GTXR conversion- version 2

-

@lemur Agreed, I haven't seen anything to prove the actual hardware has been adjusted now that we've seen inside. Both appear functionally identical to prior models other than that tiny extended lip. Can safely say it's put to rest the rumours including my prior assumptions.

Curiously has anyone benchmarked the stock GT hub vs a modified XR hub on the same GT board to verify any performance shifts? I wouldn't expect a noticeable change but since there is a minor exchange from rubber to aluminium it's possible there's a tiny weight shift.

-

First, I will not have into account the hub pairing, as it was discovered just a day ago or so... So please disregard this aspect for my entire comment.

Obviously people are starting doing the GT stator-> XR rotor conversion, I guess because the connectors are different. Otherwise, with your theory, doesn't make any sense to do the frankenstein, if you could use directly the XR hub (if it is the same, why not trying to use the entire XR hub instead of doing the mix, trying to create a compatible adapter, being the same?)

What I have heard, is that the GT is 3 hp not just because the battery, but the hub is not locked as the XR is. The XR is locked by design in the circuitry to not go further certain currents, rpms, etc... while the GT has increased limits.

And this, assuming that the stator is the same, are we 100% sure that it is? maybe different KV or something?? Maybe something internal that we can't see?

Just talking loud and guessing, not having any trustful information, just what I have read outthere

-

@ed_co I've been riding the GT before and after GTXR conversion , I don't notice any difference in power delivery, the only difference is in the handling due to the Burris tire I'm using.

The carving is the same as my XR with the same tire which is great, just waiting on the TFL Enduro tire now, I had to lower the stock Gt tire down to 10 psi for my weight to ride comfortably.

To use the XR/Plus complete wheel, assuming that the GT wheel is not paired, I would have to cut the GT motor cable, since the connector is proprietary. Since it's still under warranty, and I don't want to do anything that is not reversible. -

@lemur said in GTXR conversion- version 2:

@ed_co I've been riding the GT before and after GTXR conversion , I don't notice any difference In power delivery, the only difference is in the handling due to the Burris tire I'm using.

Obviously, you are using the same stator... I was talking about a possible change they could made in the stator, which could make the GT hub more poweful... not the rotor, which is just a case with magnets.

The carving is the same as my XR with the same tire which is great, just waiting on the TFL Enduro tire now, I had to lower the stock Gt tire down to 10 psi for my weight to ride comfortably.

Enduro rocks man, I am sure it will be kick ass ;)

To use the XR/Plus complete wheel, assuming that the GT wheel is not paired, I would have to cut the GT motor cable, since the connector is proprietary. Since it's still under warranty, and I don't want to do anything that is not reversible.

I was not thinking about cutting, but make an adapter. I am sure there would be a way to do it (even with a 3d printer if needed, I have seen amazing things done by Lia, making even custom connectors with a 3d printer). This would show us if the hub is actually the same power or not as the XR one.

-

Hmmm... I could probably use a GT hub with an XR stator on my Plus, right? That is if I did not mind the hard ride and was willing to deal with the tire when it wore out. Someone will likely want to rid themselves of one. I will keep an eye out, and if you know of anyone who wants to part with a GT hub let me know, thanks.

-

@s-leon I think until the warranty period ends, you won't see any GT rotors on the market.

-

@s-leon said in GTXR conversion- version 2:

I could probably use a GT hub with an XR stator on my Plus, right?

The GT stator doesn't fit in the XR hub without modification of one of the two. Would this also be the case for the other way around? Is it possible the wheel could float left and right (the 1.6mm, or whatever) as you rode?

-

@biell said in GTXR conversion- version 2:

Is it possible the wheel could float left and right (the 1.6mm, or whatever) as you rode?

I guess with a shim on the axle to accommodate the gap would be fine.

Wonder if the OD of the axle matches standard sized tubing. Could match the OD with some aluminium tube that has a matching ID (maybe a hair bigger for tollerance) instead of machining out a chunk of aluminium stock.@Lemur Was there any other chips or additional pins on the motor connector for the GT? I've heard rumours a hub swap prevents the GT booting as if they managed to serialise it. Curious if it's something on the hall sensor PCB or they moulded something into the connector as we saw with the charge connector.

-

@biell You would have to shim the XR stator to fit ibn the GT rotor.

-

@lia I just tried disconnecting the motor cable and a red flashing error code comes up when it's powered up, and I forgot to count the flashes, duh.

The circuit board on the Xr and GT looked similar but when I had it apart, but I wasn't looking for any differences because we didn't know about the married stator at the time.

The motor connector has the usual 3 large phase and 6 small pins for hall(3) 5v, ground and temp. Some people are speculating something may be in the large motor connector , which is molded something like the charger plug which has a chip in there. -

3rd parties already moving to masses with these.

-The shim/adapter variant ::

https://plasticspider.com/gtxr-adapter-plate/

-The rotor plate cover variant (about to be released) ::

https://www.facebook.com/photo/?fbid=4705201749581233&set=gm.275369091459873

[yes, a FB link but click on it, no log in required] -

-

@biell The wheel with either conversion is only offset to one side by 3.52mm , that amount is not noticeable when riding.

Your feet move around more than that . -

@lemur Thanks, good to know in case I want to go this route.

-

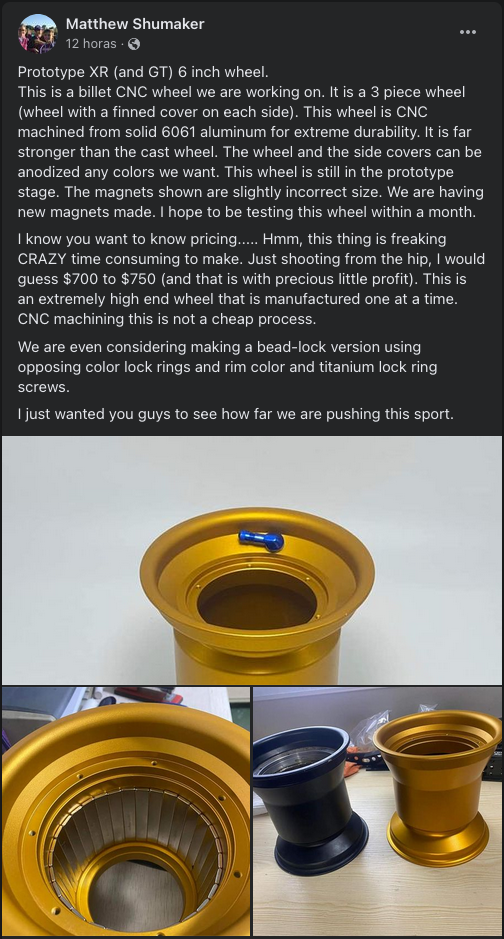

I think this should be in another category: OW porn (you should create it Lia)

Enjoy ;)

-

@ed_co Wait... wait wait wait... this is custom... someone made this??? OMFG it looks so good! I didn't think anyone would be committed enough to put the time into make this.

Holy... who did this? I want to know what they went through to put this together... was it cast and then spun to shape or straight made from a chunky bit of stock?

And yes... maybe a nsfw filter might be in order too ;)

-

-

@notsure said in GTXR conversion- version 2:

@ed_co said in GTXR conversion- version 2:

Enjoy ;)

wut! i want one.

Seriously doubt it, at $700-750, it is a little bit expensive... That's fucking mental

All yours guys, I think that the DIY greedy is starting getting just insane, even worse than FM.

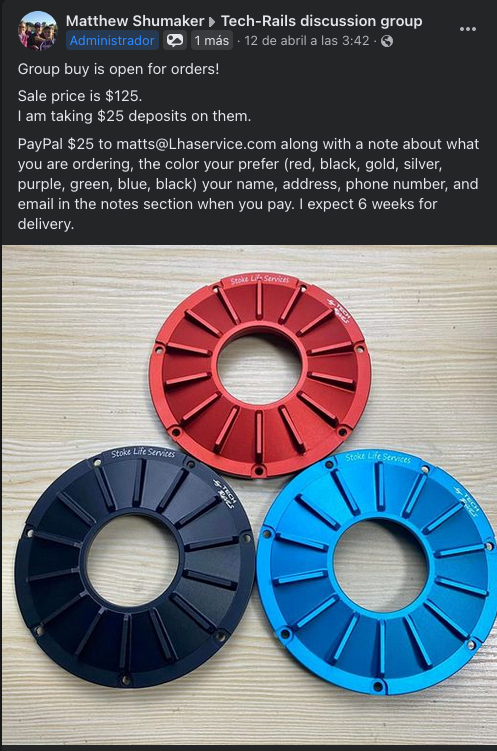

Look how much is just the small cover. CNC is not cheap for sure, but in 100s units production this doesn't cost $20. Is this not greedy? For me is just abuse, the problem is the community is paying for this things... and the prices are increasing for this reason.

Now for a VESC + BMS, we have to pay more than euro600, to start with, having a pint for around 1000. This is just starting to get insane...

-

@ed_co Agreed! Every fart the aftermarkets create costs gold nowadays. Greed is key, getting ridiculous. I sometimes feel like selling my shit when XR's die and get a Ninebot z10. It's not as fun but i notice my pride is starting to get in the way.

I do understand making the rotor from a chunk af alu is expensive so the pricing is somewhat understandable. People will buy it, it's design+need. But fuck no i will NEVER buy this.

-

@ed_co said in GTXR conversion- version 2:

$700-750, it is a little bit expensive

It's bound to be. There is a negligible economy of scale here with presumably a single guy with their multi-axis CNC mill doing these 1 at a time. Even milled from hollow stock I can't see this being cheap in material costs for a handful to be made. Solid stock locally for me at around 178mm diameter by 250mm deep is £384 or $500 (smaller sizes from this seller aren't large enough for a hub, this is a bit too large). Ideally casting a rough shape would be cheaper materially but that adds a whole set of challenges and tooling that may work out more expensive for a small run :/

I don't think this is greed, expensive for sure and not worth it but I can't attribute greed here. They expressed there is minimal profit involved and looking at the work put in I believe them. Parts, milling, balancing, anodising, sorting magnets by strength and weight then presumably testing them adds up quick.

Add to that it's domestically made where an expected living wage is to be paid. FM have the advantage of foreign manufacture of parts for cheaper labour plus a lower cost per unit due to the volume made.