GTXR conversion- version 2

-

@ed_co said in GTXR conversion- version 2:

buying a hub case for 75% of the price of a pint

Yeah, it's nuts. There are certainly ways to cut those costs down and hopefully they do since it won't be long till decent motors are worth their weight in gold.

Personally I'd be casting the rough shape then milling the excess. Less material waste per unit and the milled shavings can be remelted back down to feed the next batch. Some losses in impurities but with the right skill you're not looking at that massive initial investment in material costs. That's assuming they can make a re-usable mould and aren't hand packing a sand cast every time 0.o

-

But the WORST THING that I just found out, and this is making me freak out. Is a XR/GT hub size and just the external cover will define in what could be incepted, meaning, it has the problem of not being centered!! $750 and is not even centered!! Seriously, I hope I am wrong, but...

-

@ed_co The hub is open both ends on this custom one so I think the idea is you get the hub casing then a set of the covers depending on if it goes on a GT or XR since that's where the spacing occurs.

-

@lia oh, so both ends... Gotcha. So both ends will adjust instead of just one... Just ignore what I wrote before. Well for almost the price of a pint, I couldn't expect anything less... Cheers Lia!!

-

@ed_co I'm just guessing, it's the most sensible way to do it considering the sheer cost of the thing.

I don't think I could ever use one of these even at half the price. It's practically the cost of an entire motor but the one part that can get irreparably damaged by riding rough.

Hopefully they include some stickers to sweeten the deal though ;)

-

@ed_co I think it will be centered because there are two end covers, one on each side so they can change the offset any way they want . But this is really overkill, this started as a $10 shim and morphed into a high dollar hub, which will prove a little useless when the 6.5" TFL Endouro tire comes out.

I can see if Tech Rails had a controller other than a vesc that can outperform the GT and build a high end board for the people who can afford it , much like a high end car. -

@lemur with all your machining capabilities, are you able to do one hub for yourself? Or you don't have the necessary required equipment to do it? Would love to see it from someone that I respect which is not trying to abuse from people and through bait just for fishing someone stupid enough to buy it

-

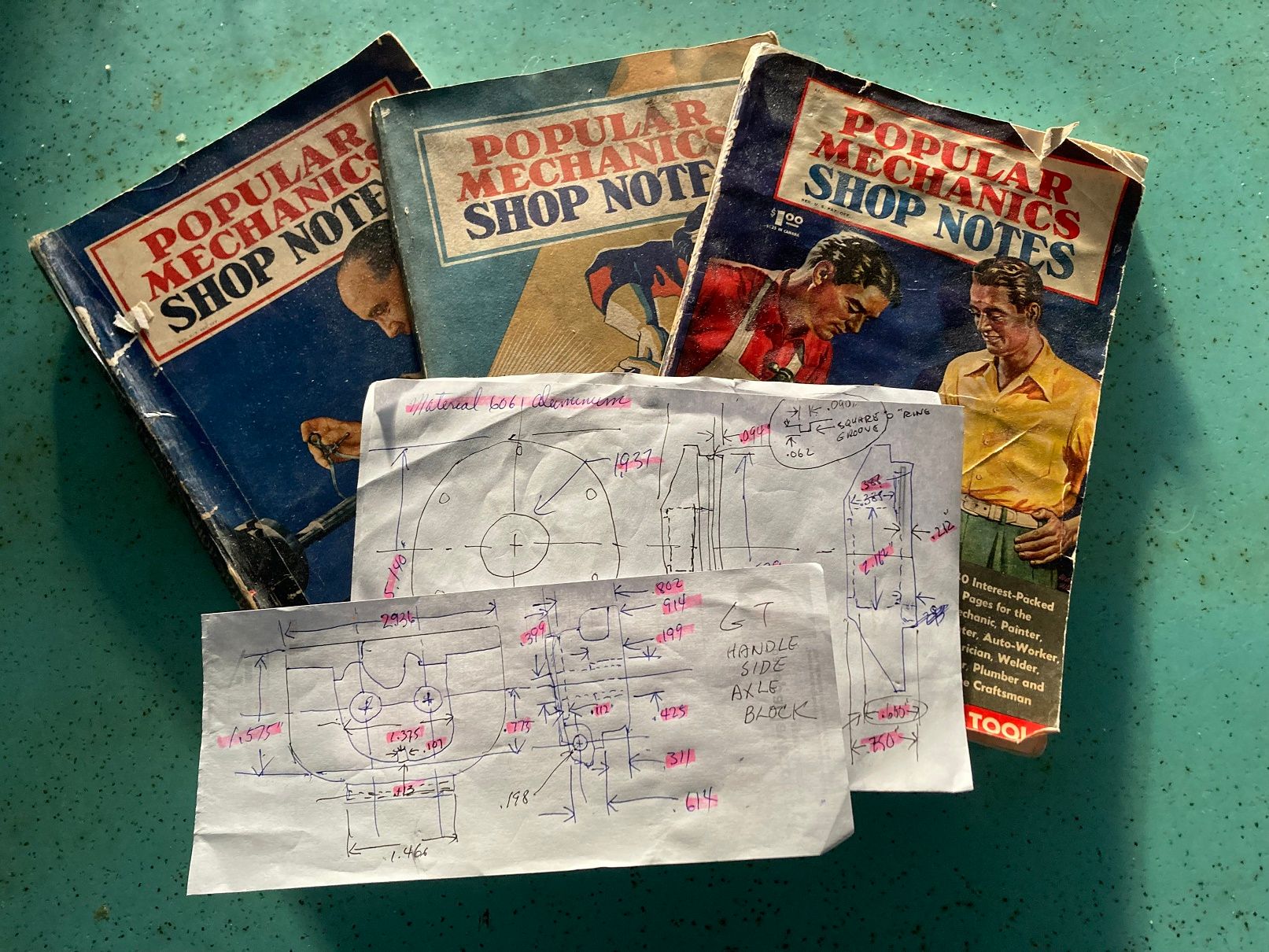

@ed_co It's not the machining, it's the 6061 billet cost , magnets and the time involved to machine a hub , any mistake and probably $300 billet ends up as a barrelful of shavings.

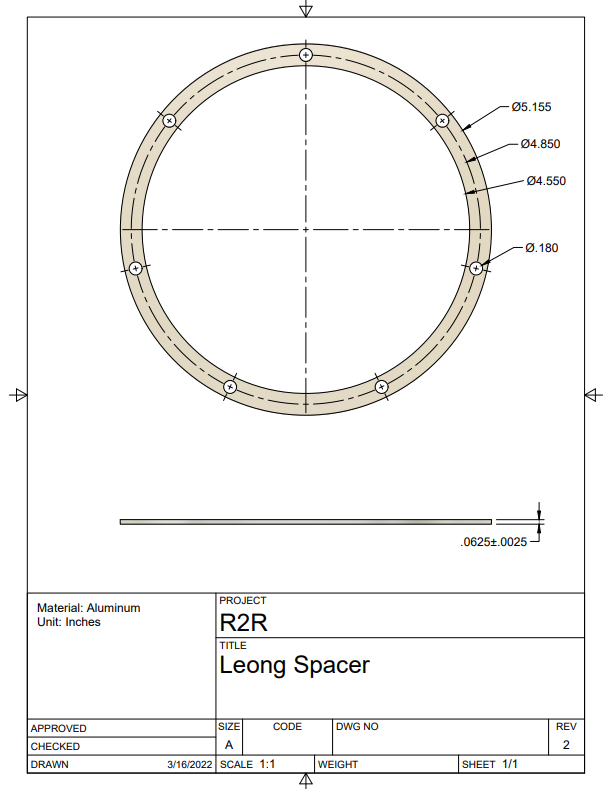

A cast blank ends up no better than the stock hub anyways. I'm totally happy with the shim and offset axle block, although I have a billet end cover ready to go with an added oil seal to boot.

I was going to suggest to Tech Rails that they add seals, but no point if they can' think ahead. -

@lemur Do you have the cover and the mounts designed in a file?

-

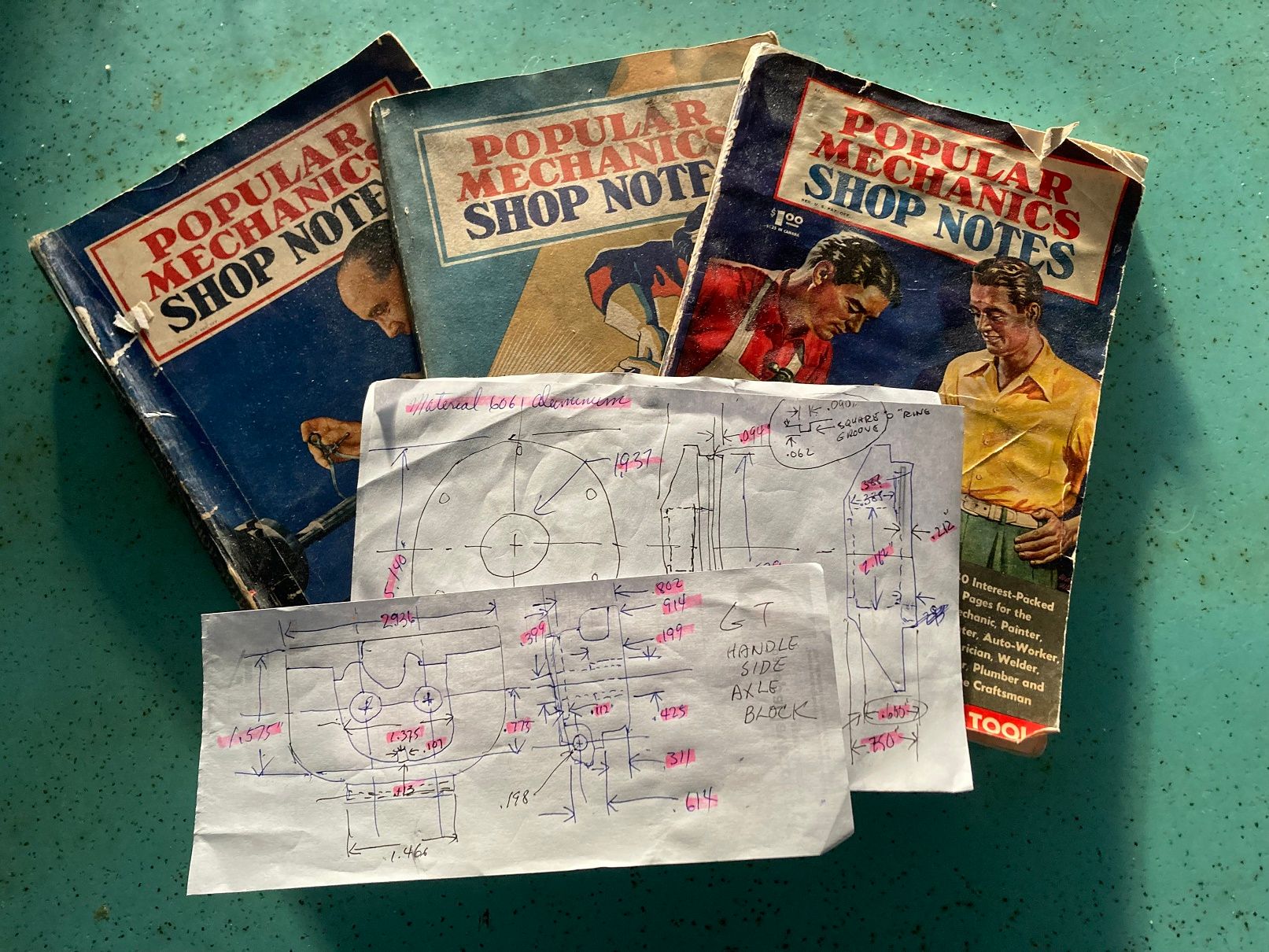

@ed_co Sorry, these parts were a one off and plans and dimensions were hand drawn on scape pieces of paper. I'm the last of old school , I always liked the way things were done before cnc and cad, but I also embrace high tech.

-

@lemur said in GTXR conversion- version 2:

@ed_co Sorry, these parts were a one off and plans and dimensions were hand drawn on scape pieces of paper. I'm the last of old school , I always liked the way things were done before cnc and cad, but I also embrace high tech.

So nice sir, appreciate your pictures either way. Very old school and classy!

Have you solved the handle thing? -

@ed_co I really don't miss the maghandle and it rattles anyways.

-

@sirgu sorry for what are probably dumb questions, but is that Adapter Plate from Plastic Spider plug-and-play, and would it be pretty obvious what I needed to do when I open the 2 hubs up for mating? Or does it still require any machining of parts (which I do not have easy access to)?

If it's as simple as slapping that Adapter Plate in there, I'm ordering, that's a relatively cheap and easy solution, unless there's something I am missing!

Also, in my understanding there's no difference whatsoever between an XR and a Plus hub, correct? (It would be a Plus I would be cannibalizing for this).

Thanks!

-

@Glyph it's always ok to ask away!

And sorry on my side -- I cannot confirm the simplicity neither thoroughly endorse either methods firmly to anyone by the lack of personal experiences.

The least I can tell (by looks and comments) regarding to shim/adapter variant:- It sure voids your warranty (like any other action does).

- And still you gotta keep in mind:

@Lemur said :

... The wheel with either conversion is only offset to one side by 3.52mm , that amount is not noticeable when riding.

Your feet move around more than that .That been said ...

if you're curious about in depth insight about possible challenges within that mod process, @Lemur 's input is what you need here.

Or Facebook group "Onewheel GT owners" presumably shares out more information about ppl experiences with particular "pLaStic sPiDeR" shim variant.

(I'm not in there .. can't copy-paste anything.)

It is ass itching to sort out and have a hold of useful information throughout the Facebook space. Especially retroactively. But it's somewhat doable. -

@sirgu - Thanks, we'll see if Lemur sees your tagging. Also curious what is meant by the handle issue - do these solutions require removal of maghandle due to space?

Also, looks like the wheel covers are available for preorder at Bob's (as "Disc Golf Markers", lol).

-

@sirgu I think the plastic shim is either a carbon fiber or a printed shim. I saw something about them, but I can't find them online anymore.

However, the only suitable material for a shim is aluminum as the printed ones will compress too much, the shim also determines the stator end play.

A simple $5.00 shim will work great, I've been using the shim for a while and have no problems, but I also machined a custom end plate which I will install later.

The shim or endplate method results in the wheel being offset about 0.138" or 3.5 mm to the left which does not affect the rideability at all. Another way to use the Xr/Plus rotor is by milling the bearing pocket in the Xr/Plus by .064" and that results in less of an wheel offset.

I machined a custom axle block and shim to move the wheel back to center because I can. The custom axle block has no provision for the mag handle and I don't miss the handle as there is still the hand grip in the front.

You can also mill down the stock mag handle axle block, but not at the moment as there is still warranty left and I didn't want to alter any stock parts yet.

-

Yea, the pLaStic sPiDeR's equivalent product is/was made from aluminum. [Out of stock by now!] Just the name is misleading. :}

-

@lemur I love how professionally done your work is. Even going as far as to make the actual design plans properly.

-

@lia I can't take credit for the drawing, a friend professionally drafted the design from my scrawlings. Haha.

On another note, I see you're on a couple of discord channels.

-

@lemur said in GTXR conversion- version 2:

I see you're on a couple of discord channels.

I think I'm only in the 1 currently (FloatTown) and it's kinda deserted. Was in another but it was far too chaotic so left not too long after joining. Kinda trying to get off the platform at some point tbh.