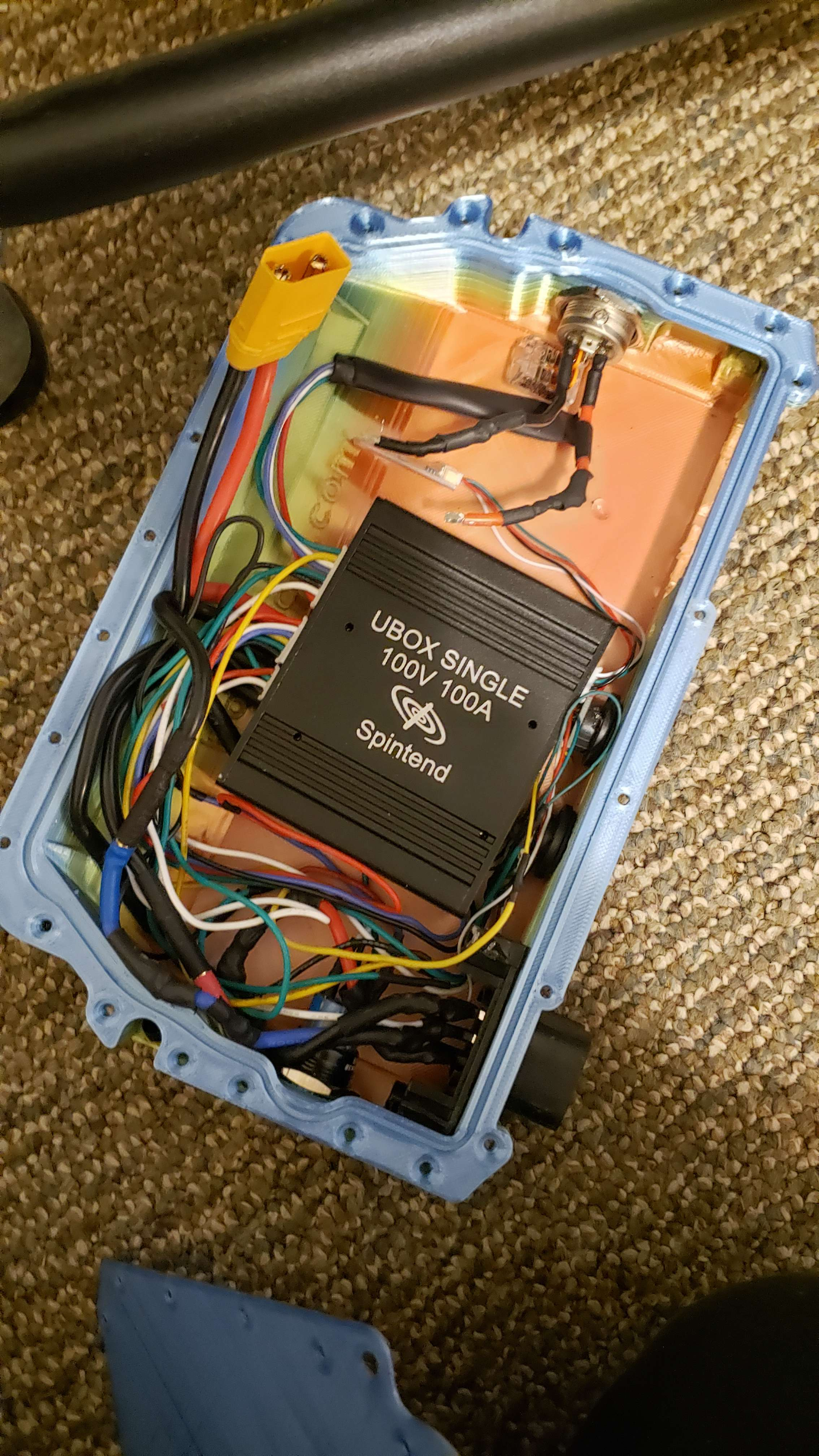

@lia so I took some time and I cracked open the Ubox

Found out that a tiny surface mount capacitor/diode/resister thing poppedI also was running it on 45A field weakening so that might have done it out

-

Ladies, Gentlemen and everyone in between...

We're back

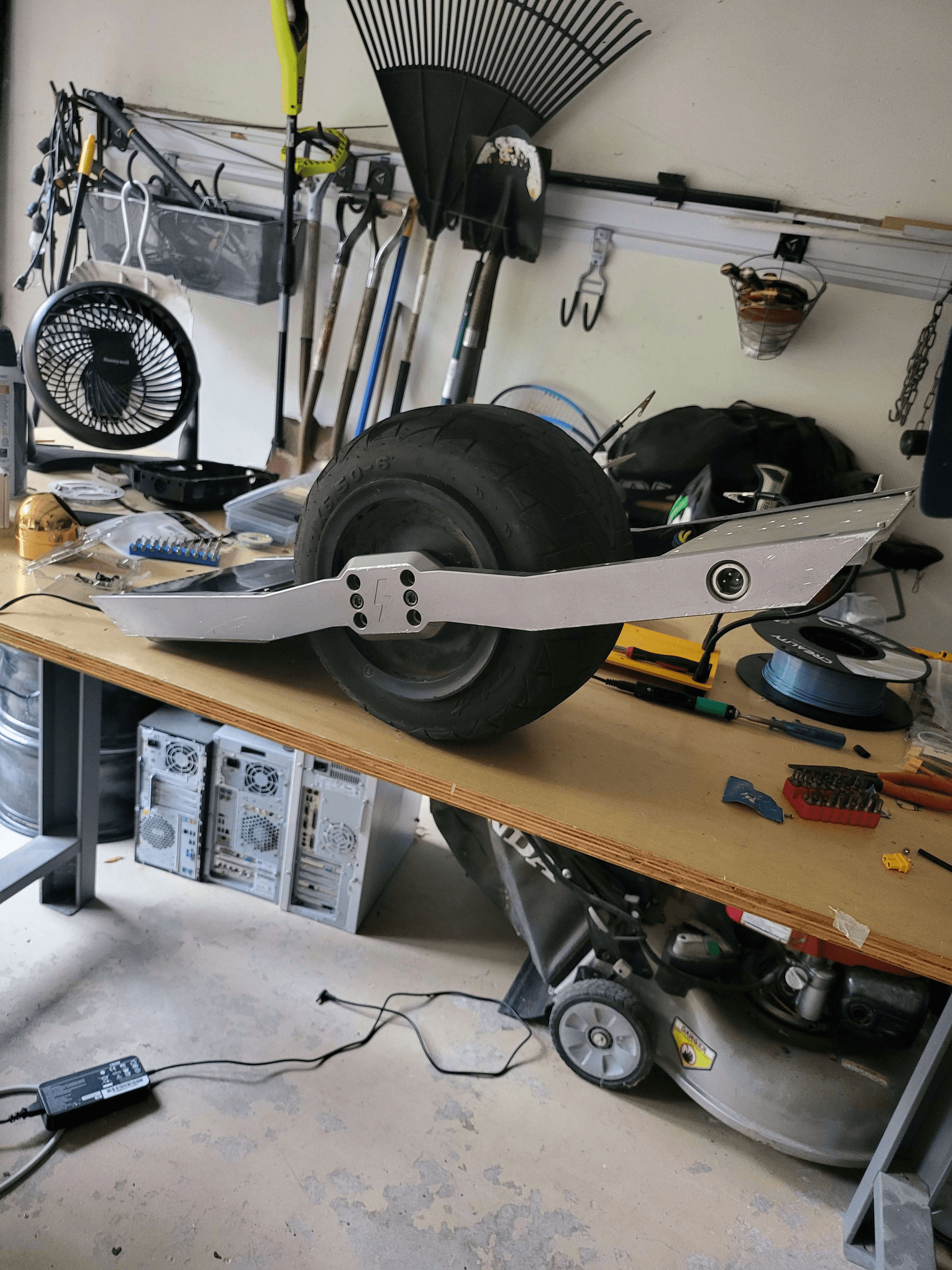

I got my Ubox 100V in. Had to swap it into a 3D printed box. I used 3D printed cylinders as inserts so the screws had something to screw into. The lights don't work and I need to work on modifying a flowglider box to add a headlight pannel.

Motor has some weird crunch, and I'm still working it out

Also, the Ubox 100v is held in using command strips. It works, I'm not gonna complain about it lol

Board kicks like a mule, and apart from water-proofing it and printing out a new controller box using PETG-CF, and a new tire, this thing is basically as close to finished as it will be for a while -

So I wanted higher-desnity LED strips, but I didn't want to spend money.

I did have an LED strip through, so I commited a crime against electronics

It's LED strips cut, then soldered with a bend in it.

I feel like a genius but at the same time I feel scared that I haven't seen something that I should've seen

-

Umm, .. that's a lot of vibration these solder joints must withstand. Thought of some epoxy backing or smth? I have no idea how much room you got there to play around.

-

@sirgu thats the plan

-

I'm back, and I have some news about the board.

The housing that holds the controller is also breaking, as it was printed with PLA that I had lying around.

Another issue is that the motor was acting up, making a “chugging” noise and motion with each rotation. Essentially, at low speeds the motor would drip the nose suddenly before catching the nose and raising it back up. This can be caused by a broken sensor in the motor or a broken cable in the controller.

First we need to print off the new controller box to replace the damaged controller box. As pictured below, the box has a split running across the ports, which could spread and cause the

entire controller box to split and separate while riding, which is not ideal.

I managed to buy some PETG Carbon Fibre filament which should hold up to the abuse this board will inevitably see and make it look less visually offensive. (I mean, rainbows are cool and all but I don’t know if that is the color scheme I want to run with.)

As pictured above, this is the new box that was 3D printed. I am genuinely impressed with the quality of the print. The printer I’m using is a Creality Cr-10 Smart with the hot-end swapped and running direct drive. I would not recommend the Cr-10 Smart, as it has… problems…

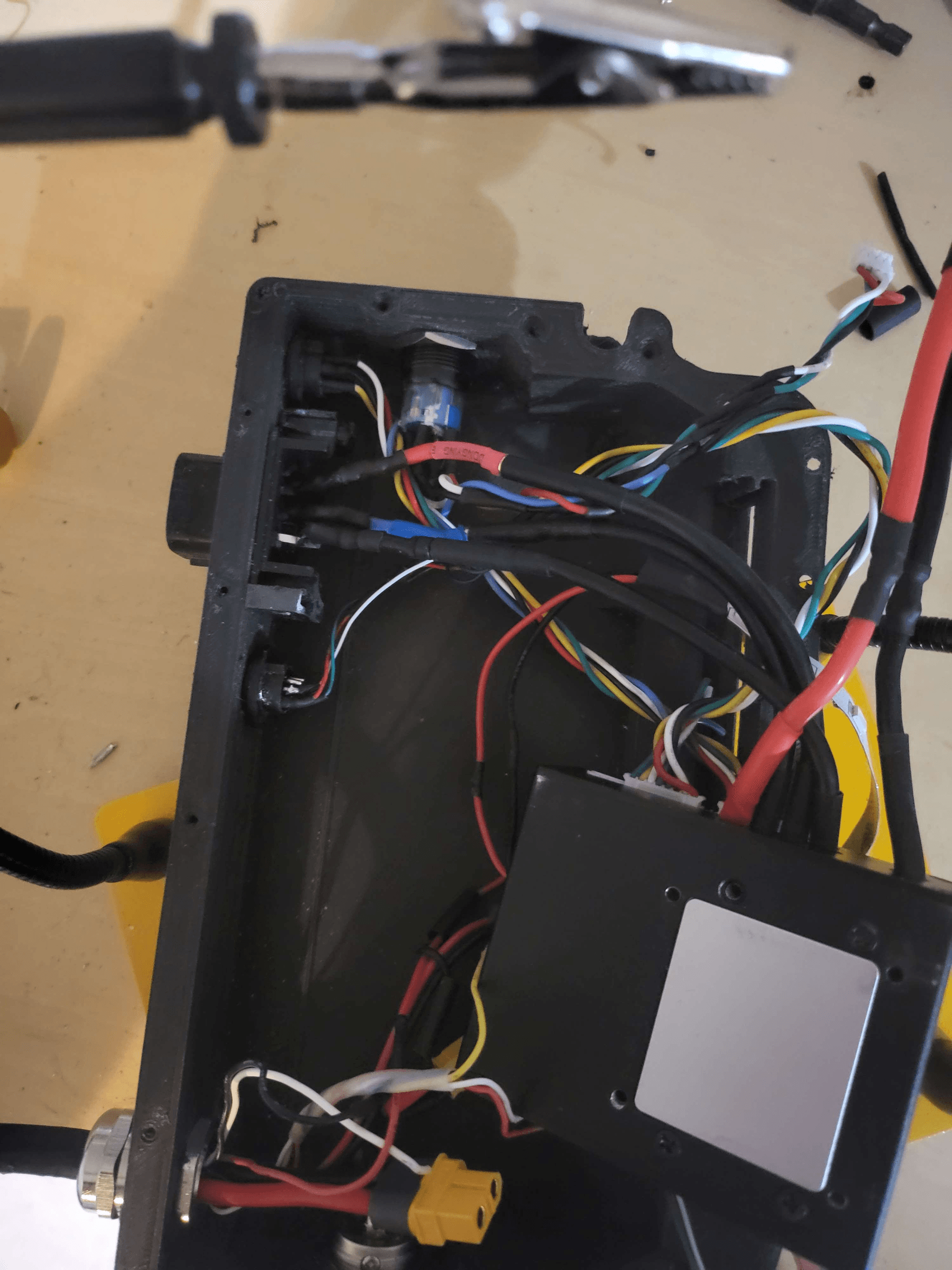

While that prints, we should prepare the cable. First we need to add the proper connector that will feed the battery power to the controller, which is a beefy XT-90. I should invest in some soldering flux, but I will wait until I have a proper work table and not an apartment bedroom and kitchen.

We will use heat shrink to cover the soldered connections to prevent shorting.

On the battery end, we will use some dunpout connectors to create a connector for the back headlights. It took some trial and error, but I finally got the hang of using cheap crimpers!

After that, we can finally get inside the controller box and take a look inside! It’s a rats nest, but I currently don’t have the time to properly measure out and plan a routing path for each wire. I may try and look into getting custom-made PCBs in order to clean up the wiring or at least make it look a little nicer, who knows.

The controller in the center is held in with pressure from the lid and two of those command strips.

I have no regrets for the jank.The old automotive Molex connector was removed, and after +3000 miles of use, it can finally be retired. This was pulled off of the original XR controller board, along with the motor connectors and the footpad connector.

Moving the charge plug from the old controller box into the new carbon fiber one, we can get a better idea of what kind of mess I’ll be dealing with. I should also mention that I had a cable made, along with an adaptor plate cut from a plate of aluminum. It adapts a cable gland to the Molex connector provided by a community member (thanks Pickles!) The cable gland should better seal the cable to keep the water from leaking in while riding through water. The controller box I printed out was modified to fit the acrylic headlight panel from a stock XR box, along with making some extra space inside. (I also tried to remove the flow glider logo since on the previous box it caused some issues with the Ubox and the wiring, but I failed to remove all of them. Don’t worry, I won’t be uploading the CAD model with the text removed. When I upload it, the flowglider logo will be back on there!)

The headlight panel is held in with superglue and a lot of flowable silicone.

At this point of the project, every surface of my room has turned into a workspace. I’m currently using my bed with a bunch of paper towels to work on the controller box.With some rewiring and some continuity testing using my multimeter, I figured out that one of the sensor wires came loose on the motor hall connector. It is not pictured, but I re-wired the connector to make sure this never happened again.

After double checking my wiring and making sure I didn’t break anything, I sealed up the controller box. I measured the circumference of the board, and divided it by π to get the diameter since the tire has seen some significant wear since I last got an accurate tire measurement and the air pressure inside the tire changed, and I forgot what tire pressure I used.

I also added threaded insets so the box could be screwed into using my soldering iron.

Also, a careful look at the picture above and you may notice a 4-pin JST connector. This is planned to be used so I can use external LED attachments without having to use their own batteries. This should let me make a LED fender that I hope to build at some point.

I unfortunately found out that I had to undo some of the lid screws as they intefered with the fitment on the rails of the board. I probably should invest in some counter-sink screws, but that’ll be for later.

The board has been problem free ever since, minus some slight motor crunch while breaking that I can't seem to fix. The board has a ton of kick to it, especially with the 18S battery built by @TheBoardGarage !

-

@loaffette damn, I lost all of my images. I will look at trying to replace these

-

@loaffette Oh no!

Feel free to just upload them here so they don't go walkies. I didn't know discord binned pictures or maybe they just changed the url for them.

-

Fixed a few of the images

Still looking to find the old ones, so we'll see

I also included new wiring diagrams for footpad and hall sensor

I hope it is adequate -

I'm back

I'm fixing my vesc. It's 1 AM, my VESC has been in pieces for about four days.

I've had to rewire and shorten the wires within the battery box, redo the LED strips because they broke, rewire the entire controller-side, remove the footpad and hall connectors from the PCBs, re-solder the controller's XT90 and swap it for an XT60, drill new holes for the controller box because the lid I bought didn't line up with the existing holes, and I've had to do all other thingsslight rant but..

If VESC is ever going to get farther than it is, someone needs to make a few things obvious or make sure everything fits. The last two controller boxes I've printed have had misaligned screw holes for the lid..I'm tired, I'm going to bed

-

-

Back again

Avaspark sent me an STL link for a controller box that should have had everything I needed.

However, it had a bump sticking out that I should have looked at more closelyI can't get the bumper on fully, so I have to re-print the box

-

@loaffette

Can't sand away the bump or is it like not an option?Also... actual bop

-

@lia I don't think I could. That bump goes pretty far into the bumper, and I'm worried if I sand too much of it, I'd be puncturing into the box's cavity

apologies for the venting and ranting, I'm just having one hell of a time with this board right now -

@loaffette responding to this so people can be updated:

Turns out the Field-weakening setting was set to 45A. When I did a burnout on the ground, I think the field-weakening drew too many amps from the ESC and blew it.

So now I keep my field weakening current under or at 35 amps -

@loaffette No worries, feel free to get it off your chest.

Hopefully it all starts to just drop into place soon for you! -

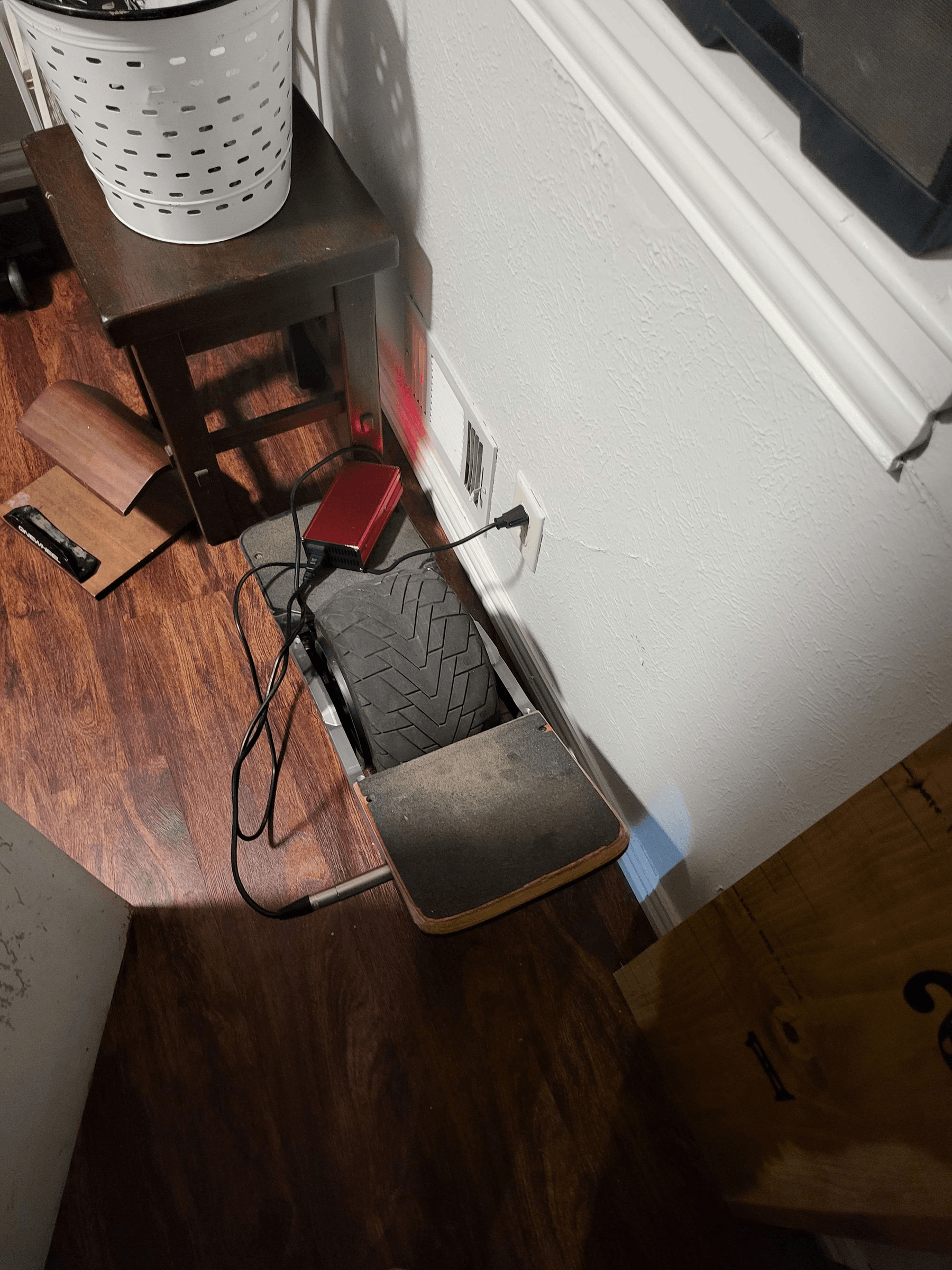

The board is back in one piece

However, there is a problem..

Here it is rebuilt, but in time-out

The board is acting weird. It's very sloggy, and I've made sure all of my settings are set correctly. I am having some weird issues with the yaw orientation, but I'm not sure if that is the problem or not. I'm gettgin 15-35 degree offset, not the usual 90 or -90 degrees

-

@loaffette Regarding yaw do you mean it's just drifting?

I could be wrong but on the VESCs I've done with an external IMU the yaw is ignored as you really only care about pitch and sometimes roll. -

@lia figured it out

It was some pitch orientation problem. I redid the IMU calibration a few times until I got it working -

@loaffette Congrats! ^-^