GTXR conversion- version 2

-

-

@notsure said in GTXR conversion- version 2:

@ed_co said in GTXR conversion- version 2:

Enjoy ;)

wut! i want one.

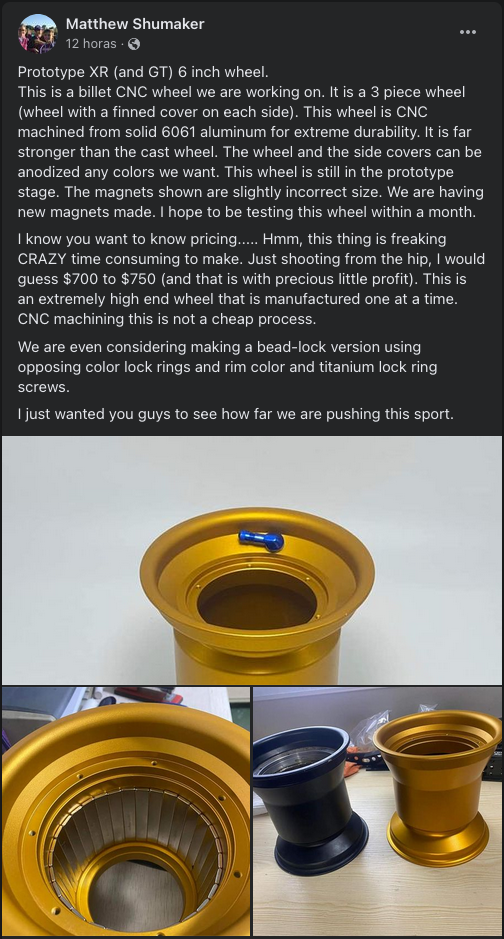

Seriously doubt it, at $700-750, it is a little bit expensive... That's fucking mental

All yours guys, I think that the DIY greedy is starting getting just insane, even worse than FM.

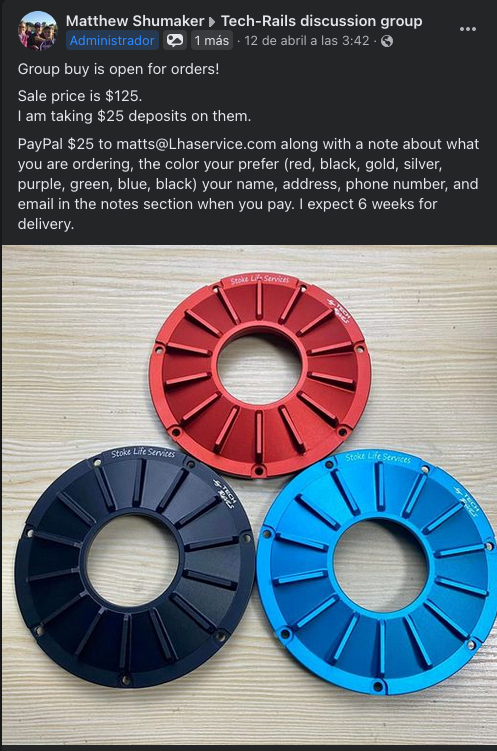

Look how much is just the small cover. CNC is not cheap for sure, but in 100s units production this doesn't cost $20. Is this not greedy? For me is just abuse, the problem is the community is paying for this things... and the prices are increasing for this reason.

Now for a VESC + BMS, we have to pay more than euro600, to start with, having a pint for around 1000. This is just starting to get insane...

-

@ed_co Agreed! Every fart the aftermarkets create costs gold nowadays. Greed is key, getting ridiculous. I sometimes feel like selling my shit when XR's die and get a Ninebot z10. It's not as fun but i notice my pride is starting to get in the way.

I do understand making the rotor from a chunk af alu is expensive so the pricing is somewhat understandable. People will buy it, it's design+need. But fuck no i will NEVER buy this.

-

@ed_co said in GTXR conversion- version 2:

$700-750, it is a little bit expensive

It's bound to be. There is a negligible economy of scale here with presumably a single guy with their multi-axis CNC mill doing these 1 at a time. Even milled from hollow stock I can't see this being cheap in material costs for a handful to be made. Solid stock locally for me at around 178mm diameter by 250mm deep is £384 or $500 (smaller sizes from this seller aren't large enough for a hub, this is a bit too large). Ideally casting a rough shape would be cheaper materially but that adds a whole set of challenges and tooling that may work out more expensive for a small run :/

I don't think this is greed, expensive for sure and not worth it but I can't attribute greed here. They expressed there is minimal profit involved and looking at the work put in I believe them. Parts, milling, balancing, anodising, sorting magnets by strength and weight then presumably testing them adds up quick.

Add to that it's domestically made where an expected living wage is to be paid. FM have the advantage of foreign manufacture of parts for cheaper labour plus a lower cost per unit due to the volume made.

-

@lia Things like the hub, I am not saying that have too many profits. But the price is just ridiculous. I was not saying about this paricular part.

The greedy comes with other things, which has a margin of 5x (I am not saying in everything). What about the cover?

What about a BMS like Ennoid that costs 225??? (2 weeks ago maclak bought it for 180, suddenly 2 days after got increased to 200 and a day later 225, 45 is 3 days is just weird... and I think was traction...)

Or the little focer for EUR350 ($400) with the connectors in Europe. Little focer v1 cost $150 and now v3 is $300 without connectors that got increased these days after Dado's videos.

Is this acceptable.? The margin here is NOT marginal and is not just for the shortage... is more than that. It is the traction is getting for certain youtubers, and visibility, and they are incresasing the prices for convenience. As people keeps paying this is getting crazy.

I remember the days with the flaotwheel, and how cheap it was... not anymore.

-

@ed_co With how much everything has gone up I can't tell what is genuine inflation and what is just a dishonest and opportunistic price increase.

-

@ed_co https://fungineers.tech/products/hub-motor-complete-with-tyre

A six inch Xr type motor for vesc was available for presale, looks like a XR/Plus style axle , I think the price was approximately $300us. -

@lemur Obviously you can't compare with a FM hub, but from this solution (with its drawbacks) to $700-750 for just a case without any motor, i have it clear...

-

@ed_co said in GTXR conversion- version 2:

@lemur Obviously you can't compare with a FM hub, but from this solution (with its drawbacks) to $700-750 for just a case without any motor, i have it clear...

nothing wrong with outlandish imo. cost effectiveness is itself a niche concern and proving a market is expensive after all. without incentive there is no action, n the volume is super low!

ordering small runs from a 3rd party fabrication service lowers that hurdle considerably, but still pricey. the result is a relatively high-cost niche product.

the prices only come down when the market matures enough to warrant scaling up mfg or it solicits a new competitor.

-

@notsure I think that buying a hub case for 75% of the price of a pint is just ret@#€#&d (sorry for the bad word) , or you have so much money that you don't even care to burn it... Just my opinion

As a creator, if I was doing something for the sake of because I can, but doesn't scale, before putting at a price that could even be fair but completely unaccessible, I would do what Lemur said: this is not for sale, I just did for personal use. In this case, as it is so expensive that doesn't scale...

Just the option, IMHO seems excessive. Waaay to much

-

@ed_co said in GTXR conversion- version 2:

buying a hub case for 75% of the price of a pint

Yeah, it's nuts. There are certainly ways to cut those costs down and hopefully they do since it won't be long till decent motors are worth their weight in gold.

Personally I'd be casting the rough shape then milling the excess. Less material waste per unit and the milled shavings can be remelted back down to feed the next batch. Some losses in impurities but with the right skill you're not looking at that massive initial investment in material costs. That's assuming they can make a re-usable mould and aren't hand packing a sand cast every time 0.o

-

But the WORST THING that I just found out, and this is making me freak out. Is a XR/GT hub size and just the external cover will define in what could be incepted, meaning, it has the problem of not being centered!! $750 and is not even centered!! Seriously, I hope I am wrong, but...

-

@ed_co The hub is open both ends on this custom one so I think the idea is you get the hub casing then a set of the covers depending on if it goes on a GT or XR since that's where the spacing occurs.

-

@lia oh, so both ends... Gotcha. So both ends will adjust instead of just one... Just ignore what I wrote before. Well for almost the price of a pint, I couldn't expect anything less... Cheers Lia!!

-

@ed_co I'm just guessing, it's the most sensible way to do it considering the sheer cost of the thing.

I don't think I could ever use one of these even at half the price. It's practically the cost of an entire motor but the one part that can get irreparably damaged by riding rough.

Hopefully they include some stickers to sweeten the deal though ;)

-

@ed_co I think it will be centered because there are two end covers, one on each side so they can change the offset any way they want . But this is really overkill, this started as a $10 shim and morphed into a high dollar hub, which will prove a little useless when the 6.5" TFL Endouro tire comes out.

I can see if Tech Rails had a controller other than a vesc that can outperform the GT and build a high end board for the people who can afford it , much like a high end car. -

@lemur with all your machining capabilities, are you able to do one hub for yourself? Or you don't have the necessary required equipment to do it? Would love to see it from someone that I respect which is not trying to abuse from people and through bait just for fishing someone stupid enough to buy it

-

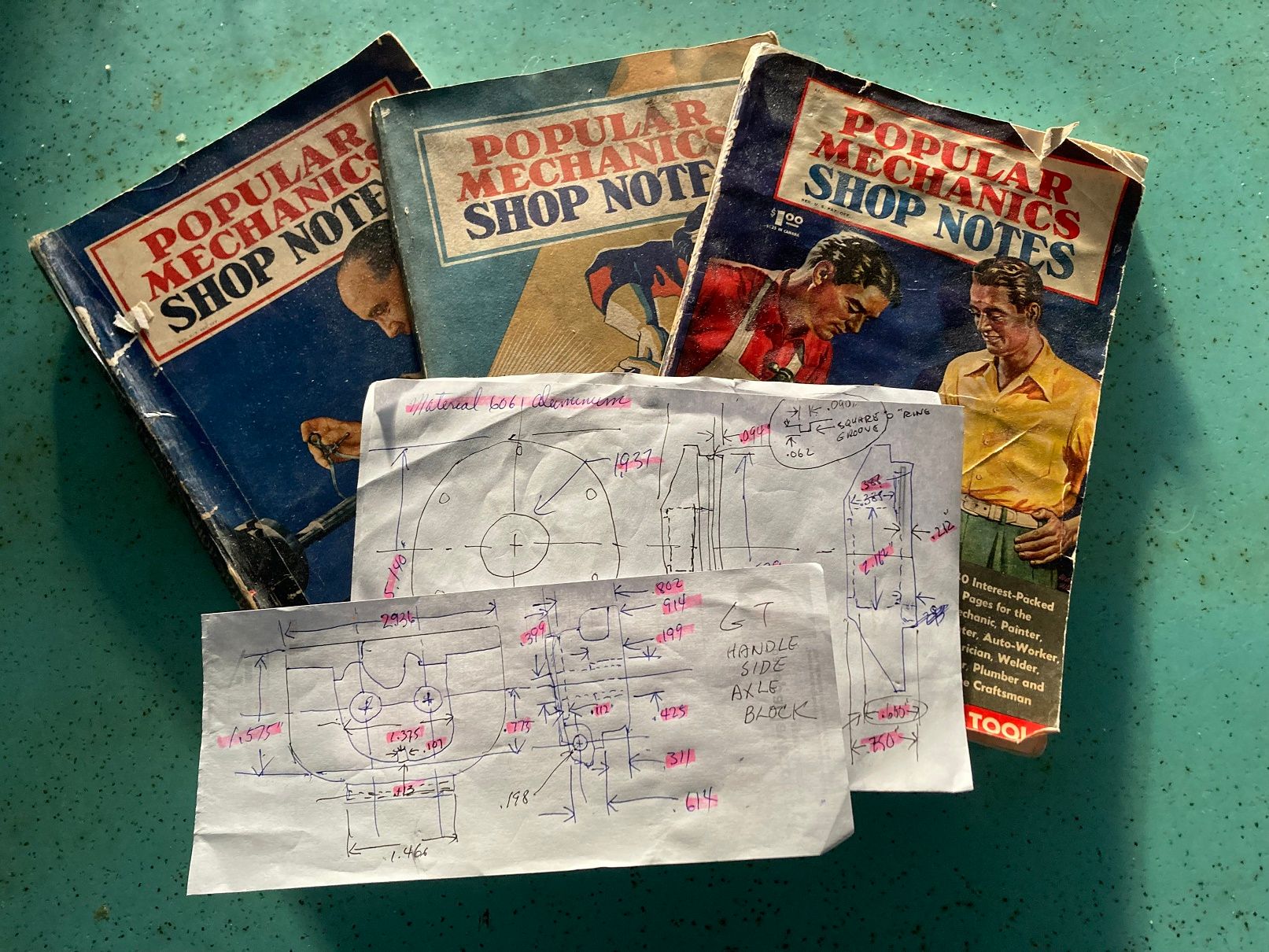

@ed_co It's not the machining, it's the 6061 billet cost , magnets and the time involved to machine a hub , any mistake and probably $300 billet ends up as a barrelful of shavings.

A cast blank ends up no better than the stock hub anyways. I'm totally happy with the shim and offset axle block, although I have a billet end cover ready to go with an added oil seal to boot.

I was going to suggest to Tech Rails that they add seals, but no point if they can' think ahead. -

@lemur Do you have the cover and the mounts designed in a file?

-

@ed_co Sorry, these parts were a one off and plans and dimensions were hand drawn on scape pieces of paper. I'm the last of old school , I always liked the way things were done before cnc and cad, but I also embrace high tech.