Onewheel GT 6.5 inch tire solution (hopefully)

-

A few people are hoping that the Gt motor rotor will interchange with the XR/Plus rotor and we can put 6 inch tires on the GT.

I only have one extra XR motor but a few people have hoarded quite a few motors, won't be long now.

-

@lemur Eager to see if this actually works. In theory there shouldn't be an issue assuming nothing truly changed.

When is your GT expected to show up?

-

@lia The shipping date is still at Jan 24, but could change.

-

@lemur Nice, mine's the 27th.

Being as close as we are to the shipping date I'm cautiously optimistic those delays people have mentioned are purely on additional parts for later orders.

I eagerly await an update on how this goes :)

If it works I might be buying out some XR motors from PinkOak while they still have them. -

@lia Definitely not accurate, but I compared pictures of the GT and PX on the same relative scale and used a digital caliper to measure the bolt hole spacing, they look close enough and are 7 bolts.

Pint or PInt X stators are the same dimensions as XR/Plus. -

@lemur You don't by chance have the ability to do (or know of someone that has done) aluminium casting?

Was thinking the other day if the worst occurs and an XR hub casing won't slot on it's not super out of reach for someone with the gear to actually cast custom hubs and fit magnets inside.The 2 main hurdles would seemingly be having a model to perform some sort of "lost casting" and the second being both balancing magnetic strength and the mass of the hub after.

I'd be down to 3D model a replica hub (but with a 6" rim) for a "lost PLA cast" if this seems at all do-able. That would just leave someone with the gear to turn a plastic model to aluminium with a pour and post process it.

Spitballing the idea, my optimism stems purely from watching way too many casting video's over a few years having always wanted to try it. Curious if the idea sounds feasible to you (or anyone else reading).

-

@lia I can probably get someone to cnc machine a hub from billet , but probably expensive.

Casting is the least expensive and can be cnc afterwards or manually machined as a one-off.

Most of the local foundries have closed in my area, but there are a couple still around, we just need a mold.

I still think we can interchange rotors.

Two more weeks and I'll know if my shipping date holds.

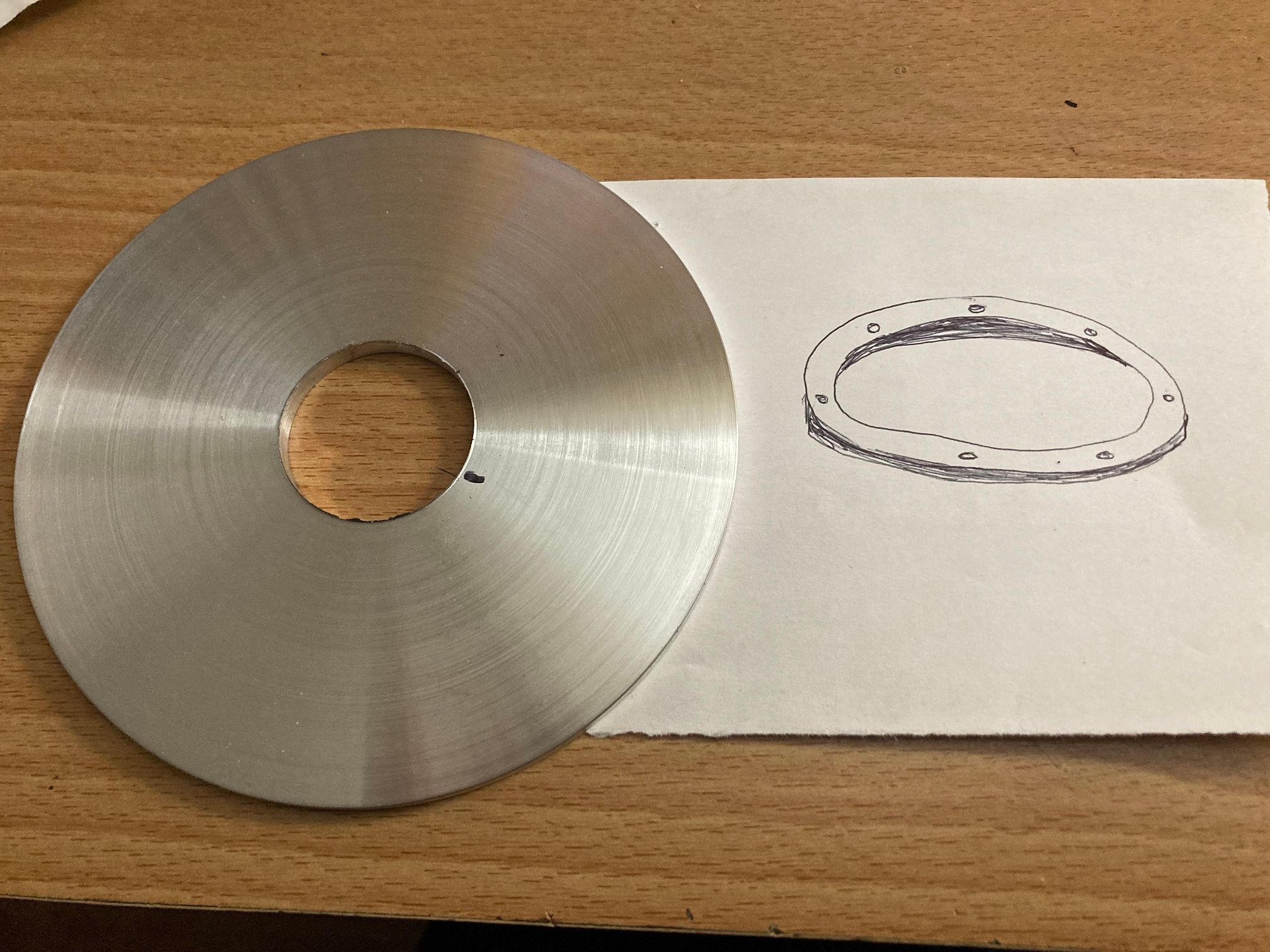

I know you're great at creating 3d models and love your work.![IMG_5033[1].PNG](/assets/uploads/files/1642126105342-img_5033-1.png)

-

@lia Here's an idea, how about a 3 piece hub with bolt on rim flanges sealed with "o" rings. Easier to cast and if the rim gets damaged, it can be replaced. Also so much easier to change a tire, just remove one rail, unbolt one flange, re and re tire. Rim flanges can be 6.5 or 6 inch to suit your requirements.

If I had the cast cores, I can machine a prototype.

I may consider machining that using billet center and flanges at a later date. -

@lemur That sounds like a much better idea. Much more robust in utility and easier to make reliably.

Eagerly awaiting the next 2 weeks.

-

Images from FM suggest the motor plate might be the same size on a GT as on an XR. See the width of the lip on the inside of the wheel, before the motor plate. On an XR, the shape is different, but I don't think the space taken up by the lip here is as large. If the motor plate and axle are the same size, then the posibility of an XR wheel replacing the GT wheel exists.

-

@lia Not my idea, but the second idea is mine.

-First is a spacer ring to make up for the difference in the bearing shoulder. I machined a blank, but I need final dimensions.

-Second is a adapter to center the GT stator/axle in my lathe so I can machine the GT bearing shoulder.

-

@lemur Finished the Gt rim adapter, I made it 0.054" thick instead of 0.050" because I can always shim to get the proper end play like OW does. I just to make sure I don't brick the GT if I remove the motor.

-

@lemur Oh I get it now, was so confused at first but this makes sense. Instead of modifying the GT stator by shaving off that extended lip you're just shimming the hub plate to it can sit on the extended lip.

That is so clever, I'd have never thought to do it that way! This is by far the best and least destructive method and I love it.

-

@lia Just scared to tear apart my GT right now. Haha.

-

@lemur said in Onewheel GT 6.5 inch tire solution (hopefully):

@lia Just scared to tear apart my GT right now. Haha.

lol yeah that hub may be rigged man. imagine that... the hall sensors maybe?

-

@lemur I don't blame you, I was eager to crack mine open after my first ride but now I'm reconsidering it.

As much as I love to tinker I'm in no position to be a canary for the next potential FM boobytrap.

That said once things settle a little I'll probably build up the courage to pop it open.

-

@lia It's an expensive board to be messing around with right now especially with so many unknowns . Having said that, I'm trying to source a Torx plus 45 for the rails. Haha.

-

@lemur said in Onewheel GT 6.5 inch tire solution (hopefully):

I'm trying to source a Torx plus 45 for the rails.

No way they used a 45??? My set only goes up to 40 D:

-

@lemur I think Bob Nicolson took apart his GT but never unplugged the battery or bms, but the red light of death came on when he tried to power it up later, although he managed to get to work later.

Maybe he never hooked up the motor when he powered it up and maybe the controller goes through a systems check before giving the go ahead. I know cars and bikes do that. -

@lemur Possibly, I was surprised when doing diagnostics on my XR that you can get aways with just the controller, BMS and battery to load into an active state. Sort of thought the lack of motor would throw an error, maybe that's what they've done here.

Do we have any confirmed reports of the GT throwing specific error codes anymore at all actually? I'm curious if they kept that since it's the only way we know what to look for when fault finding currently.