"Pocket rocks"? Need for advice by thane experts;)

-

That is a shame, because Electric Stoke is having a great offer now, $175 for one of each. I wish they had this back when I ordered mine, I would have easily taken that offer. https://electricstoke.com/collections/all

One Stop Board Shop will ship internationally, and they do have some models available now: https://onestopboardshop.com/onewheel/osbs-x-electric-stoke-collab-pocket-rock/

I have the Bump and the Gem, and they are fun. I can't get very high, I wish I had gotten the Power Button or the Volcano. Zack from Florida Float Brothers gets way more air than I do, so I just need to figure it out, I guess. Here is his review

. In it he states that it is some type of polyurethane, but doesn't know what kind. So, you are on the right track, maybe look for a kind that advertises some grip to it after it dries. -

@biell Cheers, checked OSBS, shipping is $58....ouch.

Gotta experiment some more then🤣.Just for my info, how hard/soft is the material? Can you press your fingernail in it easily? Dunno if you're familiar with longboard/skate wheels n bushings for a duro indication?

-

@maciak If I push my whole thumb in, it feels like I get nowhere. If I push the tip if my thumb in, I can feel a minor buckle, and I can push my fingernail in no problem.

It's been a while since I bought a skateboard wheel, so I can't even comment on a hardness number. I will say that it feels more rubbery than any wheel I ever had, and I certainly wouldn't have wanted to slide on wheels made of this material. For me, it wold have ended up more of a sputter than a slide.

I hope this helps.

-

The recipe.

@maciak said :

... I tried to pour a softer compound as bottom layer but it won't bond. ...

1.) Mildly textured rubber sheet as bottom layer. The real sturdy SBR type rubber. NOT nylon; nitrile; neoprene .. steep-pattern textured "foam-rubber". Try as thin as you can find.

(Such stuff is usually sold in agricultural & farming equipment stores.)@maciak said :

... Also glues seem to fail to bond to the softer compound. ...

2.) Single component polyurethane ('hobbyists'-)glue (with toxic solvents) as an adhesive for your slick-hard A75 polyurethane form against SBR rubber.

Look towards Stormsure. Or AquaSure; AquaSeal.

If you are new to this stuff - you'll bestoked*cough-cough .. amazed of how many different materials with various characteristics these can bond!

(!) AVOID using Casco RubberFix (which is their recent equivalent for former superb product called LiquiSole) - they decised to go eco-firendly by removing toxic additives. Assuming the enthusiasts and DIY-ers are not responsible enough with glue leftovers and wastages. -

@biell This info is pretty useful, thanks! I think the main thane i use is harder than you describe. It would actually make a pretty good grip to slide longboard hardness.

Im on a different track now with a "special" formula. If i get the main hardness close enough it should grip like a maniac🤘🏼. De-molding will be 12hrs from now.

-

@sirgu Cheers, will check out the products you mentioned. Just trying something different first, will update tomorrow.

-

@maciak cool project but that color scheme is hideous! looks like a moldy egg sandwich.

-

@notsure 🤣🤣 It is hidious indeed! Just had blue pigment to work with..that brownish stuff is the original color. I think the one that's curing atm will end up like a chewed up smurf.

-

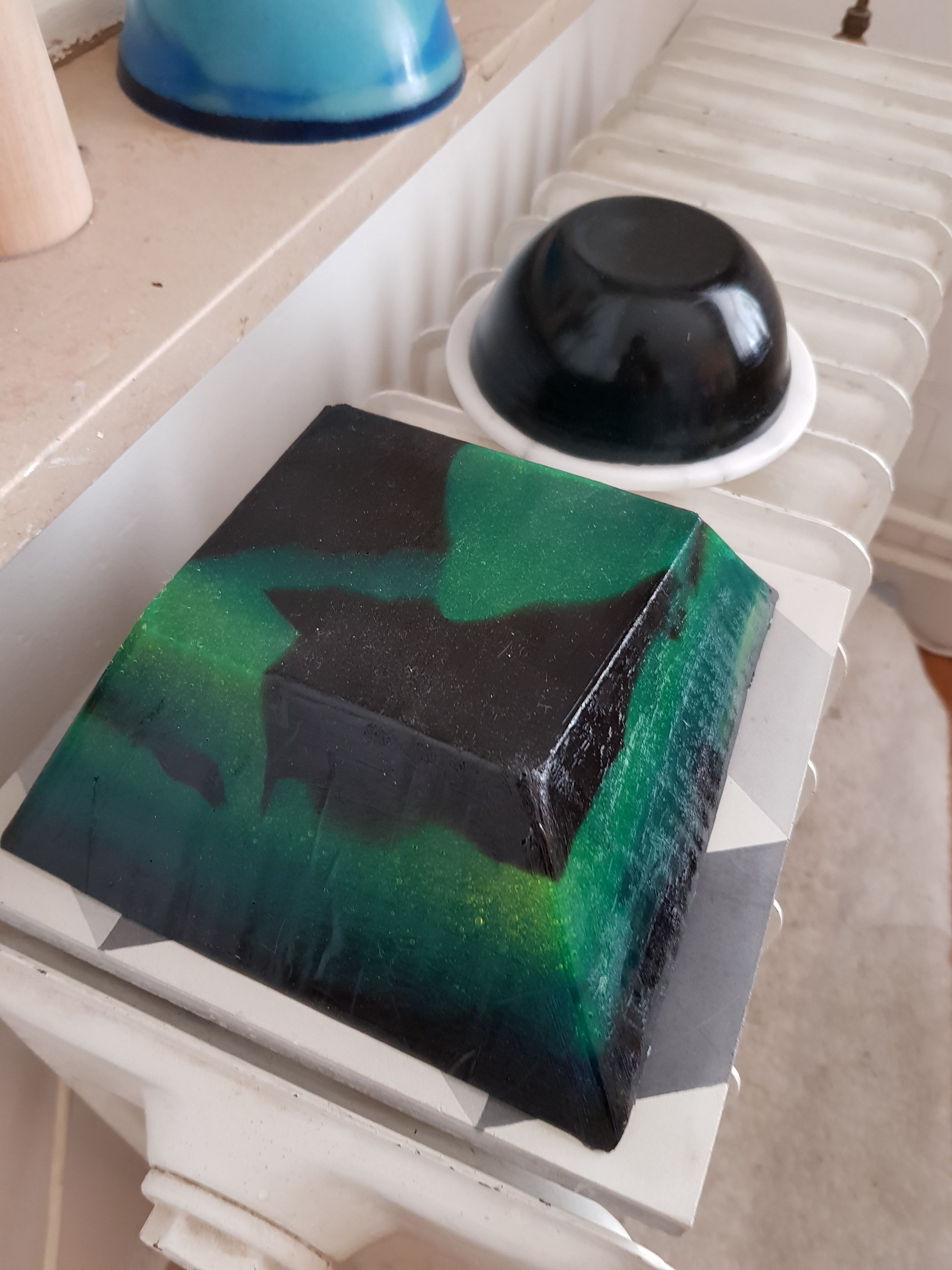

My take on the "powerbotton"!

This time the mold ("borrowed " from the kitchen) survived saving me a hard time with my beloved;)

I used the A40 soft compound i had left. Mixed it with chopped up glassfiber (powder) as filler that i use for epoxywork. This clearly increased the hardness to desired level.

The bottom couple mm is without the fiber and grippier than grippy, it's not going anywhere. Still needs to cure a bit since the filler and softer compound increses curetime. -

@maciak This looks great, and definitely reminds me of the ones I purchased from ElectricStoke. Nicely done, and I hope it works out for you. I love the shape!

-

@biell Thanks. Still wish i could get an original in my hands to compare. But i think this is pretty much what it is. All together i ve spent €50 for the other 2 rocks+this one on material which is still less than OBS shipping only;)

Just another question, sorry to bother..if you squeeze the rock really hard like in the pic, does it budge like this? (basically try to bend it).

-

@maciak I don't get that much bend, maybe 20% of that. Mine barely bend at all. I have a Bump and a Gem. The former looks to be smaller than yours and the latter looks to be bigger.

That being said, your minor bend might actually be superior. What is important is how high you can get off the bonk. If it compresses a little, but has the strength to bounce back while you are still in contact, you might get a bigger bonk from the reaction.

-

@biell It's hard to determine what hardness to look for without having an original, really need my hands on one.

Honestly i think softer is not beneficial as it always will absorb more than it can return. It bonks for sure but have not been able to use it somewhere i can accellerate better. It rains all the time too, there is no thane that grips reliable on a wet surface.

The harder compound i used does not bend or budge at all, so i must look somewhere in between. But the grippiness of the softer one is just perfect, as the harder compound gets sketchy..

In the mean time i made a mould for the "Gem" out of cardboard and play a bit more with properties of this material to understand it better..If i find the ideal hardness, making the largest rock (volcano) would cost €25 max to produce..

-

@maciak That makes sense about the hardness. I think you are really close, so maybe just a bit more. For my Gem, I found I like hitting the corners better than the flat sides, so try that too when you are testing it out. One thing to note about the ES Gem, the shorter sides have a steeper angle, so I found that riding up the short corner gives me the most pop.

€25 sounds pretty good, but it also sounds like you are having fun with this, so it is all money well spent.

-

W.I.P. 2 different formula's

-

Curing..So far hopeful this will work. Off course this thane is 30% more expensive than the A40...couse it's Onewheel related😖

Edit: So the thane for the squared one is 85 Shore A. The bottom 5mm is 55 Shore A and yes, this brand has similar cure character and mix ratio. They actually bond really really well.

Only thing i dont get is that the stuff i used starting this topic was A75...which is actually harder and less grippy than A85. They're different brands still i dont understand this difference.The dark round one is pure 55 Shore A. No fillers used and is at this time same hardness as the blue round one (A40 with filler). Might still harden a bit more, still not fully cured.

All together i might have found the correct duro/grip combo. These ones are bit less grippy than A40 but definitely grippy still.

The initially used A75 will no longer be used for these, it's unsuitable compared to the more recent ones.

-

@maciak Does the heat help the curing process, or is that just a convenient place to store them while they cure?

-

@biell Heat shortens the de-molding process. Im thinking it could help after de-mold as well cause they're not fully cured yet. I could be totally wrong, know jackshit of this material really🤣

The softer one bonks fine in the limited room i have in the yard. Not impressive but neither am i...just bonk stuff to get over it on trails usually.

-

@biell Just 1 thing i noticed (ok there's this green stuff and some dirt between the stones):

After a while with some movement the bottom of the rock gets dirty and looses grip. So a clean-wipe is needed to regain full grip again..

-

@maciak I have to say I love these colour choices~

Great work on these and thanks for sharing the process :)